Light trapping structure based on nano-zinc oxide silicon heterojunction battery, and preparation method of the light trapping structure

A nano-zinc oxide and silicon heterojunction technology, used in circuits, photovoltaic power generation, electrical components, etc., can solve the problem of not meeting the light trapping effect of solar cells, and achieve the effect of reduced integral reflection and low reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

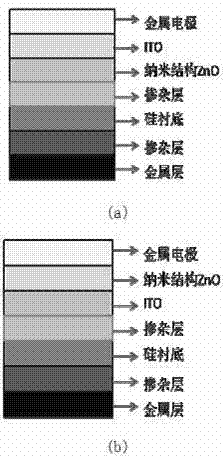

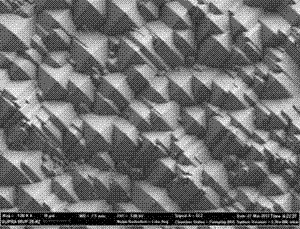

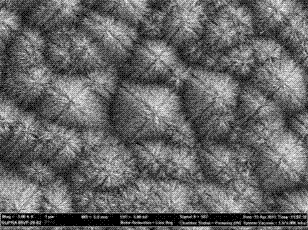

[0022] A method for preparing a light-trapping structure based on a nano-zinc oxide-silicon heterojunction cell, using wet etching to prepare a pyramid shape, using a solution dipping method to prepare a seed layer, and hydrothermally forming a zinc oxide nanocolumn or nanocone growth, and obtained a new light-trapping structure with high-efficiency light-trapping effect. The light-trapping structure includes: a silicon substrate with a pyramidal shape prepared by wet etching, a ZnO seed layer, and zinc oxide nanocolumns grown on the seed layer. The seed layer is zinc oxide grains formed by the dehydration of zinc acetate, with a thickness of 15nm. The zinc oxide nanocolumns grow on the seed layer along the C-axis perpendicular to the substrate, with a length of 600nm and a diameter of 70nm. The specific steps are as follows:

[0023] 1) Ultrasonic cleaning of (100) silicon wafers with acetone and alcohol for 5 minutes, and then pre-cleaning the cleaned silicon wafers with 10wt...

Embodiment 2

[0030] A method for preparing a light-trapping structure based on a nano-zinc oxide-silicon heterojunction cell, using wet etching to prepare a pyramid shape, using a solution dipping method to prepare a seed layer, and hydrothermally forming a zinc oxide nanocolumn or nanocone growth, and obtained a new light-trapping structure with high-efficiency light-trapping effect. The light-trapping structure includes: a silicon substrate with a pyramidal shape prepared by wet etching, a ZnO seed layer, and zinc oxide nanocolumns grown on the seed layer. The seed layer is zinc oxide crystal grains formed by the dehydration of zinc acetate, with a thickness of 15nm. The zinc oxide nanocolumns grow on the seed layer along the C-axis perpendicular to the substrate, with a length of 800nm and a diameter of 50nm. Specific steps are as follows:

[0031] 1), 2) are the same as embodiment 1;

[0032] 3) Prepare 200mL of a mixture of zinc nitrate and hexamethylenetetramine as the growth solu...

Embodiment 3

[0036] A method for preparing a light-trapping structure based on a nano-zinc oxide-silicon heterojunction cell, using wet etching to prepare a pyramid shape, using a solution dipping method to prepare a seed layer, and hydrothermally forming a zinc oxide nanocolumn or nanocone growth, and obtained a new light-trapping structure with high-efficiency light-trapping effect. The light-trapping structure includes: a silicon substrate with a pyramidal shape prepared by wet etching, a ZnO seed layer, and a zinc oxide nanocone grown on the seed layer. The seed layer is zinc oxide grains formed by the dehydration of zinc acetate, with a thickness of 10nm. The zinc oxide nanocone grows on the seed layer along the C-axis perpendicular to the substrate, with a length of 300nm and a diameter of 80nm. Specific steps are as follows:

[0037] 1) Ultrasonic cleaning of (100) silicon wafers with acetone and alcohol for 5 minutes, and then pre-cleaning the cleaned silicon wafers with 10wt% NaOH...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com