An In-Situ Plasma Glow Treatment Method for Improving the Field Emission Properties of Tungsten Oxide Nanomaterial Thin Films

A material thin film and plasma technology, applied in discharge tubes, electrical components, circuits, etc., can solve problems such as differences in structure and physical properties, achieve simple equipment, low method cost, and improve field emission characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

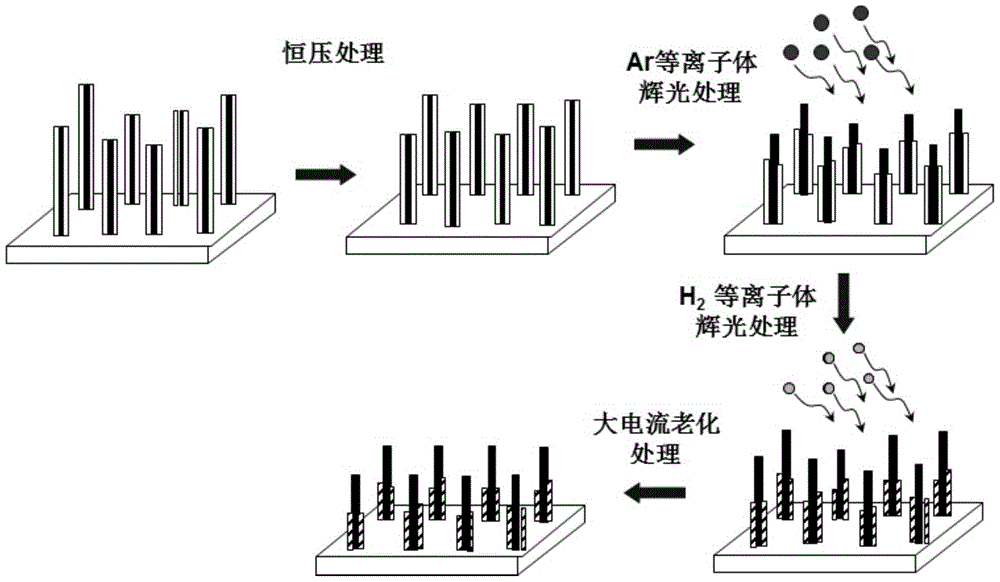

Method used

Image

Examples

Embodiment 1

[0034] Example 1: In-situ plasma process processing a sample of tungsten oxide nanowire thin film with poor uniformity

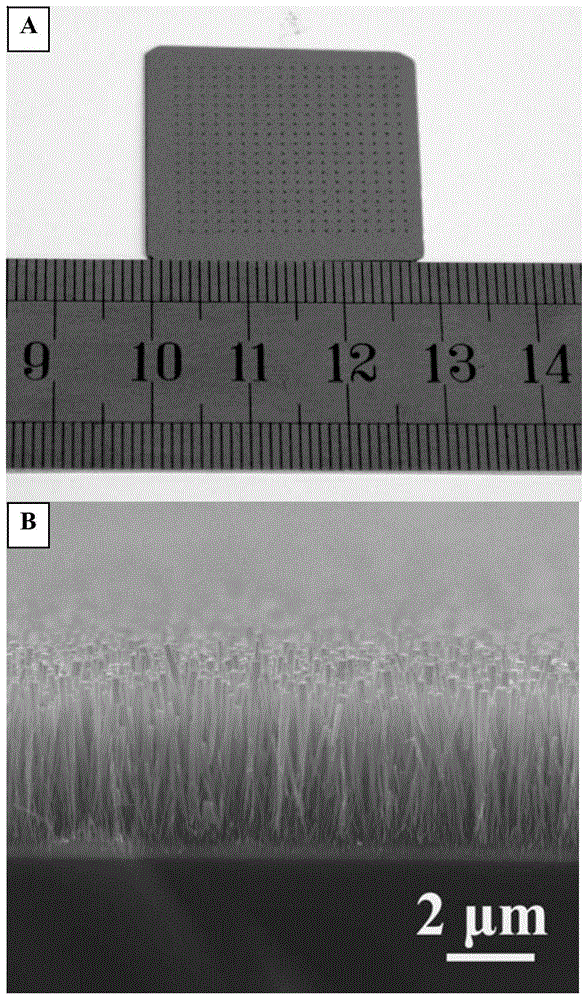

[0035] The sample 1 of the tungsten oxide nanowire thin film with poor emission uniformity prepared by the thermal evaporation growth method was treated with an in-situ plasma process. The total area of the substrate is 2.8×2.8cm 2 , The shape of the nanowire pattern is circular and the diameter is 300μm. Since there are 18 nanowire patterns in each row and column on the substrate, the total number of nanowire patterns on the substrate is 324, and the total emission area is 0.229cm 2 .

