Preparation method of europium-doped hydroxyapatite (HAP) fluorescent nanoparticles

A hydroxyapatite and fluorescent nanotechnology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of excessive grain growth and limited improvement of the latter, and achieve the effect of improving crystallinity and fluorescence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

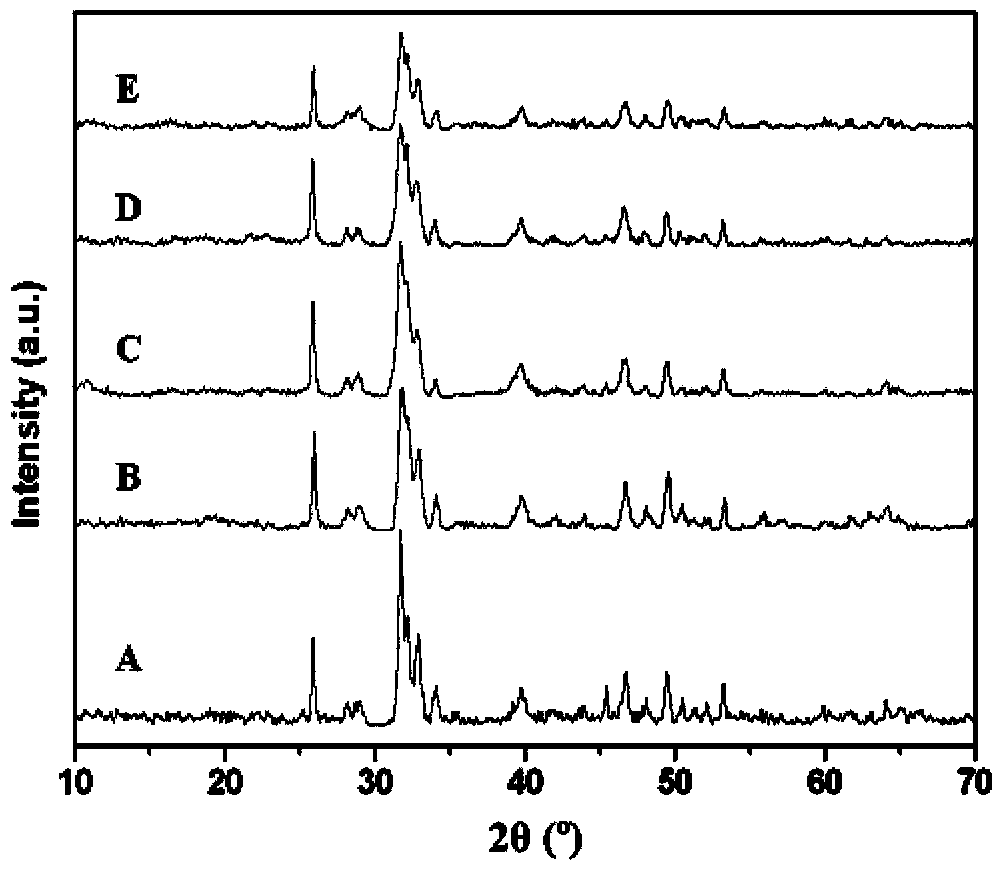

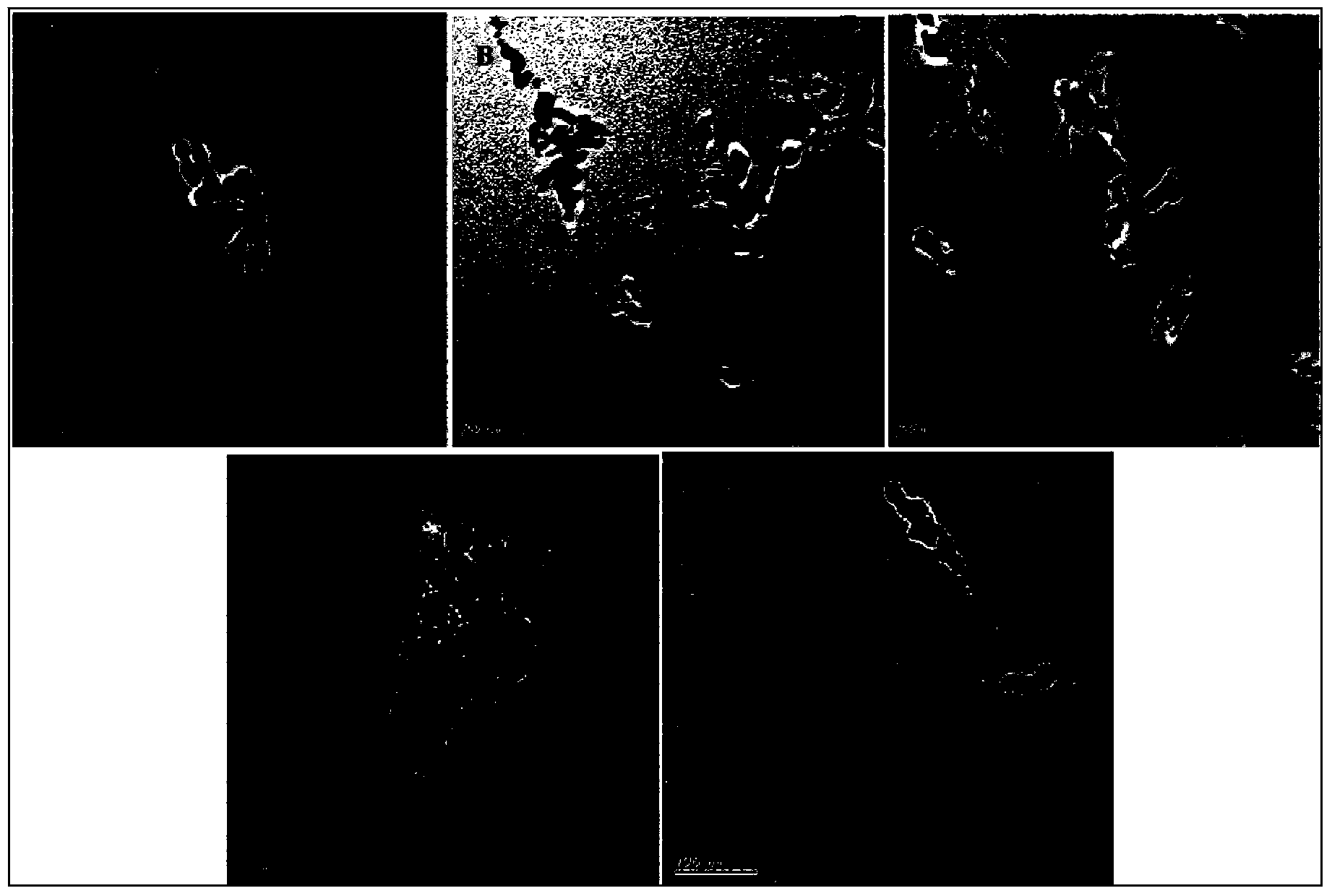

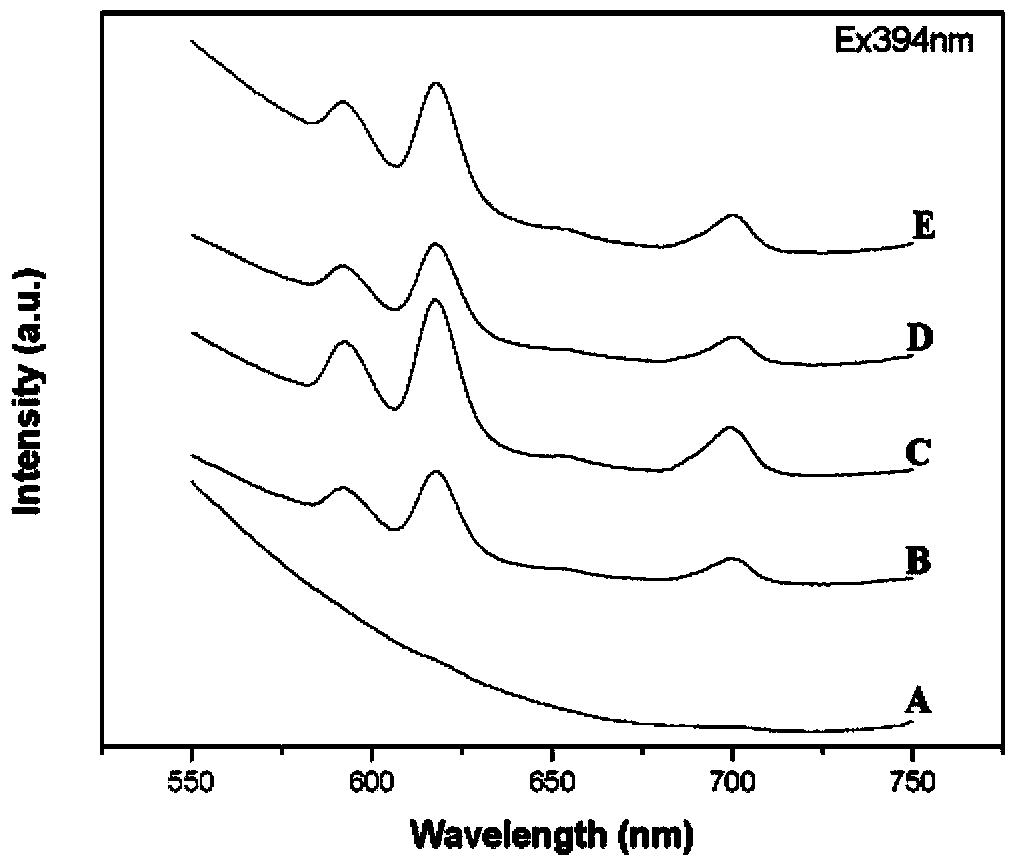

Embodiment 1

[0022] First, configure a mixed aqueous solution of calcium chloride and europium chloride to control Ca 2+ and Eu 3+ The total concentration of is 0.0334mol / L, and the Eu / (Ca+Eu) molar ratio is 0.1%. Configure disodium hydrogen phosphate aqueous solution, PO 4 3- The concentration is 0.02mol / L. According to the molar ratio (Ca+Eu) / P=1.67, quickly pour 100mL disodium hydrogen phosphate aqueous solution into 100mL calcium chloride and europium chloride mixed aqueous solution at room temperature, stir and mix evenly, react for 15 minutes, and centrifuge to obtain a precipitate The mixture was washed three times with deionized water and redispersed in 200 mL of deionized