Coating on heat exchange sheet of heat exchange device and method for removing dirt

A technology of heat exchange device and heat exchange sheet, which is applied to the coating on the heat exchange sheet of the heat exchange device and the field of scaling removal, which can solve the problems of easy scaling, scaling is difficult to clean, and can only be stopped for cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

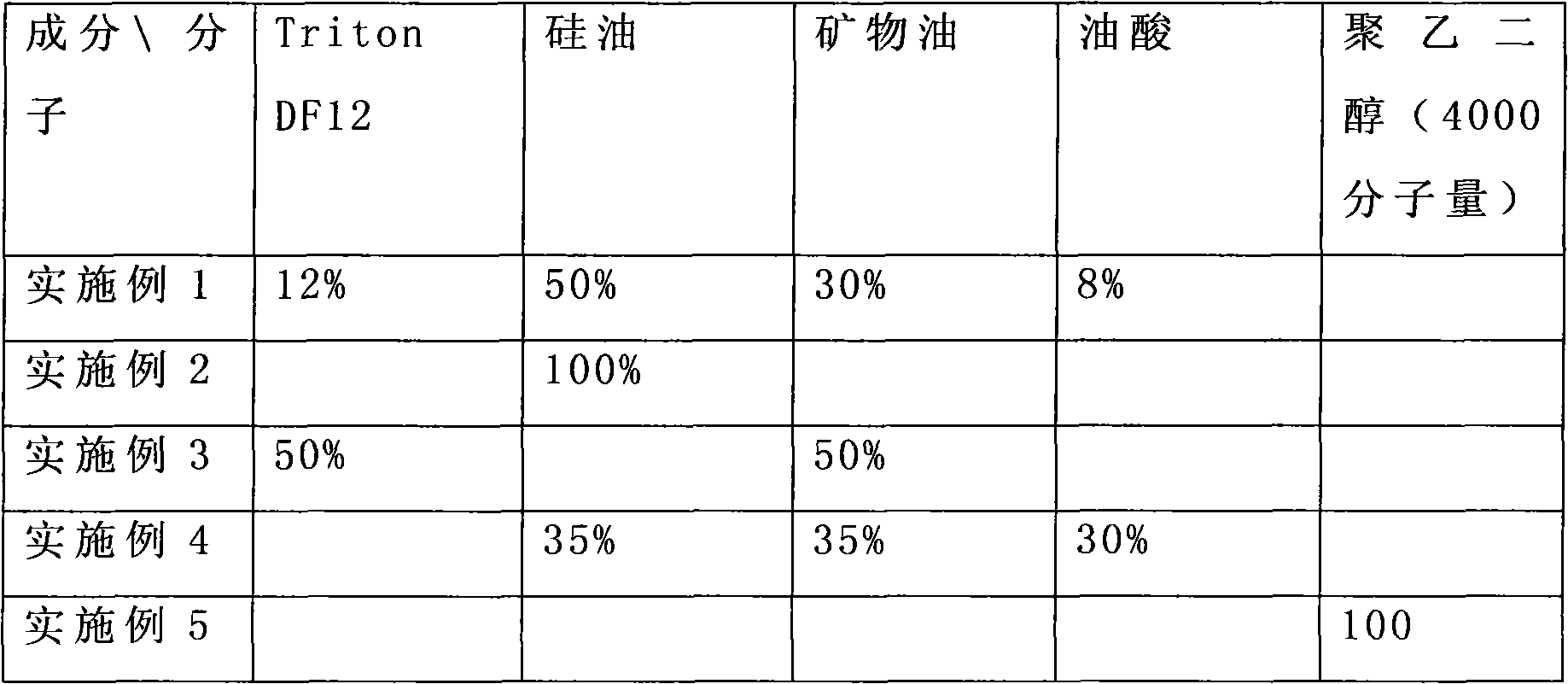

[0031] The composition of antiscalant coating materials for heat exchange units is listed in the table below.

[0032]

[0033] TRITON DF12 in the above table is a Dow fatty chain polyoxyethylene ether.

[0034] The mineral oil in the above table is the high boiling point oil produced by refining the residue after the petrochemical industry refines the fuel oil.

[0035] Material composition of simulating fouling of heat exchange device and method of simulating fouling on heat exchange fins of heat exchange device.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com