Method and device for detecting surface defects and thickness of semiconductor sheet material

A technology of thickness detection and detection method, applied in the direction of measuring device, using optical device, optical testing defect/defect, etc., can solve the problems of large influence of impurities and pollution, poor repeatability, unsuitable thickness of film, etc., to achieve repeatability High, easy to operate, low sample requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

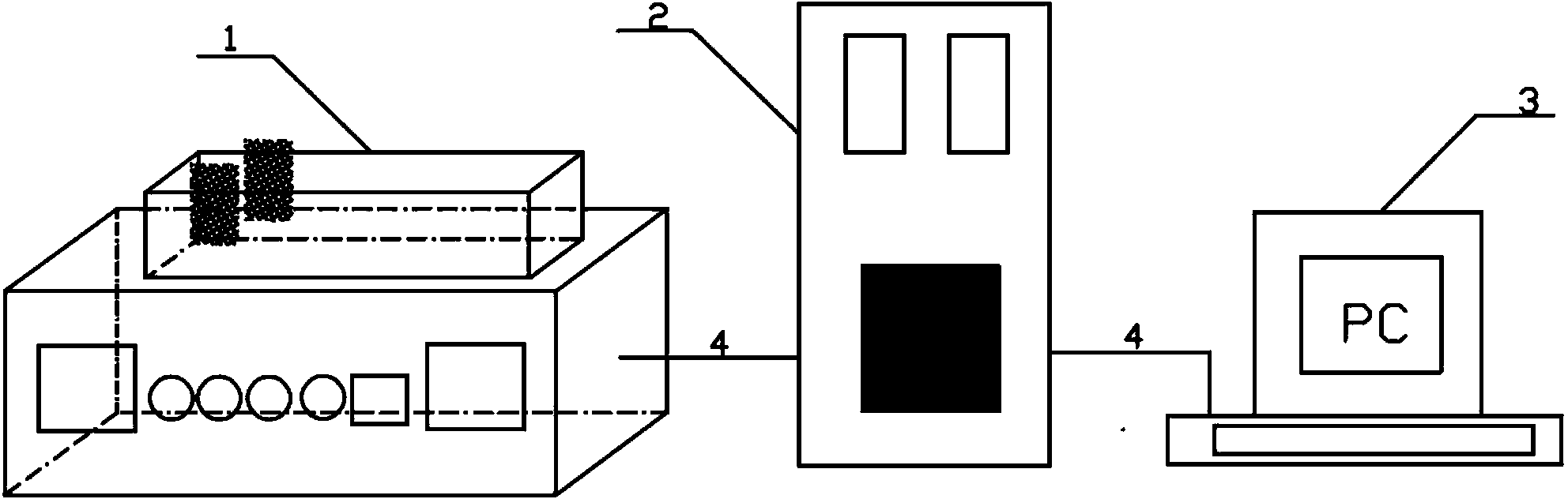

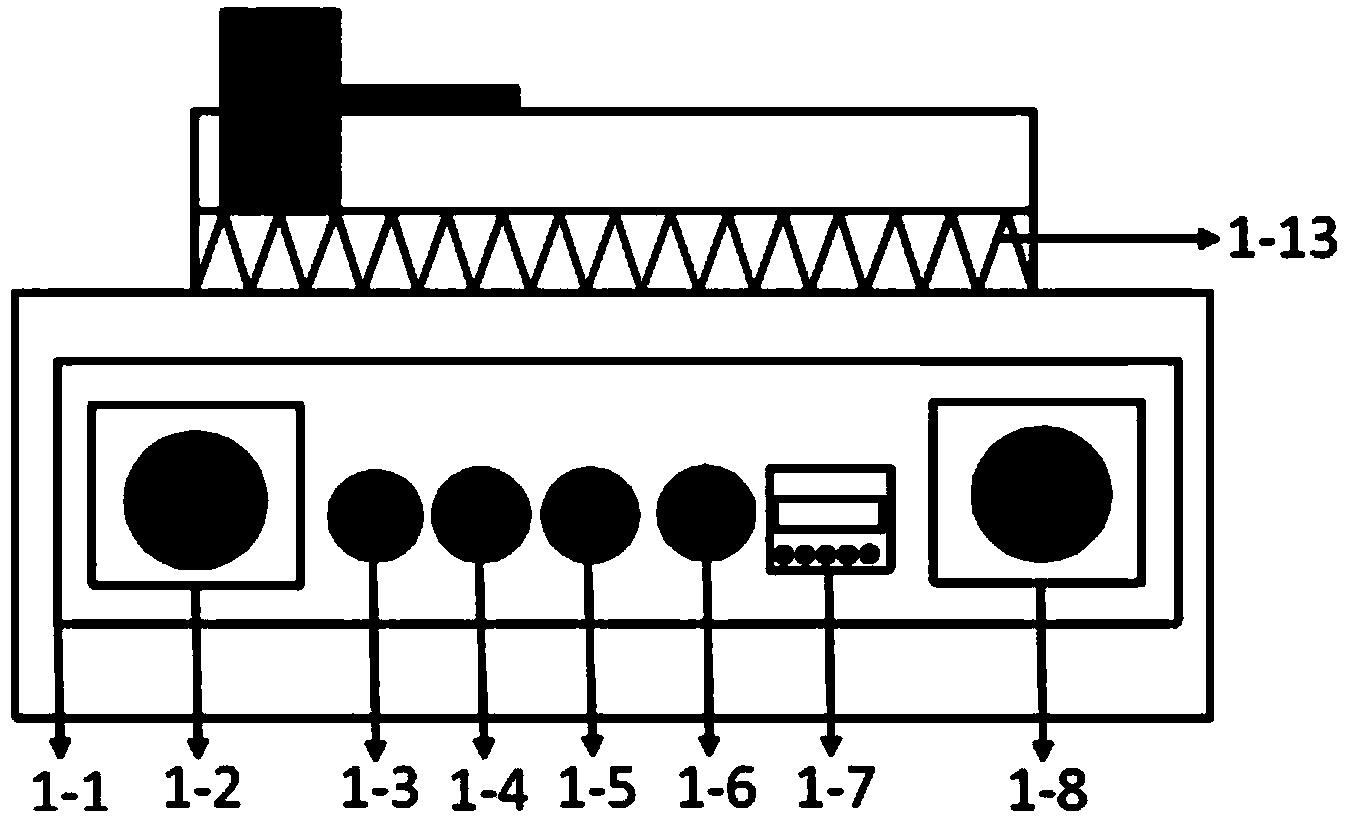

[0039] Embodiment 1: the present invention has the solution of detection method and device, and this detection device comprises frock 1, control cabinet 2, computer 3 and connecting cable 4, and frock 1, control cabinet 2 and computer 3 are