Yellow mushroom standardized component manufacturing method and application of components to treatment of lung cancer

A technology for the production of yellow mushrooms, which is applied in the fields of biochemical equipment and methods, drug combinations, and microorganism determination/inspection, etc., can solve the problem of little research on the chemical composition of yellow mushrooms, and achieves expansion of raw material sources, easy judgment, and technology. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1 The preparation method of standardized components of chanterelles comprises the following steps:

[0034] ⑴After drying and crushing the chanterelles, extract 3 times with analytical pure water at 40°C according to the solid-liquid ratio of 1g:4mL, and centrifuge to collect the fungus residue, which is mixed with acetone at a ratio of 1g:1mL Extract at 10°C for 3 times, each time for 72 hours, and collect the filtrate by centrifugation; the filtrate is concentrated under reduced pressure to a paste under the conditions of a vacuum of 0.03 MPa and a temperature of 30°C to obtain the acetone extract.

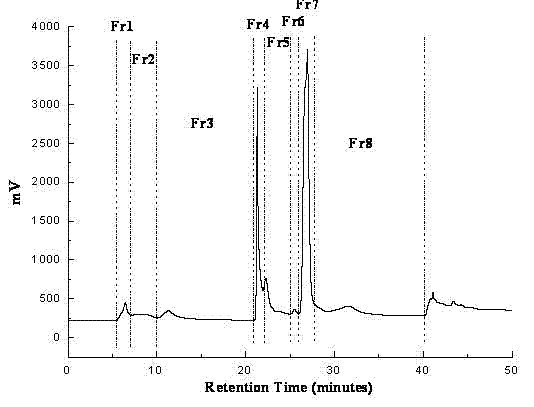

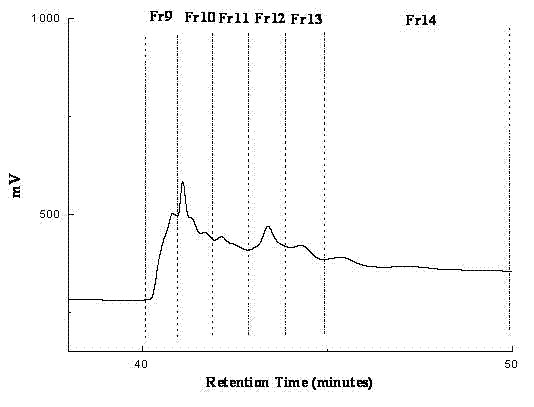

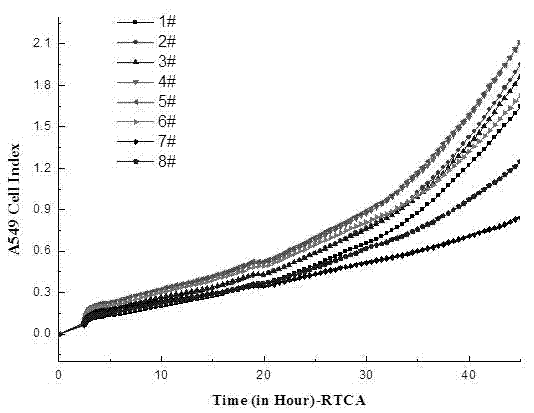

[0035] (2) Add 1 times its volume of n-hexane-ethyl acetate mixture to the acetone extract to dissolve, and pass through a 0.45 μm organic filter to obtain a sample solution containing acetone extract; 10μm silica gel is used as the separation matrix to prepare chromatographic separation to obtain 14 standardized component samples of Fr1, Fr2, Fr3, Fr4, Fr5,...

Embodiment 2

[0046] Example 2 The preparation method of standardized components of chanterelles comprises the following steps:

[0047] ⑴After drying and crushing the chanterelle mushrooms, extract them with analytically pure water at 90°C for 3 times at a solid-liquid ratio of 1g:20 mL, each time for 1 hour, and collect the fungus residue by centrifugation. The ratio of solid to liquid was extracted at 80°C for 3 times, each time for 5 hours, and the filtrate was collected by centrifugation; the filtrate was concentrated under reduced pressure to a paste under the conditions of a vacuum of 0.1 MPa and a temperature of 80°C to obtain the acetone extract.

[0048] (2) Add 6 times its volume of n-hexane-ethyl acetate mixture to the acetone extract to dissolve, and pass through a 0.45 μm organic filter to obtain a sample solution containing acetone extract; 10μm silica gel is used as the separation matrix to prepare chromatographic separation to obtain 14 standardized component samples ...

Embodiment 3

[0052] Example 3 The preparation method of standardized components of chanterelles comprises the following steps:

[0053] After drying and crushing the chanterelles, extract them with analytically pure water at 65°C for 3 times according to the solid-liquid ratio of 1g:12mL, and centrifuge to collect the fungus residue, which is mixed with acetone at the ratio of 1g:10mL. The liquid ratio was extracted at 45°C for 3 times, each time for 38 hours, and the filtrate was collected by centrifugation; the filtrate was concentrated under reduced pressure to a paste under the conditions of a vacuum of 0.06 MPa and a temperature of 55°C to obtain the acetone extract.

[0054] (2) Add 3.5 times its volume of n-hexane-ethyl acetate mixture to the acetone extract to dissolve, pass through a 0.45 μm organic filter to obtain a sample solution containing acetone extract; 10μm silica gel is used as the separation matrix to prepare chromatographic separation to obtain 14 standardized co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com