New technology for realizing cogeneration of industrial processes by utilization of thermoelectric material

A thermoelectric material, industrial process technology, applied in waste heat treatment, battery circuit devices, generators/motors, etc., can solve problems such as waste of electric energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

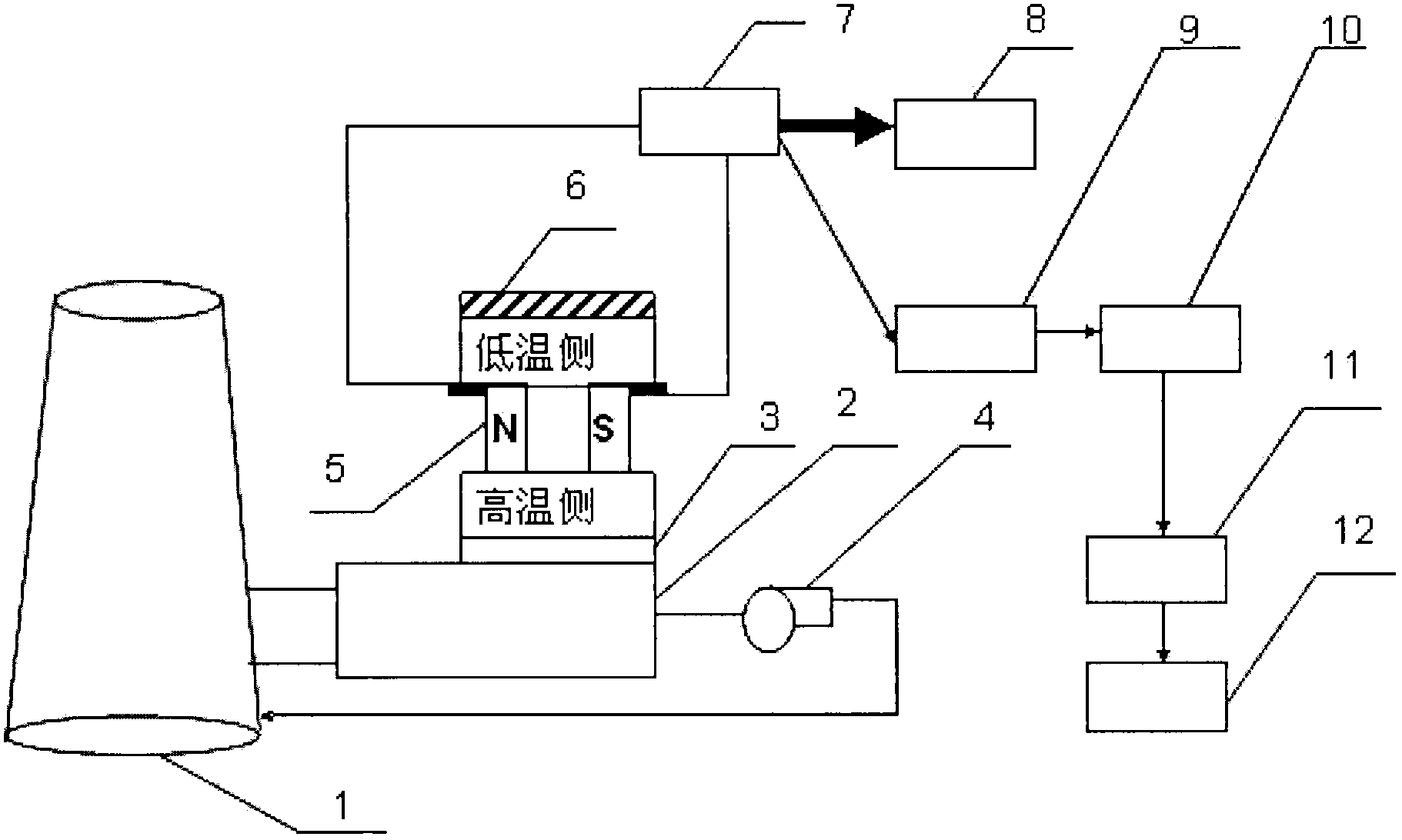

[0030] Example 1: Application in recovery of waste heat from low-temperature flue gas in heating furnace of iron and steel plant. The flue gas of the heating furnace is used as the heat source, and the flue gas is between 150 and 400°C. First, a suitable opening position must be selected on the flue, and the heat extractor should be reasonably designed so as not to affect the smoke exhaust capacity of the furnace. After passing through the heat extractor, it is sent into the flue through the induced draft fan. The thermoelectric material can be selected from the skutterudite series. The operating temperature range is between 300 and 650°C. The high temperature side (hot end) of the thermoelectric system can be made of copper, etc. The material with high thermal conductivity is arranged close to the wall of the flue pipe. The heat of the flue gas is directly transferred to the hot end of the thermoelectric system through the flue wall and the copper heat conduction plate, so tha...

Embodiment 2

[0031]Example 2: Application in recovery of high-temperature sensible heat of continuous casting slabs in iron and steel plants. The temperature of the continuous casting slab in the iron and steel plant is about 1000°C, and it will release a large amount of high-temperature radiant heat during transportation. The heat conduction plate in the heat conduction plate directly faces the continuous casting slab, and the radiant heat of the continuous casting slab is directly transmitted to the hot end of the thermoelectric power generation system through the heat conduction plate. It is necessary to carry out a special cooling design for the thermoelectric module in the thermoelectric power generation system to ensure that it is not affected by high temperature. and damaged. In thermoelectric power generation, the recommended material for the thermoelectric module is the oxide type, and the operating temperature is 250-1000°C. The use and power transmission of the thermoelectric po...

Embodiment 3

[0032] Embodiment 3: Application in the heat dissipation of the furnace wall of the recovery heating furnace. The heat dissipation temperature range of the furnace wall surface of the heating furnace is between 20°C and 100°C. The heat conduction plate in the heat taker should be arranged close to the furnace surface, the cooling end should be water-cooled, the material of the thermoelectric material should be BiTe series, and the temperature range is 0-300°C. The use of the thermoelectric system after power generation is the same as above. The electricity generated is limited, and it can be directly used as factory lighting without intervening in the new energy control system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com