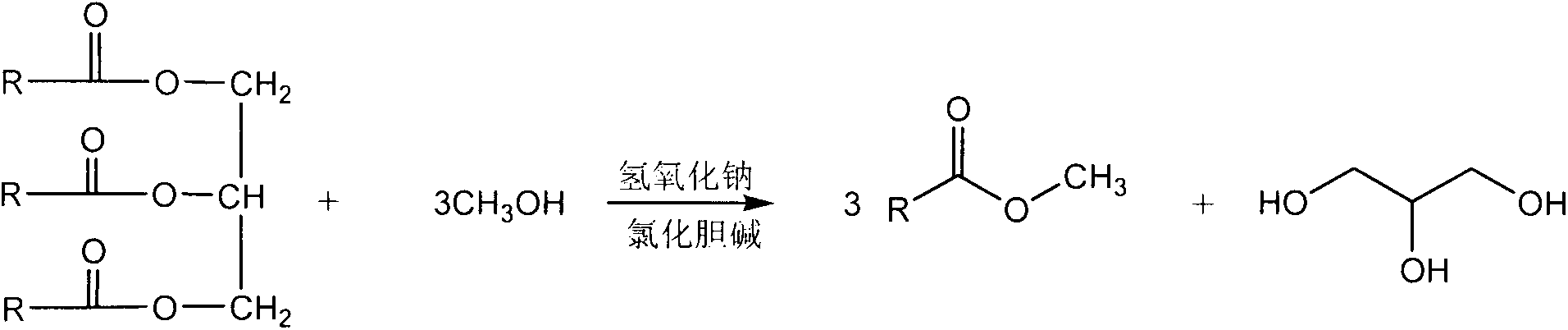

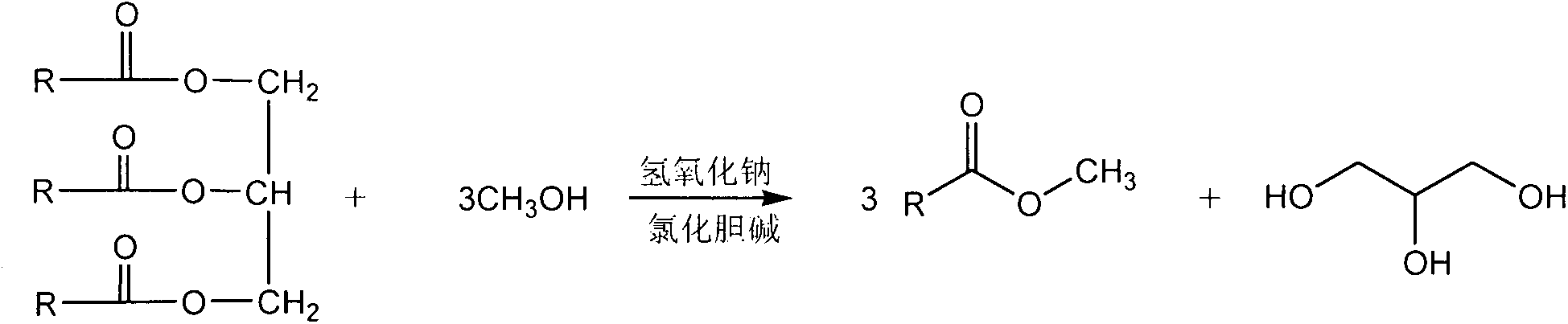

Method for preparing biodiesel through inducing eutectic system on site

A biodiesel and eutectic technology, applied in biofuel, petroleum industry, liquid carbon-containing fuel, etc., can solve the problems of strong corrosiveness of the catalyst, difficult separation and recovery, and easy saponification of the product, so as to achieve easy recycling and low cost The effect of low cost and simplified process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] In a 100mL three-neck round bottom flask, add 30g (0.034mol) soybean oil (average molecular weight 878.25) and preheat it in a water bath at 65°C, then add 0.3g (0.0075mol) NaOH, 6g methanol (0.1875mol), 0.6g chlorine Choline, stirred and refluxed for 4.0 hours at normal pressure in a water bath at 65°C, cooled to room temperature, transferred to a separatory funnel for liquid-liquid phase separation, the upper layer was the product, washed with hot water for 3 to 5 times, Vacuum drying at 400 Pa and 80°C yielded 25.7 g of pure product with a yield of about 85%. The unreacted raw material, catalyst, and eutectic mixture in the lower layer can be directly used in the next batch of reactions without treatment.

Embodiment 2

[0021] In a 100mL three-necked round-bottomed flask, add 30g (0.034mol) soybean oil (average molecular weight 878.25) and preheat it in a water bath at 65°C, then add 0.15g of NaOH, 10.9g of methanol (0.34mol), and 3.0g of choline chloride Alkali, stirred and refluxed in a water bath at 65°C under normal pressure for 2.0 hours, cooled to room temperature, transferred to a separatory funnel for liquid-liquid phase separation, and the upper layer was the product. After washing with hot water for 3 to 5 times, Vacuum drying at 80°C gave 26.0 g of the pure product, with a yield of about 86%; the unreacted raw material, catalyst, and eutectic mixture in the lower layer could be directly used in the next batch of reactions without treatment.

Embodiment 3

[0023] In a 100mL three-neck round bottom flask, add 30g of soybean oil (average molecular weight 878.25) and preheat it in a water bath at 65°C, then add 1.5g of NaOH, 8g of methanol, and 1.0g of choline chloride. Stir and reflux for 3.0 hours, cool to room temperature, transfer to a separatory funnel for liquid-liquid phase separation, and the upper layer is the product. After washing with hot water for 3 to 5 times, vacuum dry at 400Pa and 80°C to obtain the pure product 26.6 g, the yield is about 88%; the mixture of unreacted raw materials, catalysts and eutectic systems in the lower layer can be directly used in the next batch of reactions without treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com