water. Then, the stabilizer polysaccharide sodium heparin (concentration: 0.6 mg / mL) was added, and the high-energy ultrasonic probe was ultrasonically dispersed for 6 minutes to obtain a stable suspension. Finally, a hydrothermal treatment was carried out at 121° C. for 1 hour in an autoclave to obtain a st...

Embodiment 2

[0024] First, configure a mixed aqueous solution of calcium chloride and europium chloride to control Ca 2+ and Eu 3+ The total concentration of is 0.0334mol / L, and the Eu / (Ca+Eu) molar ratio is 2%. Configure disodium hydrogen phosphate aqueous solution, PO 4 3-The concentration is 0.02mol / L. According to the molar ratio (Ca+Eu) / P=1.67, quickly pour 100mL disodium hydrogen phosphate aqueous solution into 100mL calcium chloride and europium chloride mixed aqueous solution at room temperature, stir and mix evenly, react for 15 minutes, and centrifuge to obtain a precipitate The mixture was washed three times with deionized water and redispersed in 200 mL of deionized water. Then, the stabilizer polysaccharide sodium heparin (concentration: 0.6 mg / mL) was added, and the high-energy ultrasonic probe was ultrasonically dispersed for 6 minutes to obtain a stable suspension. Finally, a hydrothermal treatment was carried out at 121° C. for 1 hour in an autoclave to obtain a stabl...

Embodiment 3

[0026] First, configure a mixed aqueous solution of calcium chloride and europium chloride to control Ca 2+ and Eu 3+ The total concentration of is 0.0334mol / L, and the Eu / (Ca+Eu) molar ratio is 4%. Configure disodium hydrogen phosphate aqueous solution, PO 4 3- The concentration is 0.02mol / L. According to the molar ratio (Ca+Eu) / P=1.67, quickly pour 100mL disodium hydrogen phosphate aqueous solution into 100mL calcium chloride and europium chloride mixed aqueous solution at room temperature, stir and mix evenly, react for 15 minutes, and centrifuge to obtain a precipitate The mixture was washed three times with deionized water and redispersed in 200 mL of deionized water. Then, the stabilizer polysaccharide sodium heparin (concentration: 0.6 mg / mL) was added, and the high-energy ultrasonic probe was ultrasonically dispersed for 6 minutes to obtain a stable suspension. Finally, a hydrothermal treatment was carried out at 121° C. for 1 hour in an autoclave to obtain a stab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com