The production system and the production method of Angle's method for synthesizing hydrocyanic acid

A production system and technology of hydrocyanic acid, applied in the field of organic synthesis, can solve the problems of inability to determine the exact ratio of air, ammonia and natural gas, large resistance loss of the air conveying system, complicated process routes, etc., to reduce pipeline pressure loss, The effect of reducing energy consumption and simplifying the process route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

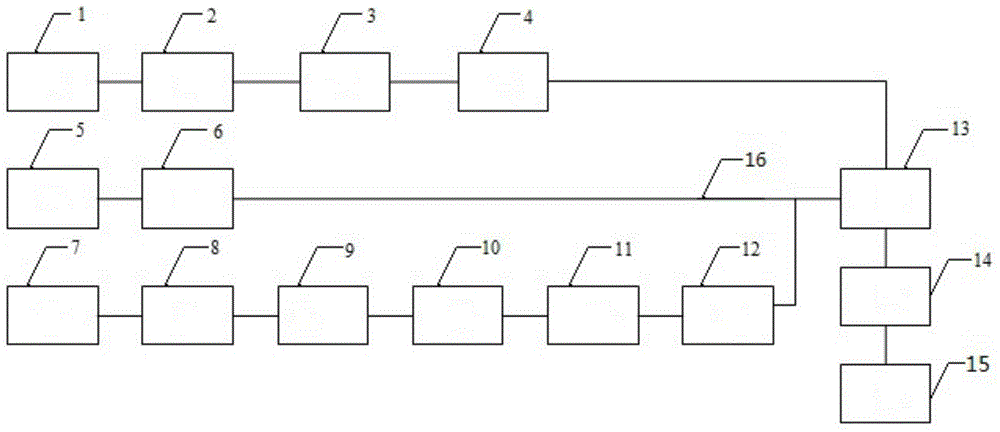

Image

Examples

Embodiment 1

[0037] The Angle method is the ammoxidation method, which is a method of converting ammonia sources, oxygen sources, and ammoxidable organic matter into cyanide at high temperature in the presence of an ammoxidation catalyst. The Angle method was proposed by L.Andrussow (L.Andrussow) of the German I.G company, and was the first to realize a method of industrialized production of hydrocyanic acid in Germany. The main raw materials used are methane, ammonia and oxygen, so it is also called Methane ammoxidation method or direct method. It uses platinum as a catalyst to produce hydrocyanic acid. At present, the Angle method is one of the main methods for the industrial production of hydrocyanic acid in foreign countries. The Angle method is mature in technology, economical and reasonable, and uses natural gas (methane) as raw material, which is rich in resources.

[0038] The invention provides a production system for synthesizing prussic acid by Angle's method, comprising a natu...

Embodiment 2

[0048] This embodiment provides a production method for the synthesis of prussic acid by the Angle method. Firstly, the purified heated air is mixed with purified and heated ammonia gas, and the mixed gas is mixed with purified and heated natural gas, and then passed through a flame arrester into the reactor to react.

[0049] As a preference, the above-mentioned purified and heated air is mixed with the purified and heated ammonia gas on the air pipeline, which simplifies the binary mixing device, and the three materials are preheated separately, which can avoid the three-component mixture in a large range. The explosion point of this gas; in the past, the air pressure obtained after using the reciprocating compressor air compressor to compress the air is 0.22Mpa, which is higher than the pressure required for the reaction. It is necessary to reduce the pressure. The process of reducing the pressure will increase the temperature. To meet the reaction temperature and need to c...

Embodiment 3

[0051] This embodiment provides a production method for Angle's synthesis of hydrocyanic acid. First, the purified air is heated to 80°C, the purified ammonia is heated to 80°C, the purified natural gas is heated to 80°C, and then Mix the purified and heated air with the purified and heated ammonia gas, mix with the purified and heated natural gas, and finally enter the reaction gas reaction through the flame arrester, measure the output of hydrocyanic acid, and calculate the consumption , it can be seen that every ton of hydrocyanic acid produced saves 12.3% of natural gas.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com