Super-hydrophilic antireflection coating preparation method and super-hydrophilic antireflection coating

A super-hydrophilic coating technology, applied in the field of super-hydrophilic anti-reflective coatings, can solve the problems of coating strength and self-cleaning properties, inability to ensure complete removal of CTAB, unsatisfactory hydrophilic properties of coatings, etc., to achieve Wide application range, low cost and obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Mix 21~23mL of tetraethyl orthosilicate, 21~23mL of absolute ethanol, 1~2mL of water and 4×10 -4 ~6×10 -4 Mix mL of hydrochloric acid, part of the tetraethyl orthosilicate is hydrolyzed under acidic conditions, and stir at a temperature of 50°C~70°C for 80~100 minutes to obtain SiO 2 sol, the resulting SiO 2 The sol is cooled to room temperature; to the obtained SiO 2 Add 6-8mL of hydrochloric acid, 0.3-0.5mL of water and 45-47mL of absolute ethanol to the sol to continue hydrolysis of the remaining tetraethyl orthosilicate; when SiO 2 When the concentration of the sol reaches 9~11mol / L, after stirring at room temperature for 10~15 minutes, aging SiO at a temperature of 40°C~60°C 2 Sol for 2~4 hours; then add 105~107mL of absolute ethanol to dilute to obtain reagent; add surfactant cetyltrimethylammonium bromide (CTAB) to the obtained reagent, make CTAB The mass fraction content is 1.5%, and it is fully stirred for 30-90 minutes to obtain a transparent SiO with ...

Embodiment 2

[0046] Substantially adopt the same method as Example 1 to prepare a glass sheet sample with a high-strength super-hydrophilic anti-reflective coating on the surface, the difference is that:

[0047] In step (1), CTAB was added to the obtained reagent so that the mass fraction of CTAB in the reagent was 2.0%.

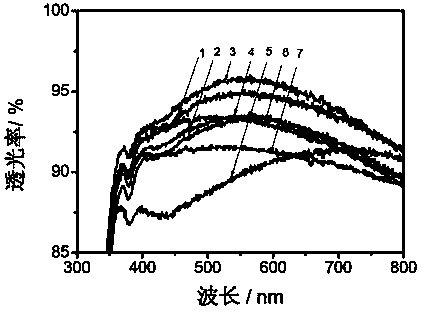

[0048] The obtained sample of the glass sheet with a high-strength super-hydrophilic anti-reflection coating attached to its surface is designated as A3. The light transmittance of the sample is as figure 1 Shown in line 2.

Embodiment 3

[0050] Substantially adopt the same method as Example 1 to prepare a glass sheet sample with a high-strength super-hydrophilic anti-reflective coating on the surface, the difference is that:

[0051] In step (1), CTAB was added to the obtained reagent so that the mass fraction of CTAB in the reagent was 2.5%.

[0052] The obtained sample of the glass sheet with a high-strength super-hydrophilic anti-reflection coating attached to its surface was designated as A4. The light transmittance of the sample is as figure 1 Indicated by midline 3. As can be seen from the figure, the light transmittance can reach 95.9%. Prepared SiO 2 TEM images of solid spherical nanoparticles such as figure 2 As shown in a, 2b is a partially enlarged TEM image of 2a. SiO in A4 sample 2 The particle size statistical histogram of solid spherical nanoparticles is shown in image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com