Method for preparing fructus amomi volatile oil

A technology of volatile oil and amomum, which is applied in the directions of essential oil/fragrance, fat production, solid solvent extraction, etc., can solve the problems of difficult industrial scale production, low extraction rate, low cost, etc., to maintain original fragrance, high extraction efficiency, The effect of short preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

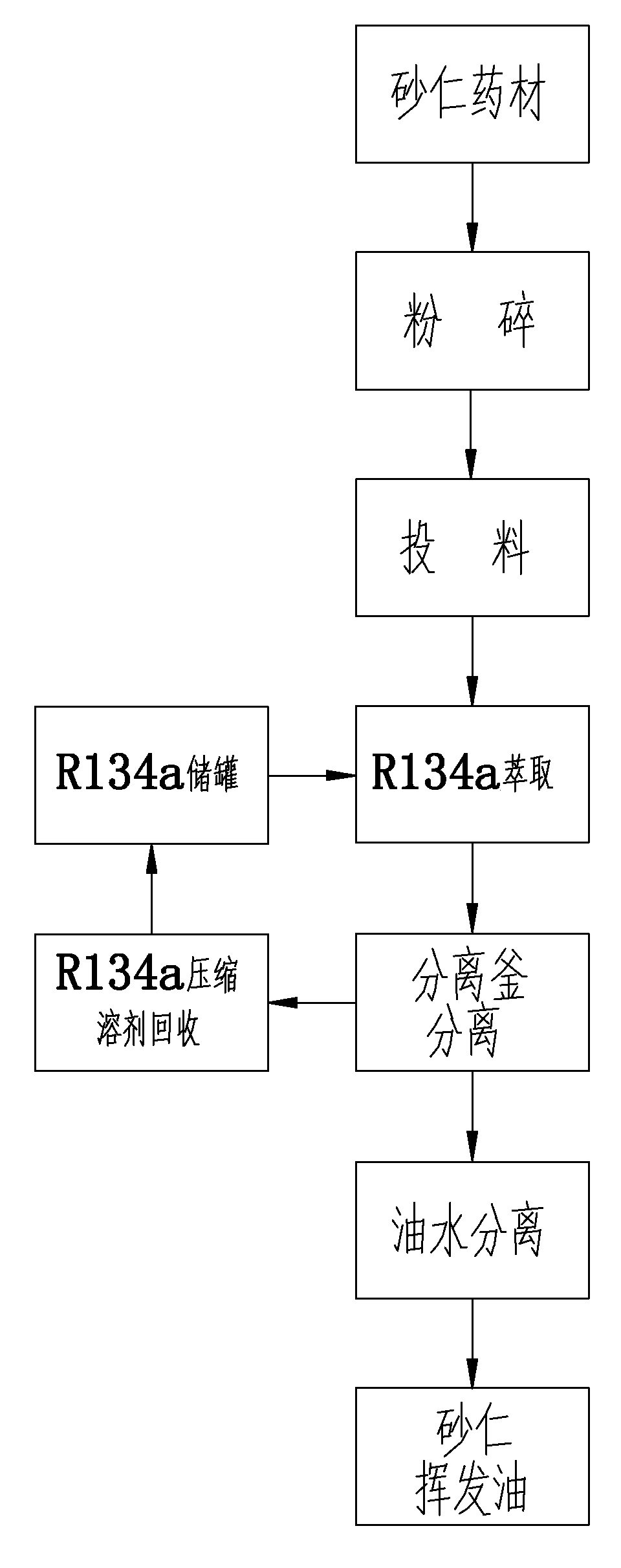

Method used

Image

Examples

Embodiment 1

[0022] (1) Raw material handling

[0023] Get dry Amomum medicinal material 50kg, detect wherein the content of Amomum volatile oil is 5.8%, it is pulverized into 20 order coarse powder, puts into 100 order filter bag, then filter bag is packed in the material column of subcritical extraction kettle ;

[0024] (2) Subcritical extraction

[0025] Add 500L 1,1,1,2-tetrafluoroethane into the extraction kettle as the extractant, extract for 40 minutes at a pressure of 1.1Mpa and a temperature of 30°C, put the extract into a separation kettle, and extract at a pressure of 0.1Mpa Next, the extraction agent is evaporated and recovered and used mechanically, and the remaining liquid is the Amomum volatile oil extract; repeat the above extraction process 3 times, and combine each Amomum volatile oil extract;

[0026] (3) Oil-water separation

[0027] The extract of Amomum volatile oil obtained in step (2) was left to stand for stratification, and oil-water separation was carried out...

Embodiment 2

[0030] (1) Raw material handling

[0031] Get 50kg of dried Amomum medicinal material, detect wherein the volatile oil content of Amomum is 6.0%, pulverize it into a 50-mesh coarse powder, put it into a 100-mesh filter bag, and then put the filter bag into the material column of the subcritical extraction kettle;

[0032] (2) Subcritical extraction

[0033] Add 200L 1,1,1,2-tetrafluoroethane into the extraction kettle as the extractant, extract for 60 minutes at a pressure of 0.3Mpa and a temperature of 40°C, put the extract into a separation kettle, and extract at a pressure of 0.06Mpa Next, the extraction agent is evaporated and recovered and used mechanically, and the remaining liquid is the Amomum volatile oil extract; repeat the above extraction process 5 times, and combine each Amomum volatile oil extract;

[0034] (3) Oil-water separation

[0035] The extract of Amomum volatile oil obtained in step (2) was allowed to stand for stratification, and then oil-water separa...

Embodiment 3

[0037] (1) Raw material handling

[0038] Get 50kg of dry Amomum medicinal material, detect wherein the Amomum volatile oil content is 6.4%, be pulverized into 40 mesh coarse powder, put into 100 mesh filter bag, then filter bag is packed in the material column of subcritical extraction kettle;

[0039] (2) Subcritical extraction

[0040] Add 1000L 1,1,1,2-tetrafluoroethane into the extraction kettle as the extractant, extract for 60 minutes at a pressure of 1.6Mpa and a temperature of 20°C, put the extract in a separation kettle, and extract at a pressure of 0.04Mpa Next, the extraction agent is evaporated and recycled, and the remaining liquid is the Amomum volatile oil extract; repeat the above extraction process 2 times, and combine each Amomum volatile oil extract;

[0041] (3) Oil-water separation

[0042] The extract of Amomum volatile oil obtained in step (2) was left to stand for stratification, and oil-water separation was carried out to obtain 3.0 L of Amomum vola...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com