Method for recovering ilmenite from dense difficult to dissociate vanadium titano-magnetite

A vanadium-titanium magnetite and titanium recovery technology, applied in chemical instruments and methods, magnetic separation, solid separation, etc., to achieve good recovery effect, reduce loss, and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

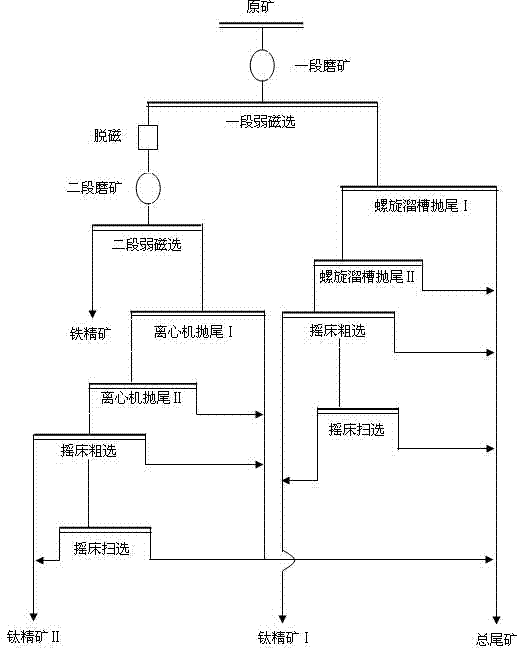

Image

Examples

Embodiment 1

[0044] Titanium-containing minerals are mainly titanomagnetite and ilmenite, and gangue minerals are mainly quartz, ordinary pyroxene and plagioclase. The original ore of vanadium-titanium magnetite is crushed and evenly divided to below -2mm, and the grinding concentration is 50%-60%. After a stage of grinding, a stage of magnetic separation and demagnetization are carried out to obtain a section of iron coarse concentrate and a section of tailings , a section of tailings is used as titanium ore for beneficiation.

[0045] The first-stage iron coarse concentrate is subjected to the second-stage grinding, and then the second-stage magnetic separation is carried out to obtain the iron concentrate and the second-stage tailings, and the second-stage tailings are used as ore for titanium selection.

[0046] After the tailings of the first stage are sorted, the ilmenite concentrate I is obtained.

[0047] After the tailings of the second-stage magnetic separation are sorted, the i...

Embodiment 2

[0050] Using vanadium-titanium magnetite in Quebec, Canada, its raw ore grade is Fe 44.16%, TiO 2 10.87%, the ore is characterized by extremely fine particle size, difficult to dissociate, and requires fine grinding. Crushing and screening the vanadium-titanium-magnetite raw ore to -2mm, after a stage of grinding, the fineness of the vanadium-titanium-magnetite raw ore is ground to -0.074mm, and the vanadium-titanium-magnetite ore with a fineness of -0.074mm accounts for 73.01 %.

[0051] Under the condition of the magnetic field strength of 0.10-0.18T, the vanadium-titanium ferromagnetite with a fineness of -0.074mm is wet magnetically separated, and the demagnetizer is demagnetized under the condition of the field strength of 150-165KA / m to obtain a section Iron coarse concentrate, the Fe grade of this section of iron coarse concentrate is 51.74%, the recovery rate is 94.48%, and the tailings of the first section are used as ore for titanium selection.

[0052]The first-st...

Embodiment 3

[0057] The original ore of Jinping vanadium-titanium magnetite in Yunnan contains 36.10% Fe, TiO 2 8.44%, the ore is characterized by fine particle size embedded distribution, difficult dissociation, need fine grinding. Crushing and screening the vanadium-titanium magnetite raw ore to -2mm, after a stage of grinding, the fineness of the vanadium-titanium magnetite raw ore is ground to -0.074mm, and the vanadium-titanium ferromagnetic ore with a fineness of -0.074mm accounts for 70.55 %.

[0058] Under the condition that the magnetic field intensity is 0.10-0.18T, the vanadium-titanium ferromagnetite with a fineness of -0.074mm is magnetically separated to obtain a section of iron coarse concentrate, the Fe grade of this section of iron coarse concentrate is 53.56%, and the recovery The rate is 90.32%, and the first section of tailings is used as titanium ore for beneficiation.

[0059] The first-stage iron coarse concentrate is ground in the second stage until the grinding f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Magnetic field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com