Hemispherical resonance micro mechanical gyroscope and processing technology thereof

A mechanical gyro and hemispherical resonance technology, applied in gyroscope/steering sensing equipment, metal material coating technology, gyro effect for speed measurement, etc., can solve the problems of not being widely used, high cost, and difficult processing, etc. Achieve small size, high precision, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

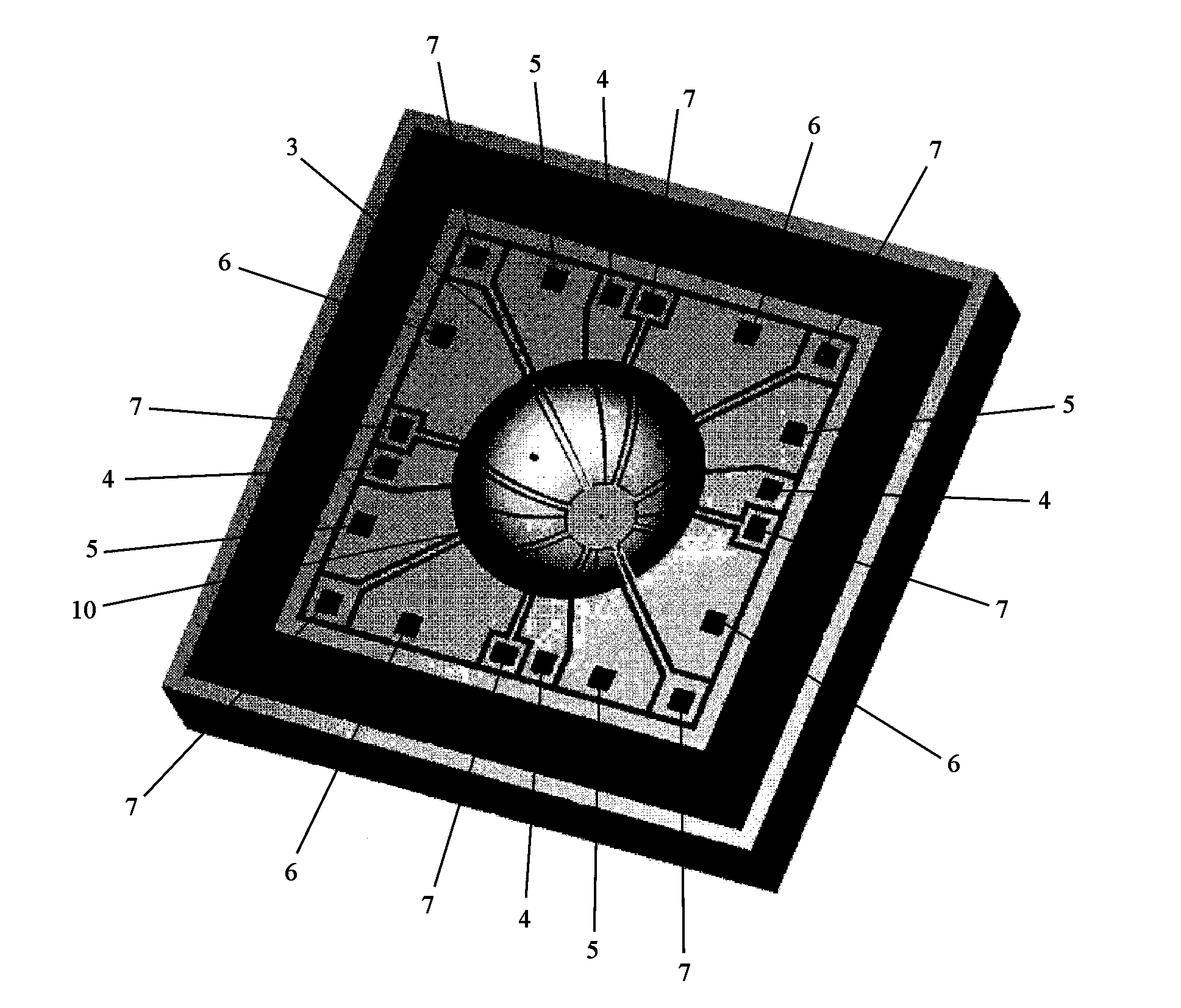

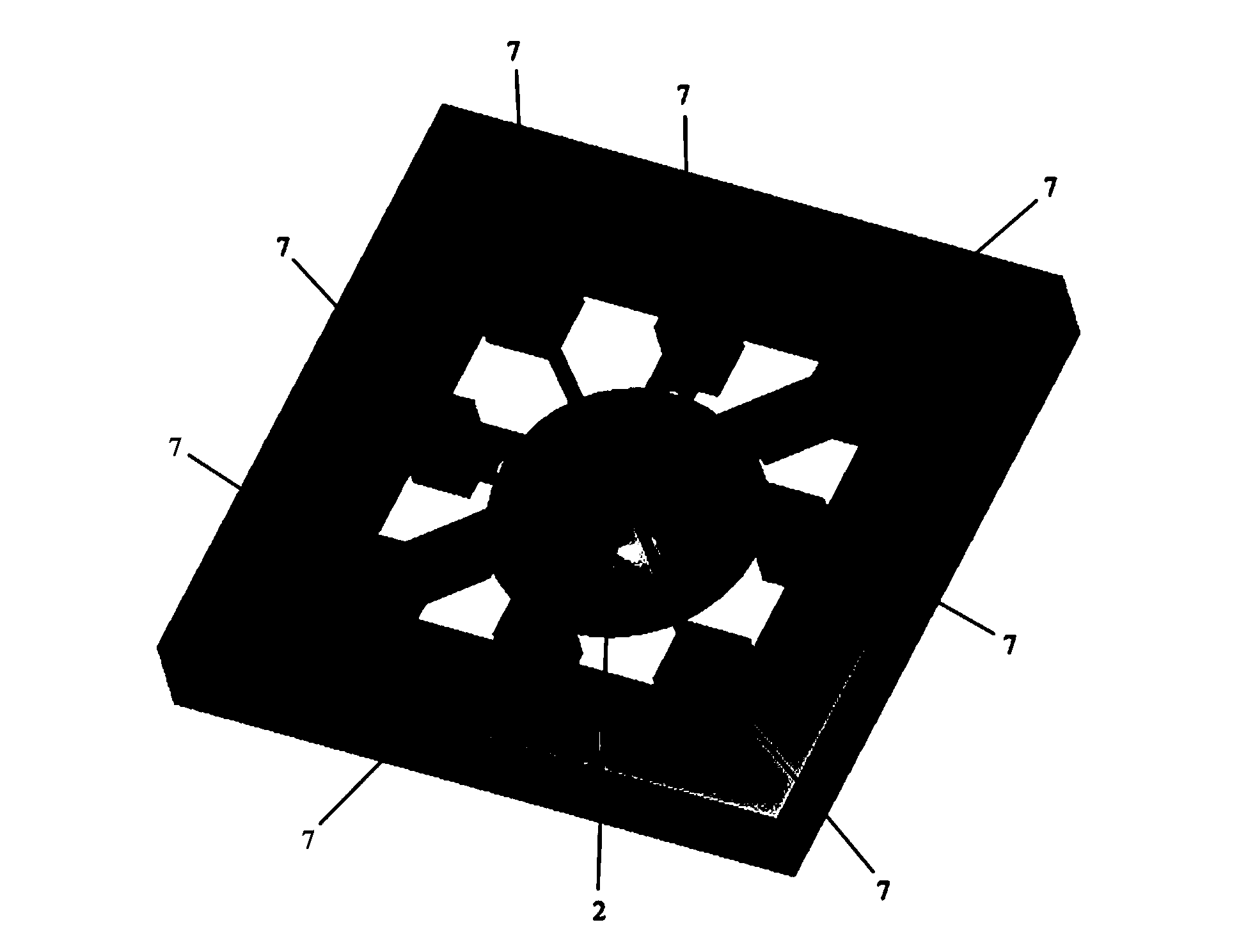

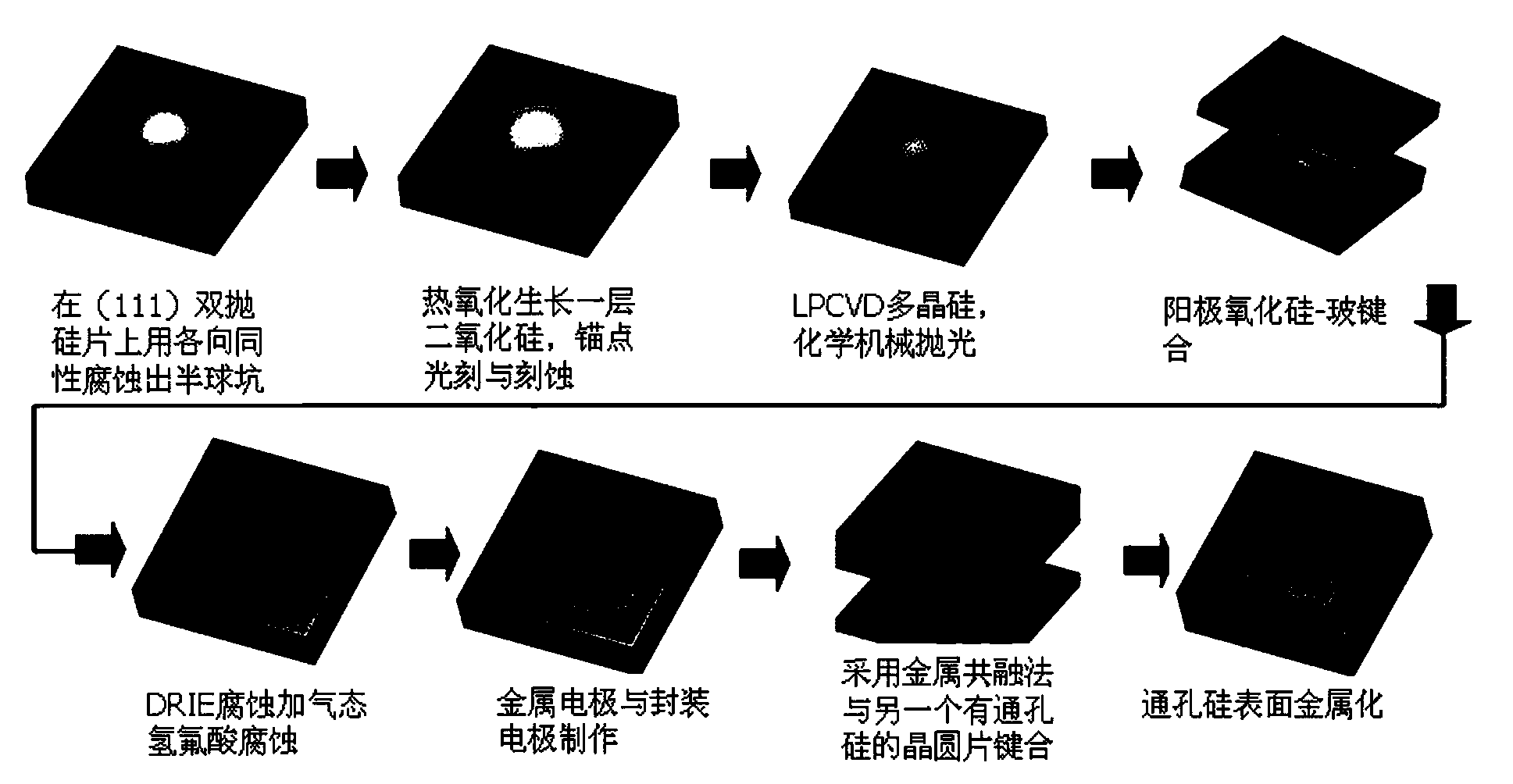

[0041] Embodiment 1: A hemispherical resonant micromachined gyroscope, which includes a resonant layer 1 , a first capping layer 9 and a second capping layer respectively bonded to both sides of the resonant layer 1 . See attached figure 1 And attached figure 2 shown.

[0042] The resonant layer 1 includes a hemispherical shell 2 and a plurality of silicon spherical electrodes arranged around the hemispherical shell 2 . The hemispherical shell 2 is made of polysilicon, silicon dioxide, silicon nitride or diamond, and in this embodiment, polysilicon is selected. The silicon spherical electrode is formed by etching multiple deep grooves 3 on the silicon wafer, and its material is highly doped single crystal silicon. The number of silicon spherical electrodes is 20 or 24, which include drive electrodes 4 , force balance electrodes 5 , signal detection electrodes 6 , and shield electrodes 7 . In this embodiment, there are 8 shielding electrodes 7, which are evenly distributed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Resonant frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com