Wide-spectrum light source for fiber-optic gyroscope and manufacturing method thereof

A wide-spectrum light source and fiber optic gyroscope technology, which is applied in the field of wide-spectrum light source for fiber optic gyroscopes and its production, can solve the problems of low output power, poor spatial coherence, and poor wavelength stability of SLD, and achieve miniaturization, low cost, and light source The effect of spectral width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

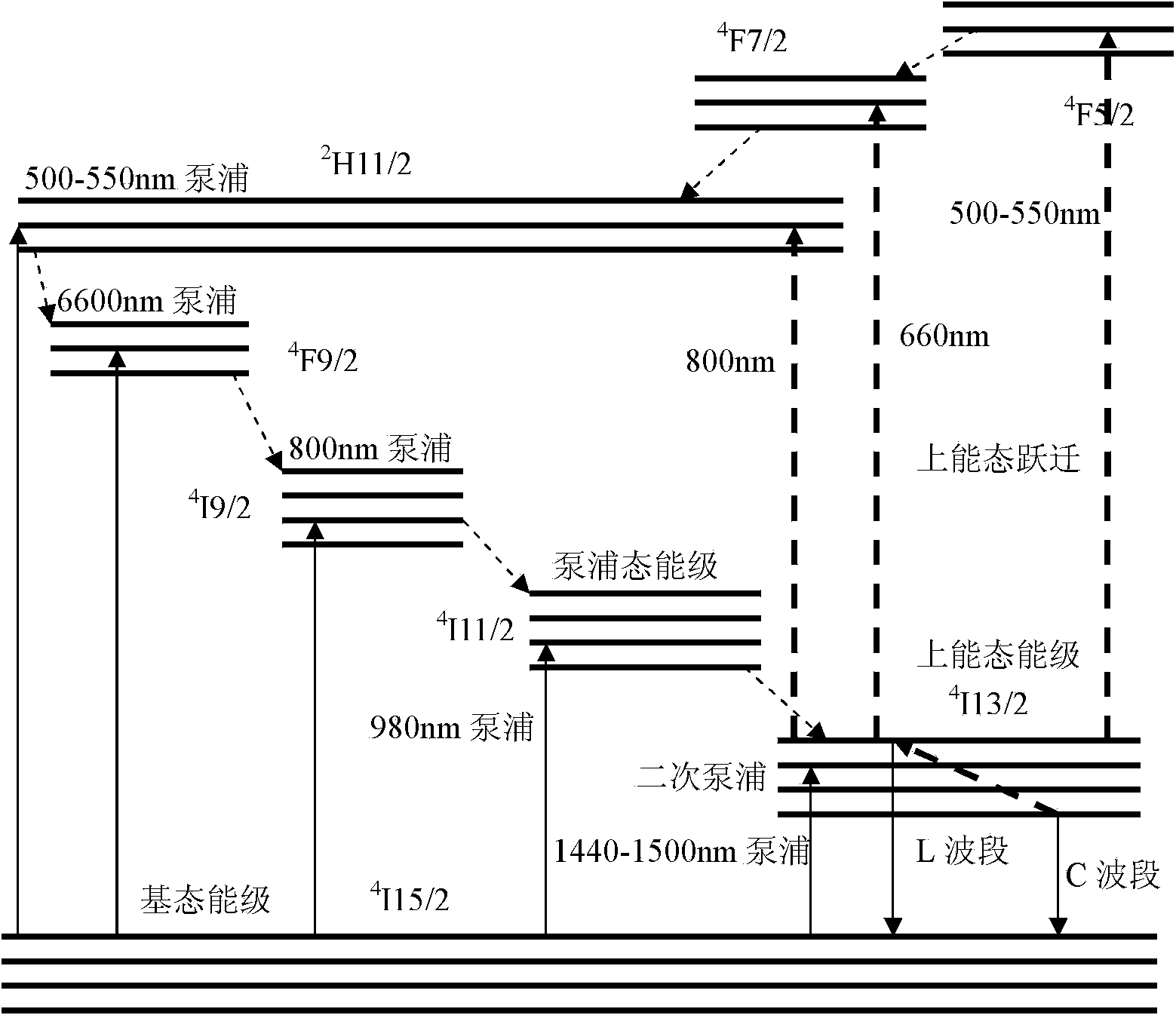

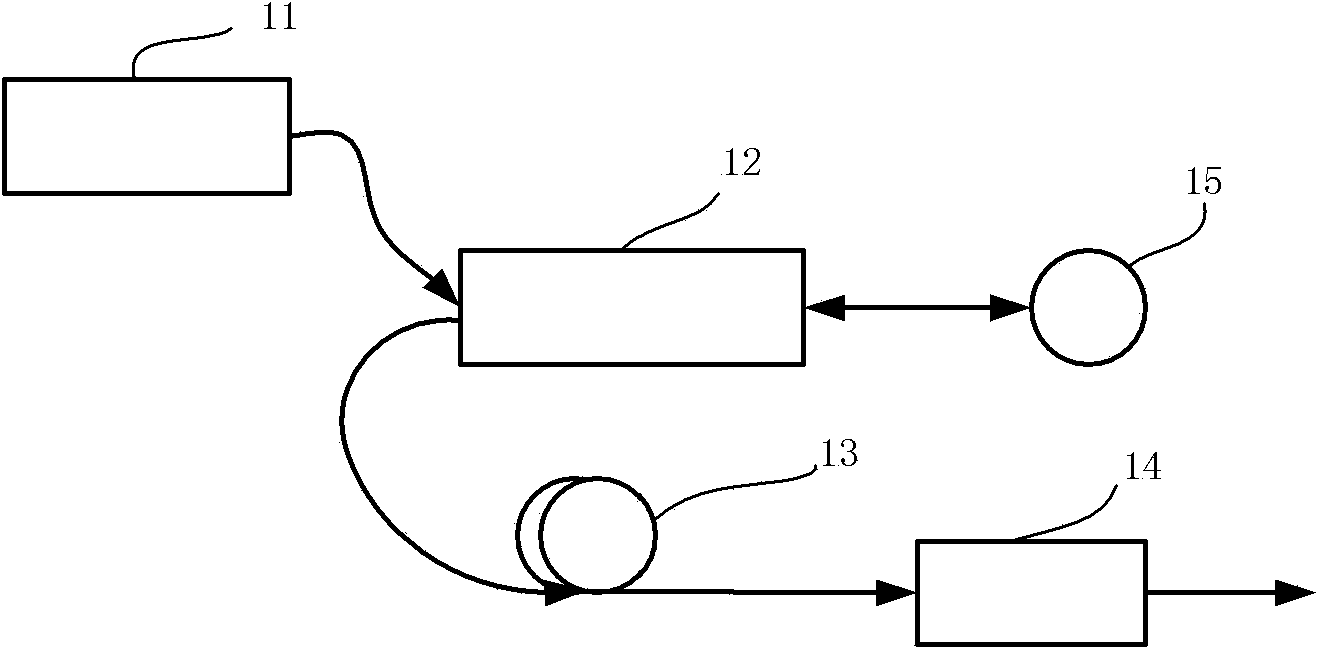

[0060] This embodiment specifically describes the implementation of the L-band light source of the present invention. Its structure diagram is as follows figure 2 shown. The 980nm pump laser output by the first pump laser is input through the 980nm first port of the first wavelength division multiplexer, and is output from the third port (980nm+1550nm) of the first wavelength division multiplexer and then passes through the broadband reflector , enter the second port (1550nm) of the first wavelength division multiplexer, and generate from 4 I 13/2 energy level to the ground state ( 4 I 15/2 ) energy level transition, as the length of the first erbium-doped fiber gradually increases, the generated fluorescence generates secondary pumping, and then transitions to 4 I 13/2 Under the action of the Stark effect, the fluorescence wavelength of the secondary transition shifts to the long wavelength direction, resulting in L-band fluorescence. A fiber isolator is connected aft...

