A cladding method for wear-resistant coating on the surface of magnesium-based alloy

A magnesium-based alloy and wear-resistant coating technology, which is applied in the field of cladding of wear-resistant coatings on the surface of magnesium-based alloys, can solve problems such as reduced service life of equipment or parts, failure to form battery circuits, and failure to thicken deposit layers , to achieve the effects of short cladding time, increased thickness, increased thickness and hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

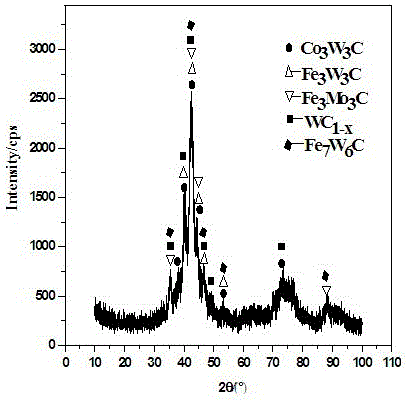

Image

Examples

Embodiment 1

[0021] (1) Pretreatment of the surface of the workpiece: before cladding the surface of the magnesium-based alloy, firstly grind it with a hand-held grinder to remove surface oxide scales and rust spots, and then clean the surface of the workpiece with alcohol or acetone to remove dirt.

[0022] (2) The magnesium-based alloy is used as the cladding substrate, and the ceramic carbide WC is used as the electrode. The electrode is a rotating electrode with a rotation speed of 2700r / min, an electrode diameter of Ф8mm, and an electrode elongation of 15mm. Under gas protection, thermal cladding equipment is used for processing; cladding process parameters are: cladding power 4000, cladding voltage 280V, cladding frequency 2500HZ.

[0023] With the above-mentioned high output power treatment, a larger liquid molten pool can be formed, which increases the thickness of the cladding layer and the diffusion of elements in the heat-affected zone; at the same time, a large flow of protectiv...

Embodiment 2

[0028] (1) Pretreatment of the surface of the workpiece: before cladding the surface of the magnesium-based alloy, firstly grind it with a hand-held grinder to remove surface oxide scales and rust spots, and then clean the surface of the workpiece with alcohol or acetone to remove dirt.

[0029] (2) Magnesium-based alloy is used as the cladding substrate, ceramic carbide WC-8Co is used as the electrode, the electrode is a rotating electrode, the rotation speed is 2800r / min, the diameter of the electrode is Ф9mm, and the elongation of the electrode is 20mm. Under the protection of inert gas, use thermal cladding equipment for processing; cladding process parameters are: cladding power 5000, cladding voltage 300V, cladding frequency 2800HZ;

[0030] (3) The electrode is in contact with the substrate surface, and the electrode adopts a spiral reciprocating processing method;

[0031] (4) The hardness of the cladding layer is 1700~1900HV, and the thickness of the cladding layer is...

Embodiment 3

[0033] (1) Pretreatment of the surface of the workpiece: Before cladding the surface of the magnesium-based alloy, firstly polish it with sandpaper to remove surface scale and rust spots, and then clean the surface of the workpiece with alcohol or acetone to remove dirt.

[0034] (2) Magnesium-based alloy is used as the cladding substrate, ceramic carbide WC-8Co is used as the electrode, the electrode is a rotating electrode, the rotation speed is 3000r / min, the diameter of the electrode is Ф10mm, and the elongation of the electrode is 30mm. Under the protection of inert gas, use thermal cladding equipment for processing; cladding process parameters are: cladding power 6000, cladding voltage 380V, cladding frequency 3000HZ;

[0035] (3) The electrode is in contact with the substrate surface, and the electrode adopts a spiral reciprocating processing method;

[0036] (4) The hardness of the cladding layer is 1700~1900HV, and the thickness of the cladding layer is 210~230μm. Wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elongation | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com