connected in sequence by connecting cable 4 . figure 1 , figure 2 , image 3 and Figure 4 The solution of the detection method and device of the present invention is described.

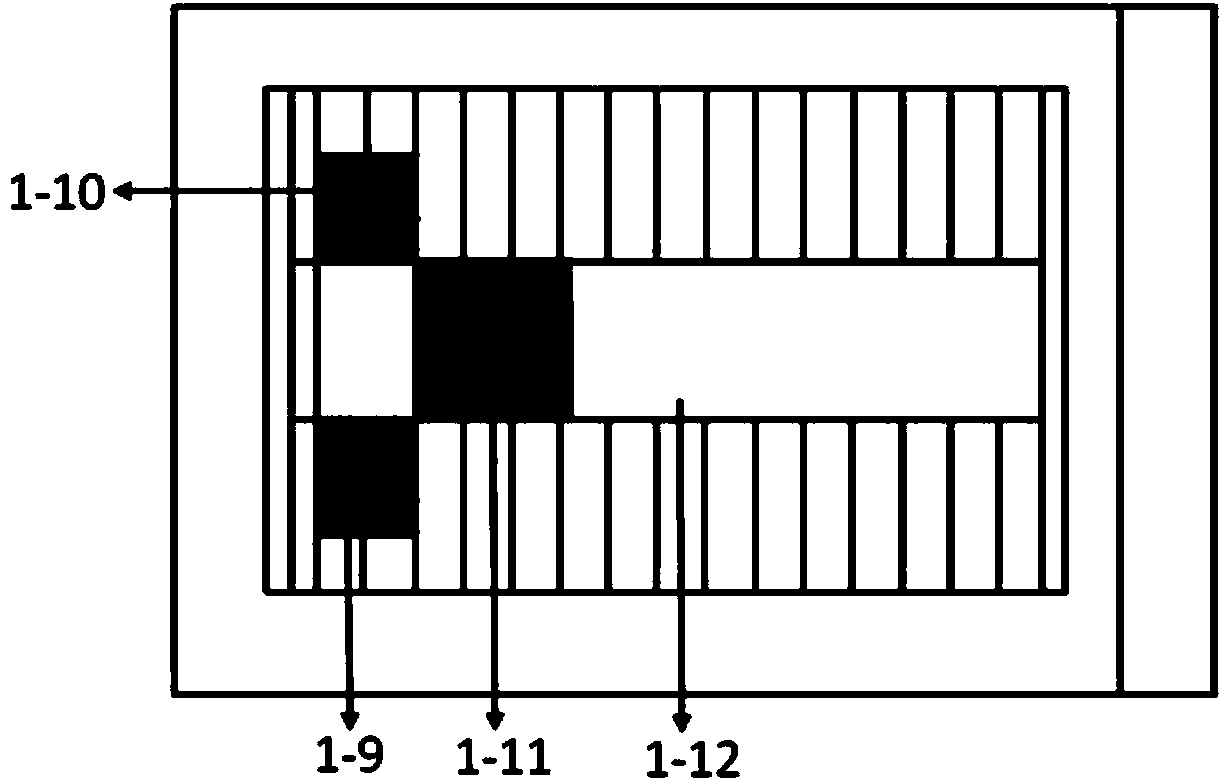

[0040] The tooling 1 includes: a control panel 1-1, a laser generator 1-9, a laser receiver 1-10, a test platform 1-12, a protection device 1-13, a synchronous operation system 1-15, a test platform support and Level adjustment system 1-16, power system 1-17 and base plate 1-19. All components of the tooling 1 are installed on the base plate 1-19, a control panel 1-1 is connected to the front of the tooling 1, and a laser generator 1-9, a laser receiver 1-10, and a test platform are connected to the upper end of the tooling 1 1-12 and the protection device 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com