Method for preparing high-purity rice protein peptide through high-pressure treatment and enzymolysis

A technology of rice protein peptide and rice protein, which is applied in the field of food technology, can solve the problems of low enzymatic hydrolysis rate and heat denaturation of rice protein, achieve the goals of wide sources, reduce peroxide, improve production performance and anti-stress ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

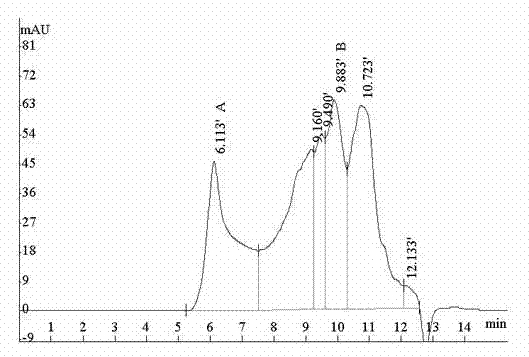

Embodiment 1

[0014] A method for preparing rice protein peptides by high-pressure treatment and enzymatic hydrolysis, the steps are as follows:

[0015] (1) Crushing of raw materials: Take 1Kg of rice dregs and grind them through an 80-mesh sieve;

[0016] (2) Impurity removal by amylase: Disperse the crushed rice dregs in water at a ratio of 8-10% (W / V), heat to 65°C, add high-temperature-resistant α-amylase (1500 U / kg protein), After incubating for 1.5 hours under stirring, centrifuge at 4000 rpm for 20 minutes; suspend the sediment at 12% (ratio of raw material and water) and heat to 45°C, add β-amylase, the amount of enzyme added is (500U / kg), After keeping warm for 2.5 hours under stirring conditions, centrifuge at 4000 rpm for 20 minutes; sediment washing: add hot water at 45°C at a ratio of 1:2 (ratio of raw material and water) to wash once, and the sediment is rice protein; the supernatant is recovered : The supernatant after two times of centrifugation and washing is recovered an...

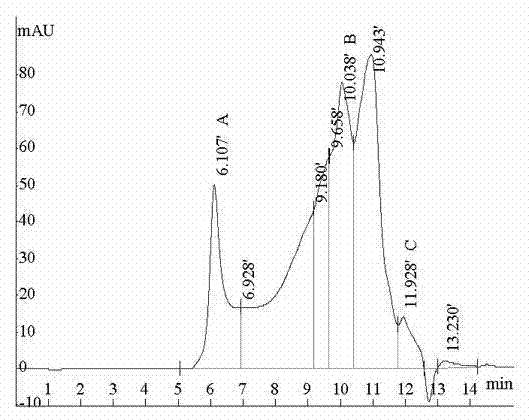

Embodiment 2

[0022] A method for preparing high-purity rice protein peptides by means of high-pressure treatment, the steps are as follows:

[0023] (1) Crushing of raw materials: Take 1Kg of rice dregs and grind them through an 80-mesh sieve;

[0024] (2) Impurity removal by amylase: disperse the crushed rice dregs into water at a ratio of 10% (W / V), heat to 70°C, and add high-temperature-resistant α-amylase (1500 U / kg protein) under stirring , after incubation for 1.5 hours, centrifuge at 4000 rpm for 20 minutes; suspend the sediment at 12% (ratio of raw material and water) and heat to 45°C, add β-amylase (500 U / kg), stir After incubating for 2.5 hours under the same conditions, centrifuge at 4000 rpm for 20 minutes; sediment washing: add hot water at 45°C to wash once at a ratio of 1:2 (raw material to water ratio), the sediment is rice protein, and the supernatant is recovered: The supernatant after two times of centrifugation and washing is recovered and used for soaking the next bat...

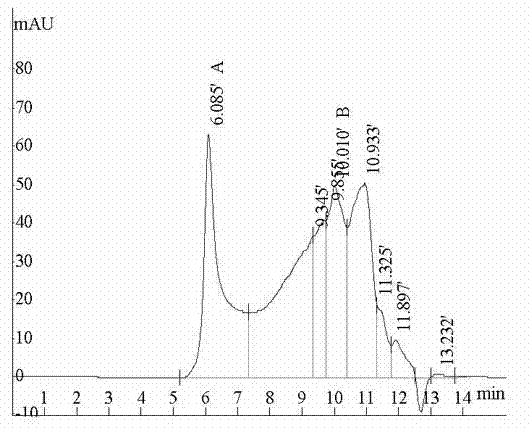

Embodiment 3

[0030]A method for preparing high-purity rice protein peptides by high-pressure treatment and enzymolysis, the steps of which are as follows:

[0031] (1) Pulverize the rice dregs, pass through a 80-mesh sieve, disperse the rice dregs in water, the mass concentration of the rice dregs in water is 8%, soak for 1-2 hours;

[0032] (2) Heat the soaked rice dregs to 65°C, add high-temperature-resistant α-amylase, the ratio of high-temperature-resistant α-amylase to rice dregs is 1000 U / kg, keep it warm for 1.0 h under stirring, and heat at 3500 rpm Centrifuge for 20 minutes under the condition of 1 minute to obtain the rice dregs sediment for the first time; add water to the rice dregs sediment for the first time, the mass concentration of the first rice dregs sediment in water is 10%, stir and heat to 45 ℃, add β-amylase, the ratio of β-amylase to rice dregs is 500 U / kg, keep warm for 2.5 h under stirring conditions, centrifuge at 3500 rpm for 20 minutes, and obtain the second ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com