Preparation method of konjac glucomannan/heteropoly acid composite proton conductive film

A proton-conducting membrane and mannan technology, which is applied to fuel cell components, solid electrolyte fuel cells, circuits, etc., can solve problems such as restrictions on large-scale commercial applications, reduced proton conductivity, and complicated preparation processes, and achieve Superior chemical and thermal stability, improved proton conductivity, and improved alcohol resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

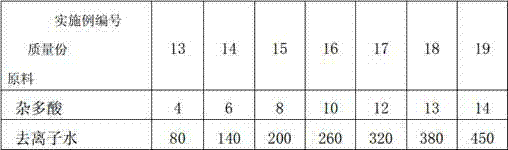

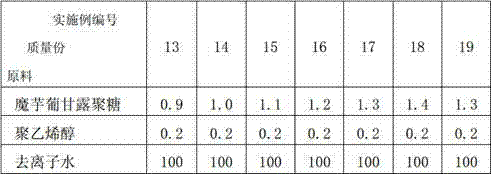

Examples

Embodiment 1

[0025] The preparation method of konjac glucomannan / heteropolyacid composite proton conductive membrane comprises the following steps:

[0026] Add 1.0 g of purified konjac glucomannan and 0.2 g of polyvinyl alcohol into 100 g of deionized water, stir at room temperature until the solid is dissolved, and then add a small amount of NaOH dropwise to adjust the pH of the solution to 10.0. Raise the temperature to 60°C, heat for 3 hours to mix the solution evenly, let it stand for 24 hours, defoam, cast on a clean glass plate to form a film, and then dry the glass plate with film at 60°C for 8 hours , peel off the film from the glass plate to obtain the konjac glucomannan-based film;

[0027] Take 5.0 g of phosphotungstic acid in 100 g of deionized water, mix, and prepare an aqueous solution of phosphotungstic acid;

[0028] Soak the prepared konjac glucomannan-based membrane in the aqueous solution of phosphotungstic acid for 24 hours, take it out and dry it at 60°C for 6 hours,...

Embodiment 2

[0032] The preparation method of konjac glucomannan / heteropolyacid composite proton conductive membrane comprises the following steps:

[0033] Add 0.8 g of purified konjac glucomannan and 0.2 g of polyvinyl alcohol into 100 g of deionized water, stir at room temperature until the solid is dissolved, and then add a small amount of NaOH dropwise to adjust the pH of the solution to 10.0. Raise the temperature to 60°C, heat for 3 hours to mix the solution evenly, let it stand for 24 hours, defoam, cast on a clean glass plate to form a film, and then dry the glass plate with film at 60°C for 8 hours , peel off the film from the glass plate to obtain the konjac glucomannan-based film;

[0034] Take 5.0 g of phosphotungstic acid in 100 g of deionized water, mix, and prepare an aqueous solution of phosphotungstic acid;

[0035] Soak the prepared konjac glucomannan-based membrane in the aqueous solution of phosphotungstic acid for 24 hours, take it out and dry it at 60°C for 6 hours,...

Embodiment 3

[0039] The preparation method of konjac glucomannan / heteropolyacid composite proton conductive membrane comprises the following steps:

[0040]Add 1.3 g of purified konjac glucomannan and 0.2 g of polyvinyl alcohol into 100 g of deionized water, stir at room temperature until the solid is dissolved, then add a small amount of NaOH dropwise to adjust the pH of the solution to 10.0. Raise the temperature to 60°C, heat for 3 hours to mix the solution evenly, let it stand for 24 hours, defoam, cast on a clean glass plate to form a film, and then dry the glass plate with film at 60°C for 8 hours , peel off the film from the glass plate to obtain the konjac glucomannan-based film;

[0041] Take 5.0 g of phosphotungstic acid in 100 g of deionized water, mix, and prepare an aqueous solution of phosphotungstic acid;

[0042] Soak the prepared konjac glucomannan-based membrane in the aqueous solution of phosphotungstic acid for 24 hours, take it out and dry it at 60°C for 6 hours, soak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com