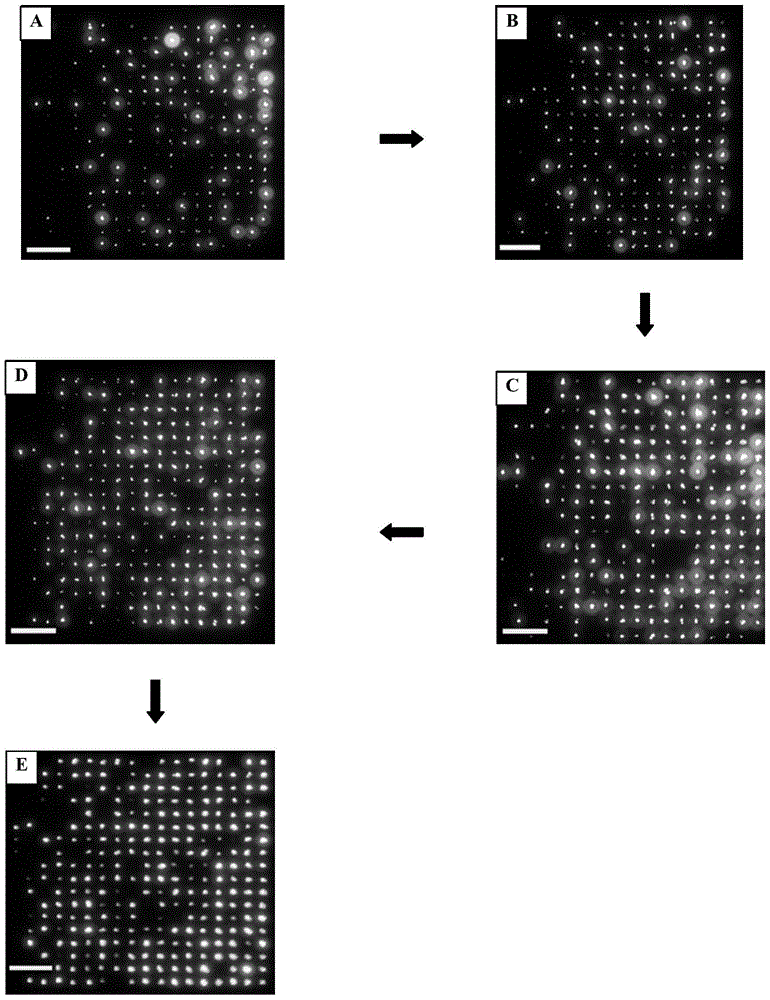

[0036] First, the patterned tungsten oxide nanowire array (sample 1, seen in figure 2 ) As the cathode of the two-pole field emission structure, it is placed in a high vacuum chamber. The anode is a phosphor screen coated with phosphor, the distance between the anode and cathode is 400μm, and the background vacuum of the system is 2.0×10 -5 Pa. From image 3 It can be found ...

Embodiment 2

[0042] Example 2: In-situ plasma process processing a sample of tungsten oxide nanowire film with poor uniformity

[0043] The in-situ plasma process was used to treat the sample 2 of the tungsten oxide nanowire thin film prepared by the thermal evaporation growth method with good emission uniformity, further verifying the feasibility of this in-situ plasma treatment process. The total area of the substrate is 2.8×2.8cm 2 , The shape of the nanowire pattern is circular and the diameter is 300μm. Since there are 18 nanowire patterns in each row and column on the substrate, the total number of nanowire patterns on the substrate is 324, and the total emission area is 0.229cm 2 .

[0044] Similarly, the patterned tungsten oxide nanowire array (sample 2) was used as the cathode of the diode field emission device and placed in the high vacuum chamber. The anode is a phosphor screen coated with phosphor, the distance between the anode and cathode is 400μm, and the background vacuum of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com