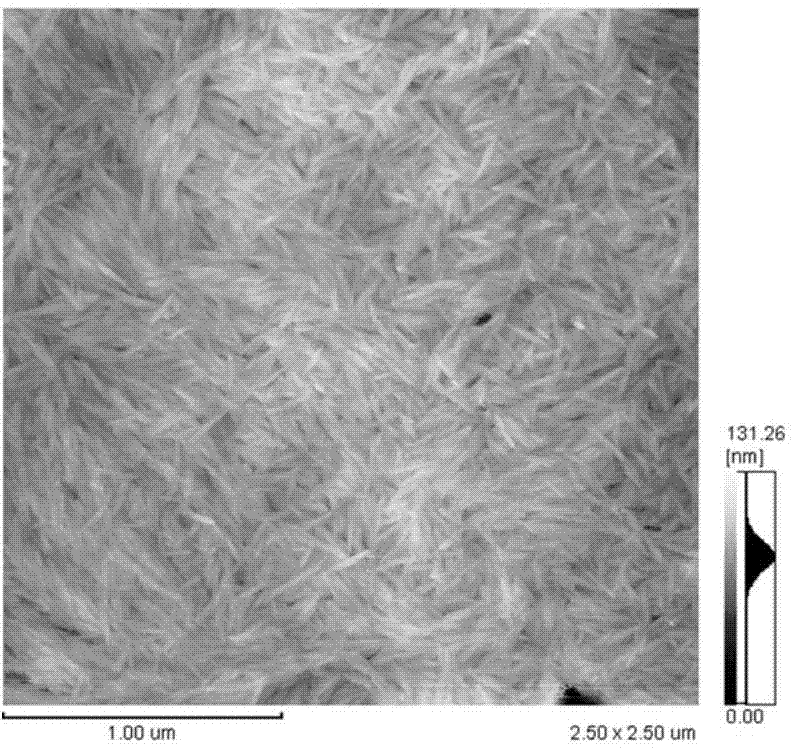

Cellulose nano-whisker (CNW) compounded bi-component terpenyl waterborne polyurethane and preparation method and use thereof

A technology of terpene-based water-based and water-based polyurethane, which is applied in cellulose adhesives, cellulose coatings, polyurea/polyurethane coatings, etc., to achieve the effects of simple manufacturing methods, improved performance, and enhanced interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

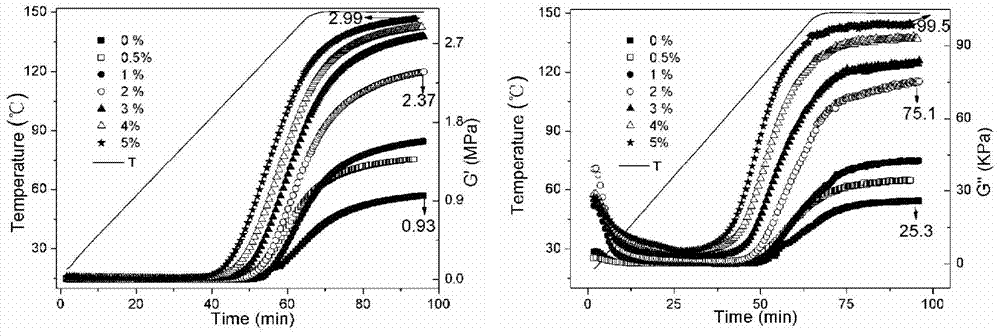

[0029] Example 1: The amount of CNW added is 0.5% of the quality of the two-component terpene-based waterborne polyurethane solid resin

[0030] Add 1.65g of CNW aqueous suspension (mass percentage concentration 3%) to 15.00g terpene-based epoxy resin polyol aqueous dispersion (solid content 35%wt), stir evenly, then add 5.85g water-based isocyanate crosslinking agent, Mix evenly, add 7.12g of water to dilute, then paint film on polytetrafluoroethylene board, leave it at room temperature for 2 days, then bake in 100°C oven for 1 hour, and measure the performance of the paint film. The tensile modulus of the composite product is 20.26MPa, the tensile strength is 13.12MPa, the storage modulus is 1.36MPa (150°C), and the loss modulus is 34.12KPa (150°C).

Embodiment 2

[0031] Embodiment 2: The amount of CNW added is 1% of the quality of the two-component terpene-based waterborne polyurethane solid resin

[0032] Add 1.77g of CNW aqueous suspension (mass percentage concentration 3%) to 8.00g terpene-based epoxy resin polyol aqueous dispersion (solid content 35wt%), ultrasonic 20min, then add 3.12g water-based isocyanate crosslinking agent, mix Evenly, after adding 2.92g of water to dilute, coat the film on a polytetrafluoroethylene board, place it at room temperature for 2 days, then bake it in an oven at 100°C for 1 hour, and measure the performance of the paint film. The composite product has a tensile modulus of 25.55MPa, a tensile strength of 13.77MPa, a storage modulus of 1.57MPa (150°C), and a loss modulus of 42.57KPa (150°C).

Embodiment 3

[0033]Embodiment 3: The amount of CNW added is 2% of the quality of the two-component terpene-based waterborne polyurethane solid resin

[0034] Add 3.53g of CNW water suspension (mass percentage concentration 3%) to 8.00g terpene-based epoxy resin polyol aqueous dispersion (solid content 35wt%), stir evenly, then add 3.12g water-based isocyanate crosslinking agent, mix Evenly, after adding 1.15g of water to dilute, coat the film in a polytetrafluoroethylene template, place it at room temperature for 2 days, then bake it in an oven at 100°C for 1 hour, and measure the performance of the paint film. The tensile modulus of the composite product is 34.33MPa, the tensile strength is 14.95MPa, the storage modulus is 2.38MPa (150°C), and the loss modulus is 75.13KPa (150°C).

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| storage modulus | aaaaa | aaaaa |

| loss modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com