A kind of novel sludge coal-water slurry and preparation method thereof

A technology for sludge water and sludge, which is applied in the field of new sludge coal water slurry and its preparation, can solve the problems of low concentration of finished coal water slurry sludge and coal slurry, save chemical raw materials, and solve the problem of less addition or concentration The effect of too low and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1, prepare sludge coal-water slurry

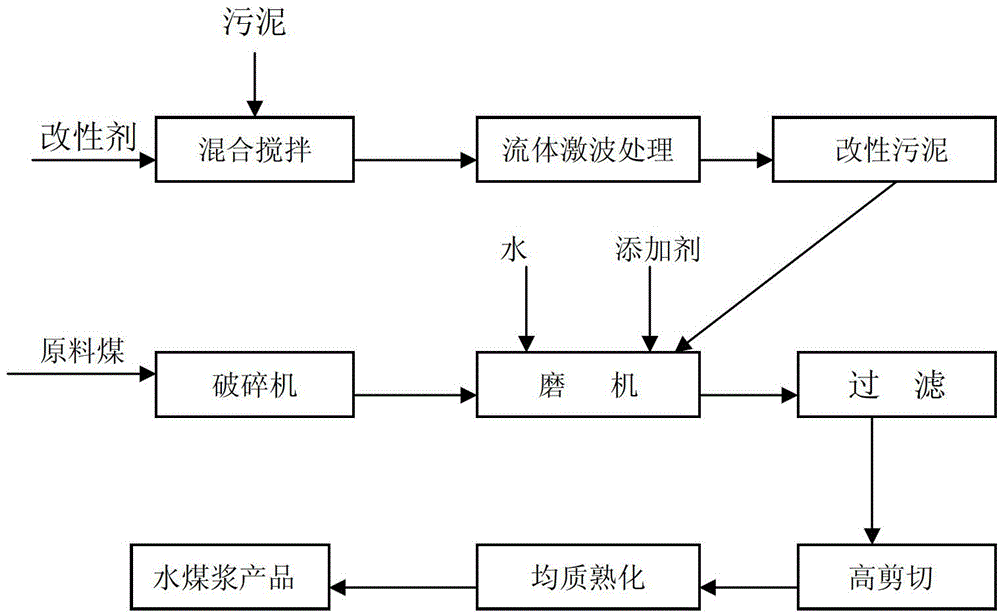

[0027] The preparation flow chart is as figure 1 shown.

[0028] The raw materials used in this embodiment are as follows:

[0029] Raw coal for pulping is bituminous coal with a total water content of 6%; the sludge used is sludge from a sewage treatment plant in Shenzhen with a water content of 70%; the modifier is black liquor discharged from a paper mill in Henan, and the additive is Sodium lignosulfonate. The specific process of pulping is as follows:

[0030] (1) Send the sludge and black liquor into the sludge mixing tank at a mass ratio of 7:3 to obtain a mixture, add twice the amount of water to the mixture, and stir the mixture for 10 minutes at a stirring speed of 1000 rpm. The sludge and modifier are fully mixed to obtain a mixed solution.

[0031] (2) Send the mixed solution in step (1) into a homogenizer, and modify the mixture at a pressure of 40 MPa to obtain a modified sludge with low viscosity and g...

Embodiment 2

[0036] Embodiment 2, prepare sludge coal-water slurry

[0037] The preparation flow chart is as figure 1 shown.

[0038] The raw materials used in this embodiment are as follows:

[0039] Raw coal for pulping is anthracite, with a total water content of 10.5%; the sludge used is sludge from a sewage treatment plant in Hebei, with a water content of 80%; modifiers are sodium hydroxide and hydrogen peroxide, and additives are modified wood Sodium Sulfonate. The specific process of pulping is as follows:

[0040] (1) Send sludge, sodium hydroxide, and hydrogen peroxide into the sludge mixing tank at a mass ratio of 100:1:0.1 to obtain a mixture, add twice the amount of water to the mixture, and stir the mixture at a stirring speed of 1000 rpm After 10 minutes, the sludge and the modifier are fully mixed to obtain a mixed solution.

[0041] (2) Send the mixed solution in step (1) into a homogenizer, and modify the mixture at a pressure of 50 MPa to obtain a modified sludge wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com