Bubble guide component, high-density microorganism culture device and applications

A technology of microbial cultivation and bubble generation device, which is applied in the field of microbial cultivation, can solve the problems of unable to enlarge the mode of microbial incubator, increase energy consumption in the microbial cultivation process, limit the application of microbial incubator, etc., achieve flexible design and assembly methods, improve The effect of material and energy utilization efficiency and reduction of cultivation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

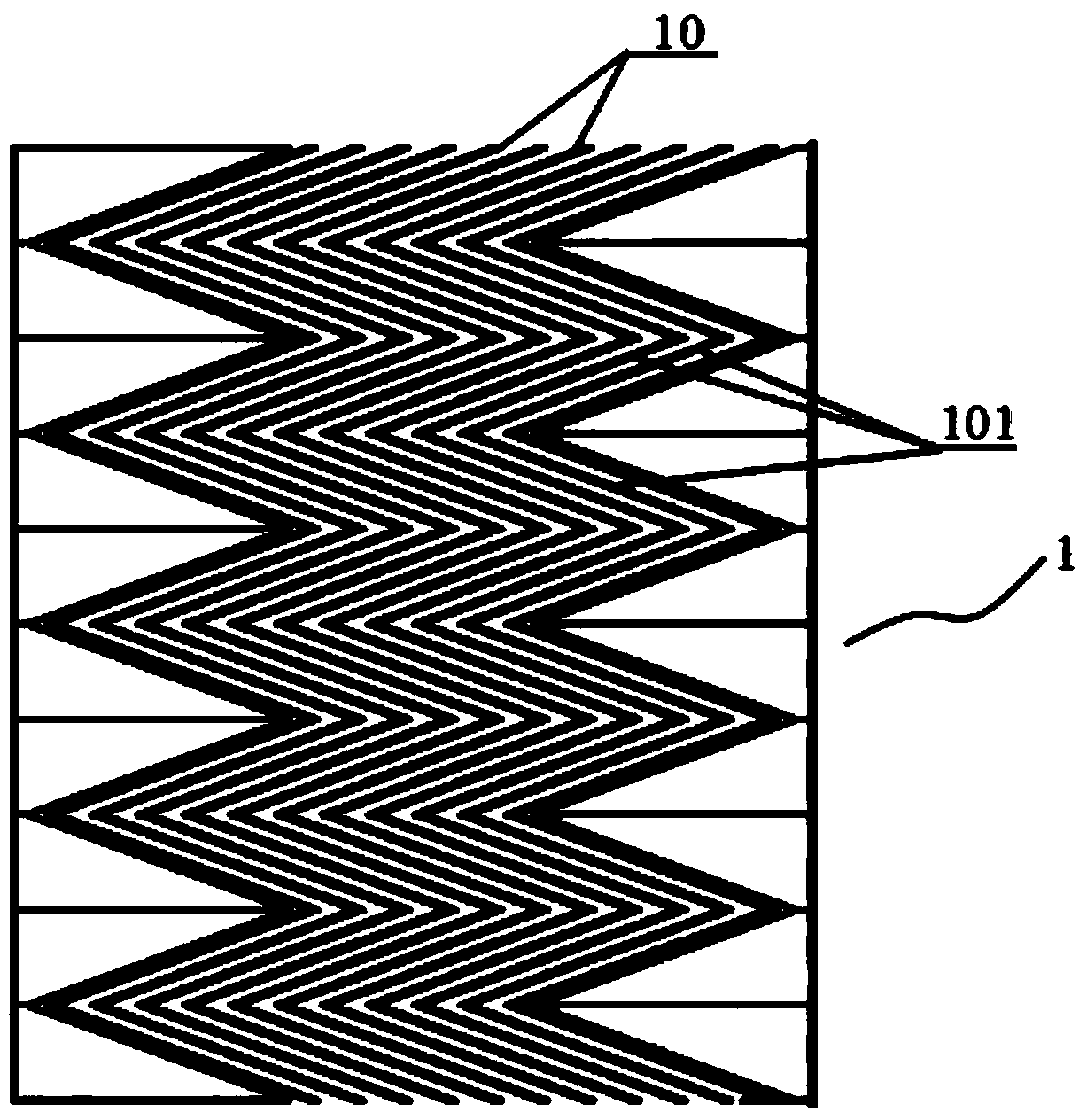

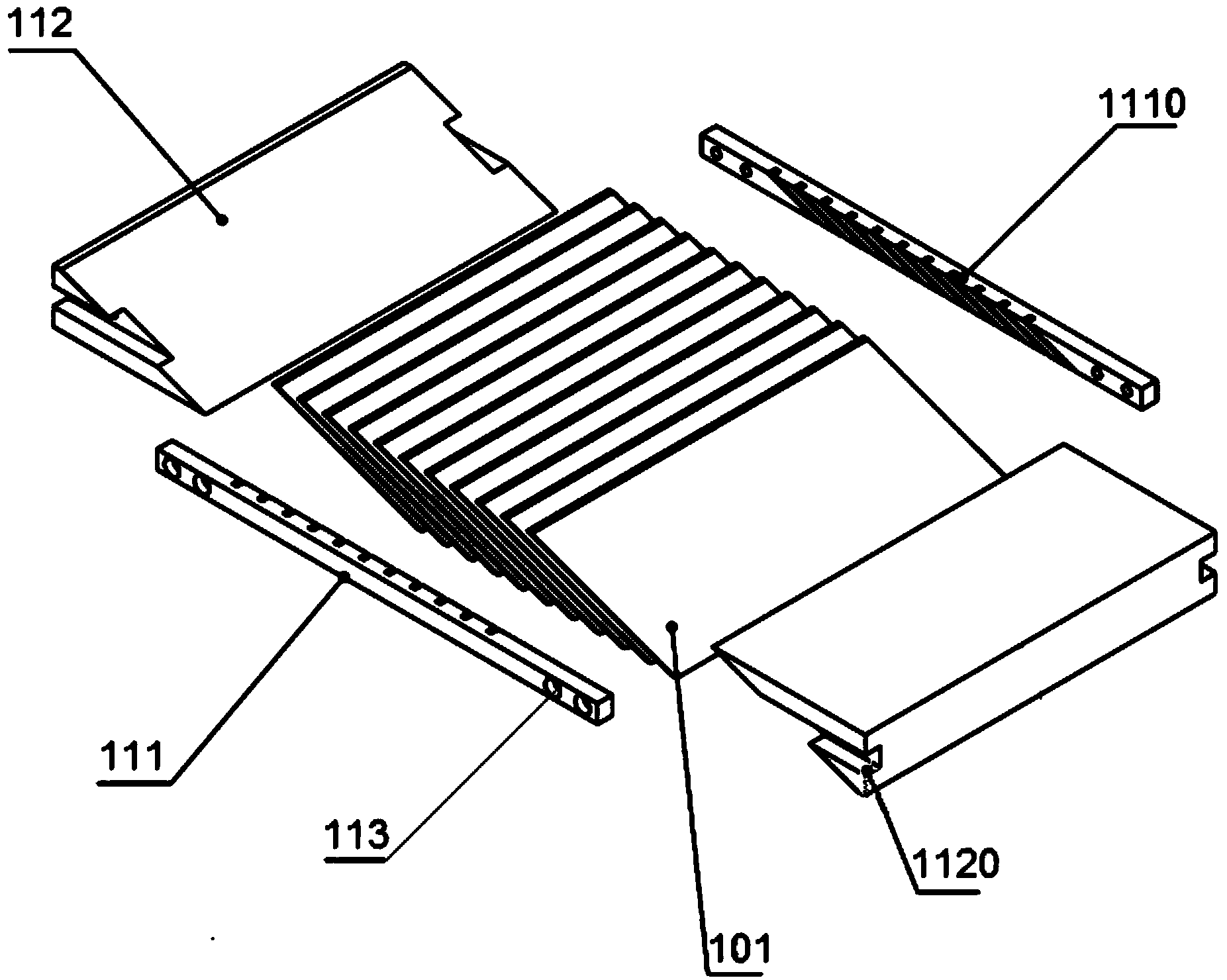

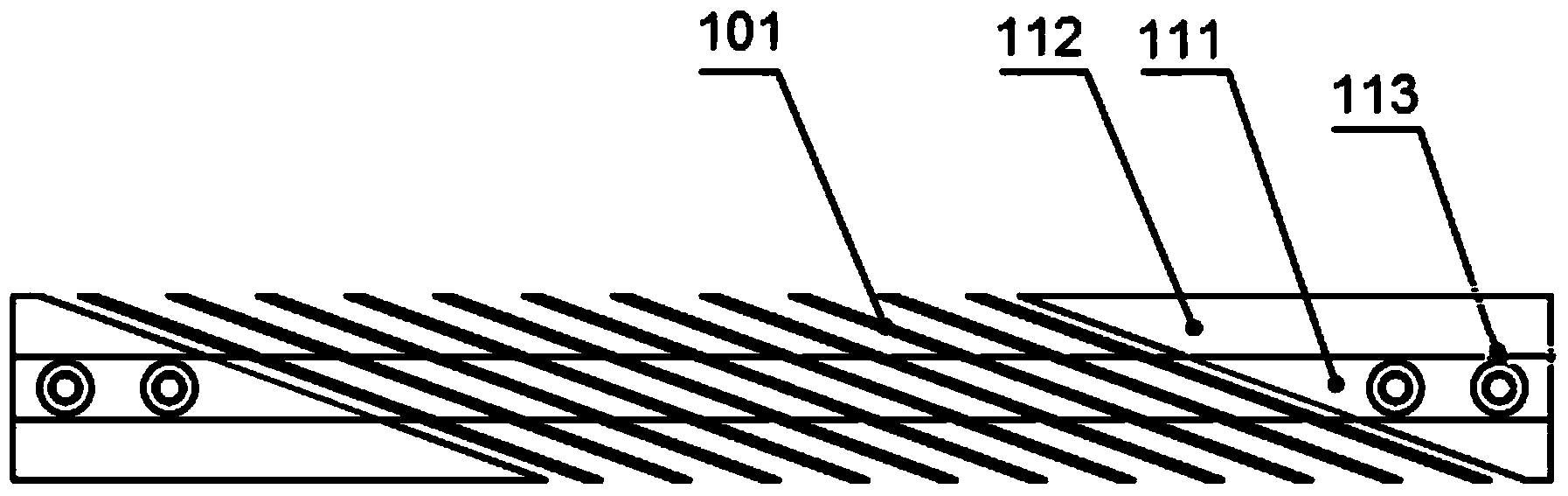

[0031] Figure 1 to Figure 5 A preferred embodiment is given to facilitate the mass production of guide plates and the assembly of air bubble guide components. Such as figure 1 As shown, it is a structural schematic diagram of the air bubble guide assembly. The air bubble guide assembly 1 includes a plurality of meandering guide members 10 arranged at equal intervals along the horizontal direction. The guide plate 101 is inclined relative to the horizontal plane, and the inclination direction of any adjacent guide plate 101 relative to the horizontal plane in the same zigzag guide member 10 is opposite, and a zigzag rising channel is formed between any adjacent zigzag guide members 10, and the zigzag guide member 10 Any guide plate 101 overlaps with the projection of the closest guide plate 101 on the horizontal plane of the adjacent zigzag g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com