Embodiment 2

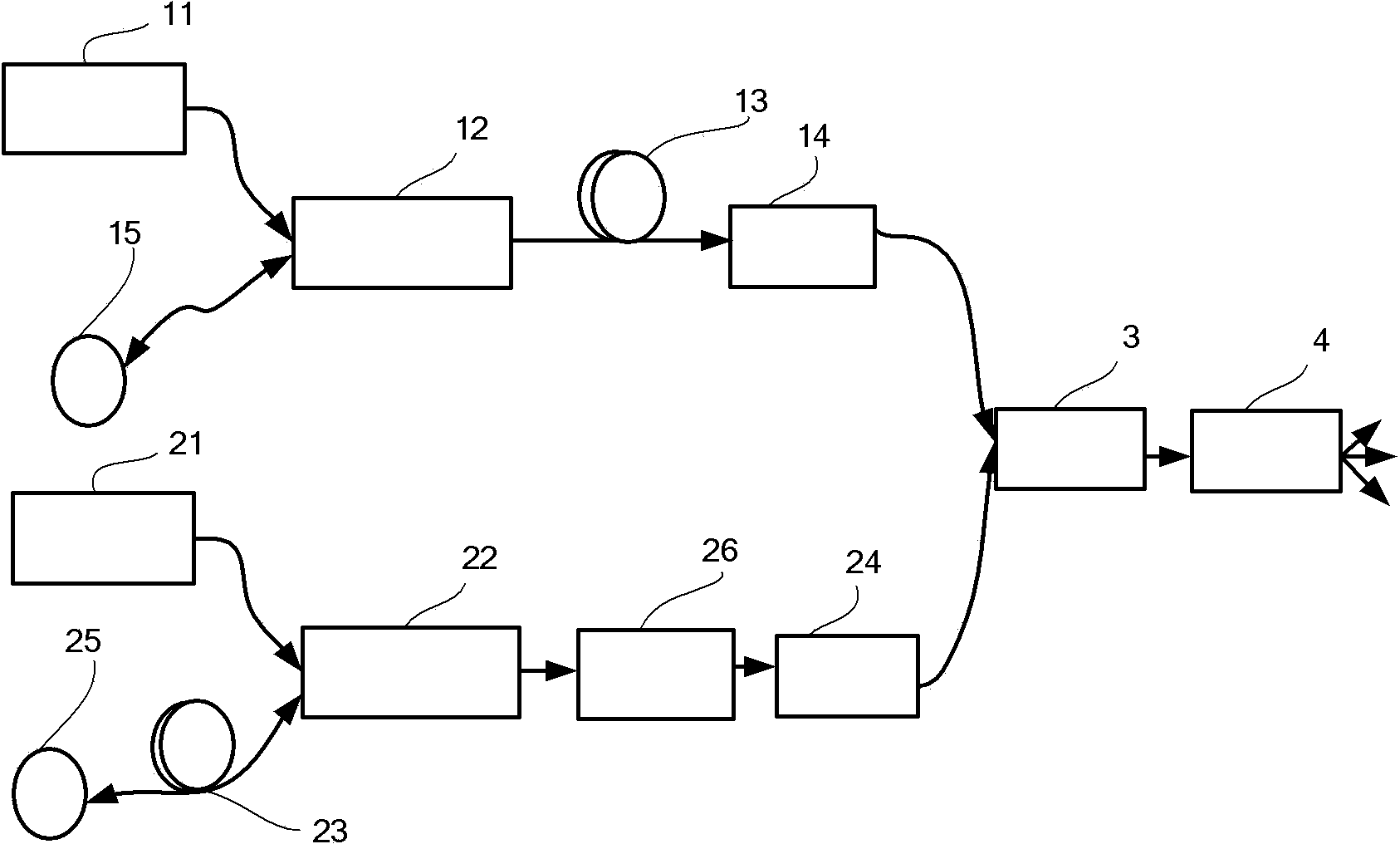

[0062] This embodiment specifically describes the implementation of the L+C band light source of the present invention. Its structure diagram is as follows image 3 shown. The C-band light source adopts a double-pass backward mode, and the 980nm pump laser output by the second pump laser is input through the first port (980nm) of the second wavelength division multiplexer, and is transmitted from the third port of the second wavelength division multiplexer After the port (980nm+1550nm) is output, it passes through the second erbium-doped fiber to generate fluorescence, and a fiber reflector is connected behind the second erbium-doped fiber. The unpumped 980nm light returns to the second erbium-doped fiber through the reflector and is pumped again. Improve the pumping efficiency, and the 1550nm fluorescence produced is output through the second port (1550nm) of the second wavelength division multiplexer to form a C-band spectrum. Since the gain coefficient and absorption coeff...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Light intensity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com