Dispersed copolymer of organic boron composite crosslinking agent and cationic polymer, preparation method and application thereof, and papermaking method

A technology of cationic polymer and composite cross-linking agent, applied in the field of papermaking, can solve the problems of unstable performance of retention and drainage aids, low wet tensile index of paper, and large environmental pollution, so as to improve retention and drainage. performance, improving wet tensile index, and the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The preparation method of the step b) organic boron composite cross-linking agent is as follows: add a solvent and an organic alcohol complexing agent into the reactor, then add a boron compound, and react at 80° C. for 3 to 5 hours by a one-pot method to obtain a transparent A viscous solution is obtained to obtain an organoboron solution; then a certain amount of polyvinyl alcohol is added to react for 1 hour to obtain an organoboron composite crosslinking agent.

[0043]In the step c), the first monomer is any one of diallylamine, triallylamine, N-methyldiallylamine or a mixture of two or more mixed in any ratio; the second The monomer is diallyl dimethyl ammonium chloride; the initiator is any one of ammonium persulfate-sodium bisulfite, sodium persulfate-sodium sulfite or potassium persulfate-sodium sulfite or a mixture of two or more in any ratio Mixture; pH regulator is glacial acetic acid.

[0044] The preparation method of the cationic polymer in the step c) i...

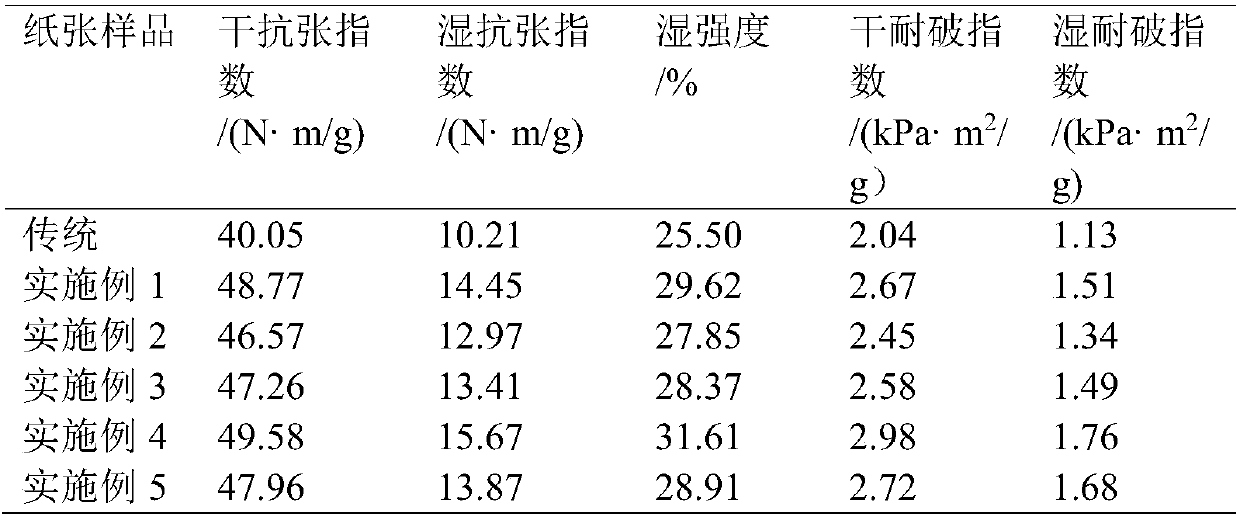

Embodiment 1

[0048] In the cellulose pulp, add 1% (based on the quality of the dry fiber) of the reinforcing agent PAE and 0.1% (based on the quality of the reinforcing agent) of the filler coagulant polyacrylamide. Add 0.5% (based on the quality of dry fiber) of organic boron composite cross-linking agent into the slurry, wherein the organic boron composite cross-linking agent is polymerized from the following raw materials: 15 parts of sodium tetraborate, 60 parts of organic alcohol coordination Agent ethylene glycol, 25 parts of solvent glycerin, 1 part of polyvinyl alcohol. Then, 0.25% (based on the quality of the dry fiber) of cationic polymer is added to the slurry, wherein the cationic polymer is polymerized from the following monomers: 50 parts of the first monomer diallylamine, 10 parts of the second monomer Two monomer diallyl dimethyl ammonium chloride, 3 parts of pH adjuster, 0.01 part of initiator ammonium persulfate-sodium bisulfite, 30 parts of deionized water. Finally, the...

Embodiment 2

[0052] In the cellulose pulp, add 1% (based on the quality of the dry fiber) of the reinforcing agent PAE and 0.1% (based on the quality of the reinforcing agent) of the filler coagulant polyacrylamide. 3% (based on the quality of the dry fiber) of the organic boron composite crosslinking agent is added to the slurry, wherein the organic boron composite crosslinking agent is polymerized from the following raw materials: 25 parts of sodium tetraborate, 50 parts of organic alcohol coordination Agent ethylene glycol, 25 parts of solvent glycerin, 3 parts of polyvinyl alcohol. Then, 2% (based on the mass of dry fiber) cationic polymer is added to the slurry, wherein the cationic polymer is polymerized from the following monomers: 20 parts of the first monomer diallylamine, 40 parts of the second monomer Two monomer diallyl dimethyl ammonium chloride, 2.5 parts of pH adjuster, 0.01 part of initiator ammonium persulfate-sodium bisulfite, 40 parts of deionized water. Finally, the pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com