Method for preparing dandelion absolute oil and application of dandelion absolute oil in cigarettes

A dandelion and cigarette technology, applied to dandelion oil and its application in tobacco, can solve the problems affecting the smoking quality of cigarette products, high impurity content of plant extracts, and difficulty in cutting dandelion into silk, etc., and achieve product quality The effect of stable and easy control, abundant production raw materials, and easy availability of production raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

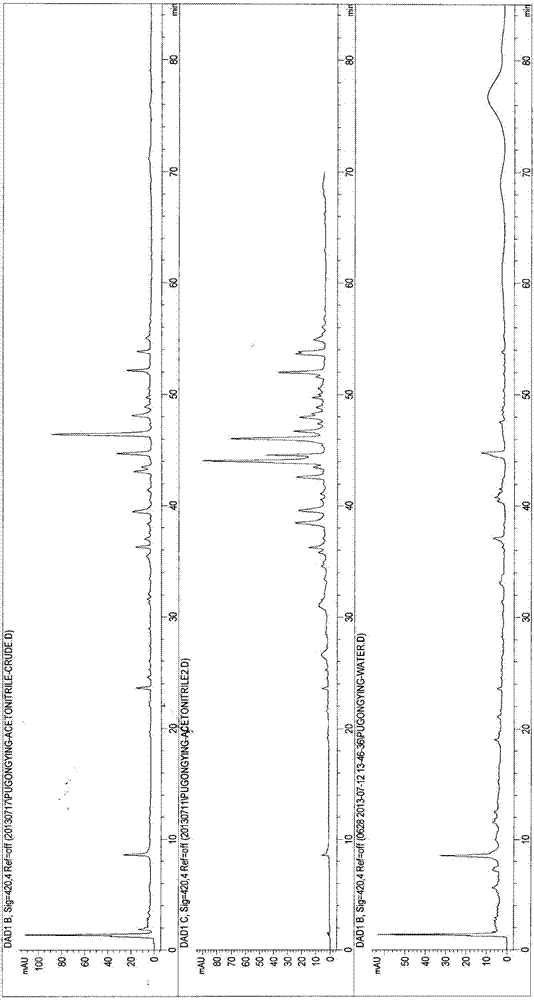

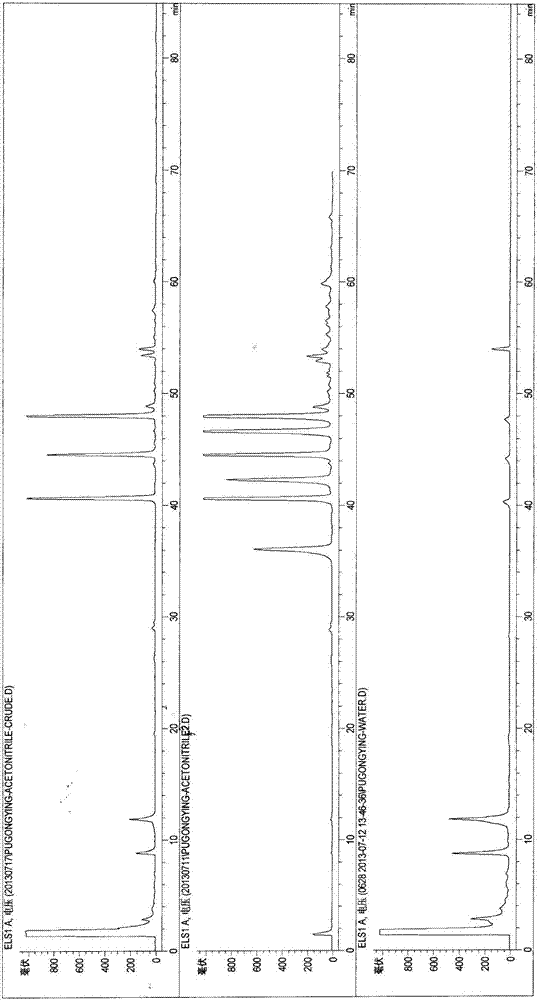

Image

Examples

example 1

[0019] Take 0.8 kg of dried and crushed aerial parts of dandelion, heat them with 95% ethanol at 70°C to extract twice, the ratio of solid to liquid is 1:4 and 1:3 respectively, and a total of 4.2 kg of extract is obtained. The extract was concentrated to 617 g under reduced pressure, the vacuum degree was -0.09 MPa, and the temperature of the water bath did not exceed 50 °C. The concentrated solution was refrigerated and left to stand for 2 hours, vacuum filtered with a micron filter membrane, and the filter residue was washed with a small amount of ethanol to obtain a total of 699 g of filtrate. The filtrate after dewaxing is further concentrated under reduced pressure until it has no alcohol smell. At this time, the concentrated liquid presents two immiscible phases. It is placed in a liquid separation device and allowed to stand fully. The lower water phase is a clear dark brown liquid, and the upper layer is The oil phase is a viscous opaque liquid extract, but since the ...

example 2

[0021] 25 kg of dried whole dandelion herb purchased in the Chinese herbal medicine market, crushed to about 20 meshes; using a steam heating extraction tank with a volume of 200 L to extract twice, adding 80% ethanol 5 times and 4 times the weight of the raw material respectively, heating After the temperature stabilized to 60°C, count the time and extract for 2 hours each time; a total of 196 kg of extract was obtained. Concentrate the extract solution to 15 kg with an external circulation evaporator, the vacuum degree is -0.08 MPa, and the temperature is 40-45 °C. Put the concentrated solution in a cold storage (0-6°C) and let it stand overnight. Immediately after taking it out, use a three-legged centrifuge to dewax it, and obtain 12.8 kg of dewaxed filtrate. The filtrate was concentrated under reduced pressure using a rotary evaporator with a volume of 20 L, the vacuum degree was -0.09 MPa, and the temperature was not higher than 65 °C, and about 4 kg of the concentrated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com