Electrolytic solution for high-temperature high-magnification type lithium ion battery

A lithium-ion battery, electrolyte technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problem of high resistance value of SEI film, and achieve the effect of excellent cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

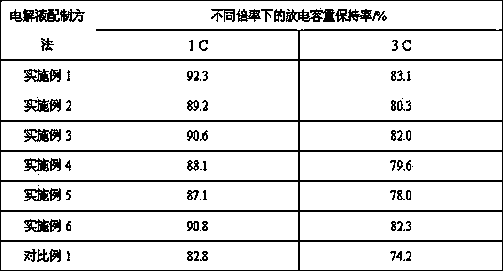

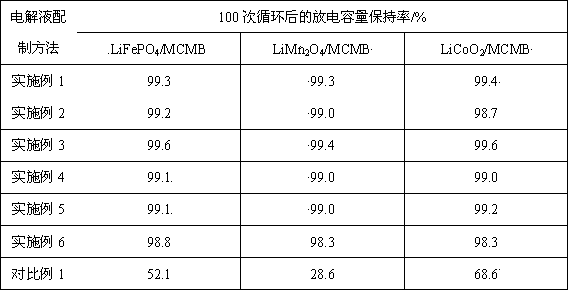

Examples

Embodiment 1

[0013] In this embodiment, the configuration process of the electrolyte is as follows: in an argon atmosphere, mix DEC and SL at a ratio of 1:1 by volume, and then add LiBOB to the mixed organic solvent to make a mass molar concentration of 0.5 mol / kg lithium salt solution, and then add LiBSO with a mass ratio of 10% 4 f 2 , after the additives are completely dissolved and mixed evenly, the electrolyte required by the invention can be prepared.

Embodiment 2

[0015] In this embodiment, in this embodiment, the configuration process of the electrolyte is as follows: in an argon atmosphere, mix GBL and DMS according to a volume ratio of 1:1, and then add LiBOB to the mixed organic solvent to form A lithium salt solution with a mass molar concentration of 1.2 mol / kg, and then adding LiBSO with a mass ratio of 3% 4 f 2 , after the additives are completely dissolved and mixed evenly, the electrolyte required by the invention can be prepared.

Embodiment 3

[0017] In this embodiment, in this embodiment, the configuration process of the electrolyte is as follows: in an argon atmosphere, mix GBL, SL, and EMC according to a volume ratio of 1:1:2, and then add to the mixed organic solvent LiBOB, made into a lithium salt solution with a mass molar concentration of 0.7 mol / kg, and then adding LiBSO with a mass ratio of 8% 3 f 2 , after the additives are completely dissolved and mixed evenly, the electrolyte required by the invention can be prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com