Preparation method for cobalt-nickel oxide composite material as supercapacitor electrode material

A technology of cobalt-nickel oxide and supercapacitors, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors, etc., can solve problems such as easy to cause danger, achieve cheap prices, increase specific capacitance, and good electrochemical stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Weigh 2.5mmo1 nickel acetate tetrahydrate (C 4 h 6 NiO 4 4H 2 O) and 2.5mmol cobalt acetate tetrahydrate (C 4 h 6 CoO 4 4H 2 O) Dissolve in a mixed solution of 10mL ethylene glycol and 36mL water, stir for 20 minutes, nickel acetate is completely dissolved, then add 0.005g glucose, and continue stirring for 10 minutes to obtain a mixed solution:

[0029] (2) Pour the above mixed solution into a polytetrafluoroethylene hydrothermal reaction kettle, keep the filling degree of 80%, put the hydrothermal reaction kettle into a blast drying oven, react at 180°C for 16 hours, and then cool the reaction Kettle to room temperature.

[0030] (3) Centrifuge the obtained product, wash with deionized water and ethanol respectively, and dry; put the dried sample into a muffle furnace and calcinate at 450°C for 2 hours; the final sample obtained is a supercapacitor cobalt-nickel oxide electrode material.

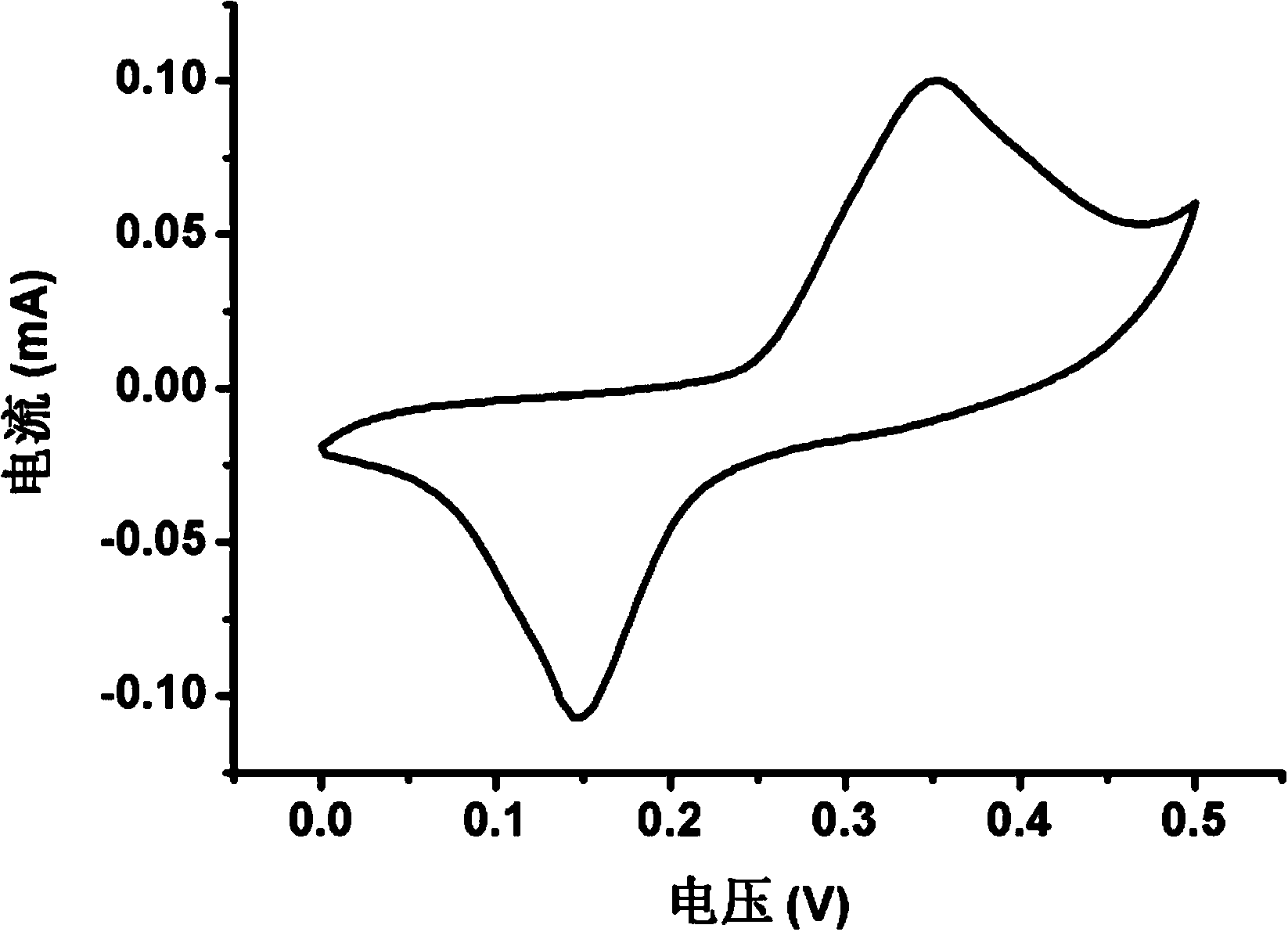

[0031] The SEM figure of the cobalt-nickel oxide composite materia...

Embodiment 2

[0034] (1) Take by weighing 3mmol nickel acetate tetrahydrate (C 4 h 6 NiO 4 4H 2 O) and 4mmol cobalt acetate tetrahydrate (C 4 h 6 CoO 4 4H 2 O) be dissolved in the mixed solution that 23mL ethylene glycol and 23mL water form, stir 10 minutes, nickel acetate dissolves completely, then add 0.010g glucose, continue to stir for 20 minutes again, make mixed solution;

[0035] (2) Pour the above mixed solution into a polytetrafluoroethylene hydrothermal reaction kettle, keep the filling degree of 80%, put the hydrothermal reaction kettle into a blast drying oven, react at 160°C for 24 hours, and then cool the reaction Kettle to room temperature.

[0036] (3) Centrifuge the obtained product, wash with deionized water and ethanol respectively, and dry; put the dried sample into a muffle furnace and calcinate at 450°C for 1 hour; the final sample obtained is supercapacitor cobalt-nickel oxide electrode material.

Embodiment 3

[0038] (1) Weigh 2mmol nickel acetate tetrahydrate (C4 h 6 NiO 4 4H 2 O) and 3 mmol cobalt acetate tetrahydrate (C 4 h 6 CoO 4 4H 2 O) be dissolved in the mixed solution that 30mL ethylene glycol and 16mL water form, stir 30 minutes, nickel acetate dissolves completely, then add 0.005g glucose, continue to stir for 20 minutes again, make mixed solution;

[0039] (2) Pour the above mixed solution into the polytetrafluoroethylene hydrothermal reaction kettle, keep the filling degree of 80%, put the hydrothermal reaction kettle into the blast drying oven, react at 180°C for 12 hours, then cool the reaction Kettle to room temperature.

[0040] (3) Centrifuge the obtained product, wash with deionized water and ethanol respectively, and dry; put the dried sample into a muffle furnace and calcinate at 450°C for 3 hours; the final sample obtained is supercapacitor cobalt-nickel oxide electrode material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com