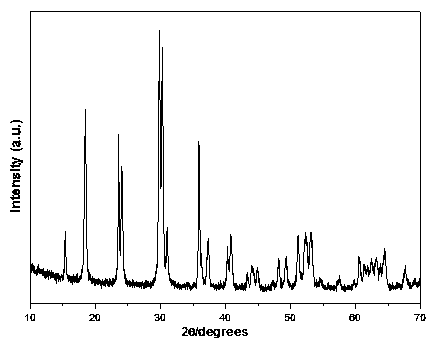

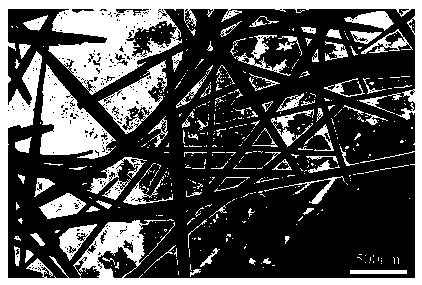

Method of preparing cadmium tungstate nanowire by microwave method

A cadmium tungstate and nanowire technology, which is applied in the field of preparation of cadmium tungstate nanowires, can solve the problem that the luminescence performance and damage resistance of the cadmium tungstate nanowire are reduced, the aspect ratio of the cadmium tungstate nanowire is small, and the User requirements and other issues, to achieve the effect of easy industrial production, low cost, environmental protection industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Step 1 Make sodium tungstate into a solution and adjust the WO in the solution 4 2- The ion concentration is 0.05mol / L;

[0023] Step 2: Make cadmium chloride into a solution and adjust the Cd in the solution 2+ The ion concentration is 0.05mol / L;

[0024] Step 3 mixes the sodium tungstate aqueous solution prepared in step 1 with the cadmium chloride aqueous solution prepared in step 2, wherein the molar ratio of sodium tungstate and cadmium chloride is 1:1, and after stirring the obtained solution for 10 minutes, carry out suction filtration;

[0025] Step 4 Place the precipitate obtained in Step 3 in a corundum crucible, and then place the corundum crucible in a container containing carbon powder, so that the carbon powder surrounds the corundum crucible, cover the lid, and move the container into a microwave oven;

[0026] Step 5 The power of the microwave oven is 160W, and react for 90 minutes under the action of microwave;

[0027] Step 6 After the reaction is...

Embodiment 2

[0030] Step 1 Make sodium tungstate into a solution and adjust the WO in the solution 4 2- The ion concentration is 1.2mol / L;

[0031] Step 2: Make cadmium chloride into a solution and adjust the Cd in the solution 2+ The ion concentration is 1.2mol / L;

[0032] Step 3 mixes the sodium tungstate aqueous solution prepared in step 1 with the cadmium chloride aqueous solution prepared in step 2, wherein the molar ratio of sodium tungstate and cadmium chloride is 1:1, and after stirring the obtained solution for 20 minutes, carry out suction filtration;

[0033] Step 4 Place the precipitate obtained in Step 3 in a corundum crucible, and then place the corundum crucible in a container containing carbon powder, so that the carbon powder surrounds the corundum crucible, cover the lid, and move the container into a microwave oven;

[0034] Step 5 The power of the microwave oven is 500W, and react for 50 minutes under the action of microwave;

[0035] Step 6 After the reaction is o...

Embodiment 3

[0037] Step 1 Make sodium tungstate into a solution and adjust the WO in the solution 4 2- The ion concentration is 2mol / L;

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com