Preparation method of closed water-based polyurethane modified PAE (polyarylether) wet strength agent

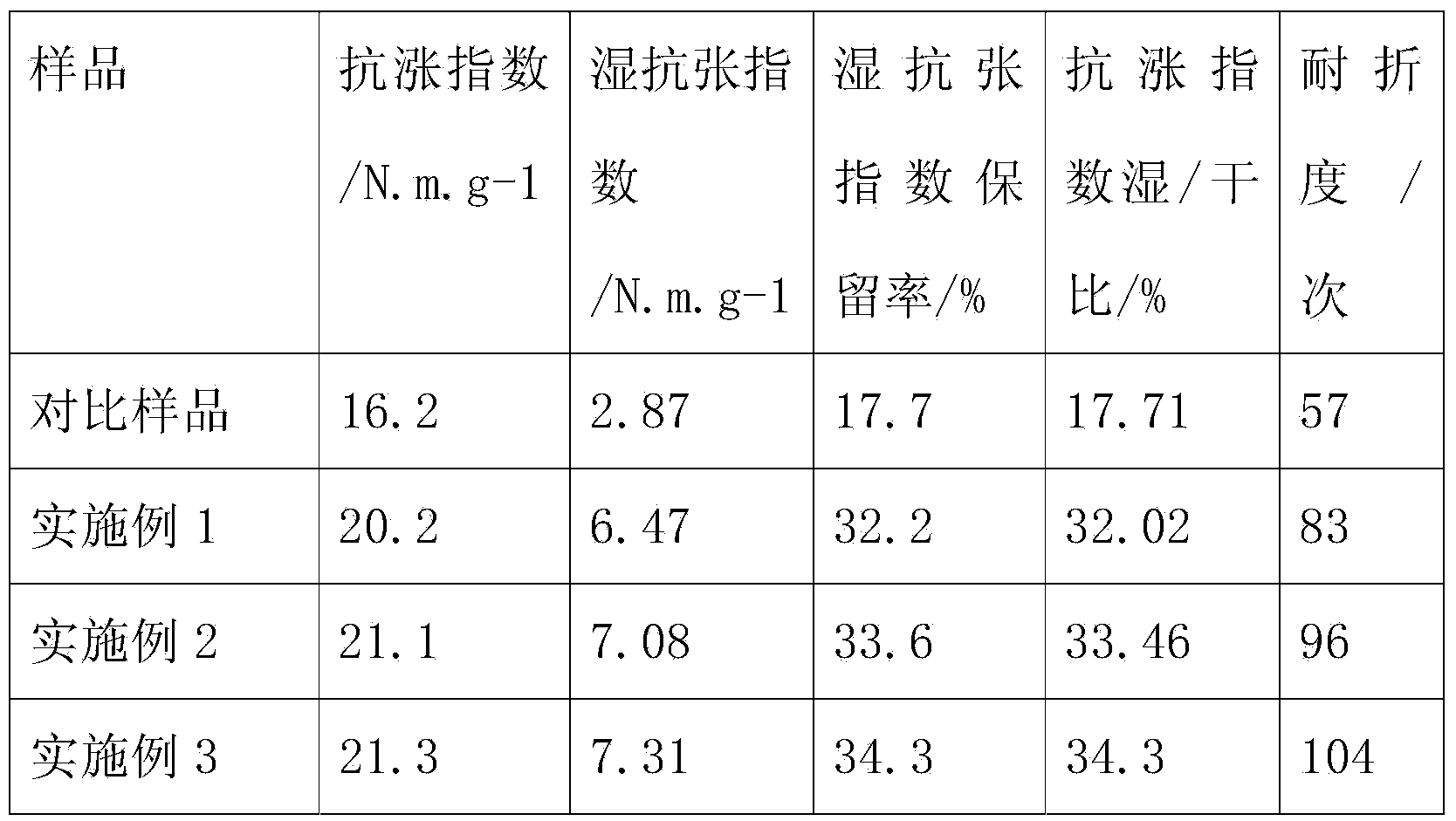

A technology of PAE wet strength agent and water-based polyurethane, which is applied in the direction of reinforcing agent addition, can solve the problems of limited use, and achieve the effects of increased folding resistance, increased wet strength retention rate, and good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Preparation of blocked polyurethane prepolymer: put 100g of polybutylene adipate diol (molecular weight: 1000) and 8g of 2,2'-dimethylol propionic acid into a stirring and heating device In a four-neck flask, after vacuum dehydration at 100°C for 1h, add 180g of dry N-methylpyrrolidone and 41.8g of toluene diisocyanate ([NCO] / [OH]=1.5) to react to its NCO at 80°C under the protection of nitrogen. The content reaches the theoretical value, and the polyurethane prepolymer with terminal NCO group is obtained. Then add 7g of methyl ethyl ketoxime and react at 80°C until its NCO content is zero to obtain a blocked polyurethane prepolymer;

[0030] (2), the preparation of PPC: in the four-neck flask that stirring, condensation tube are housed, add 103 grams of diethylenetriamine and 31 grams of deionized water, start stirring, slowly add 146 grams of adipic acid under stirring, make The temperature of the system should not exceed 130°C. Stir for 20 minutes after the addi...

Embodiment 2

[0033] (1) Put 100g of polytetrahydrofuran diol (molecular weight: 1000) and 9.4g of 2,2'-dimethylolpropionic acid into a four-necked flask with a stirring and heating device, dehydrate in vacuum at 100°C for 1 hour, then add 180g of dry N-methylpyrrolidone and 55g of diphenylmethane diisocyanate ([NCO] / [OH]=1.3) were reacted at 80°C under the protection of nitrogen until the NCO content reached the theoretical value to obtain NCO-terminated polyurethane prepolymer . Then add 4.5g of methyl ethyl ketoxime and react at 80°C until its NCO content is zero to obtain a blocked polyurethane prepolymer;

[0034] (2) Preparation of PPC: Add 108 grams of diethylenetriamine and 31 grams of deionized water into a four-necked flask equipped with a stirring and condenser tube, start stirring, and slowly add 146 grams of adipic acid under stirring to make the system The temperature should not exceed 130°C, stir for 20 minutes after the addition is complete, then heat to 180°C with a heatin...

Embodiment 3

[0037] (1) Put 100g of polyneopentyl glycol adipate diol (molecular weight: 2000) and 4.7g of 2,2'-dimethylolpropionic acid into a four-necked flask with a stirring and heating device. After vacuum dehydration at 100°C for 1 h, 170 g of N-methylpyrrolidone and 32 g of isophorone diisocyanate ([NCO] / [OH]=1.7) were added to react at 80°C under the protection of nitrogen until the NCO content reached the theoretical value. NCO based polyurethane prepolymer. Then add 5.2g of methyl ethyl ketoxime and react at 80°C until its NCO content is zero to obtain a blocked polyurethane prepolymer;

[0038](2) Preparation of PPC: Add 108 grams of diethylenetriamine and 31 grams of deionized water into a four-necked flask equipped with a stirring and condenser tube, start stirring, and slowly add 146 grams of adipic acid under stirring to make the system The temperature should not exceed 130°C, stir for 20 minutes after the addition is complete, then heat to 175°C with a heating mantle, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid content | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com