Moving-iron cableless six-degree-of-freedom magnetic levitation motion platform with vacuum cover

A technology of motion platform and degree of freedom, applied in the direction of photolithography exposure device, microlithography exposure equipment, etc., can solve the problems of cable interference movement, performance limitation, etc., to improve control bandwidth, prevent drift, and improve anti-interference ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

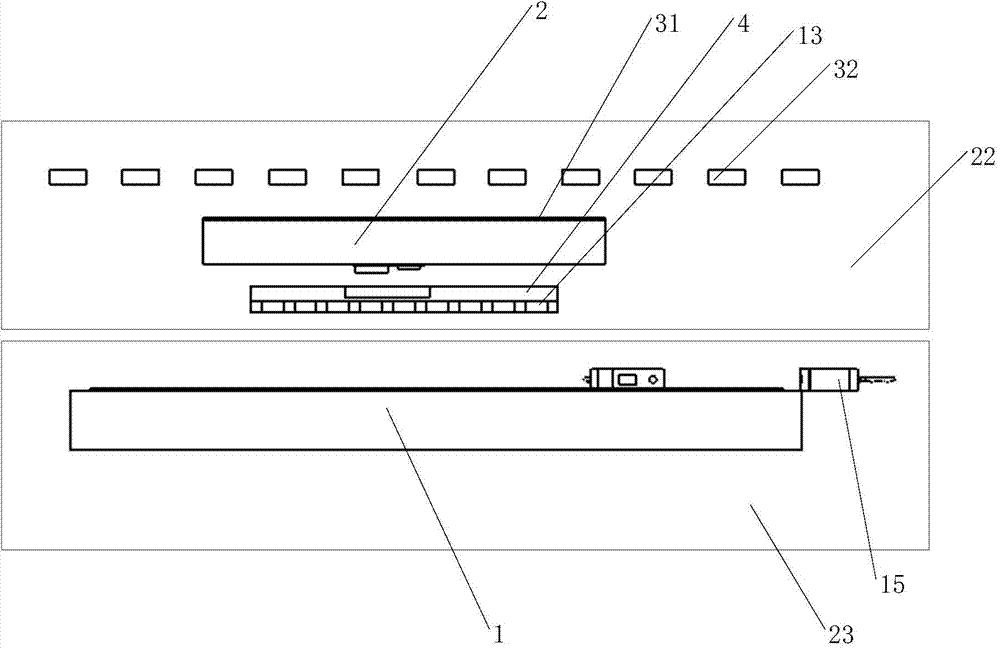

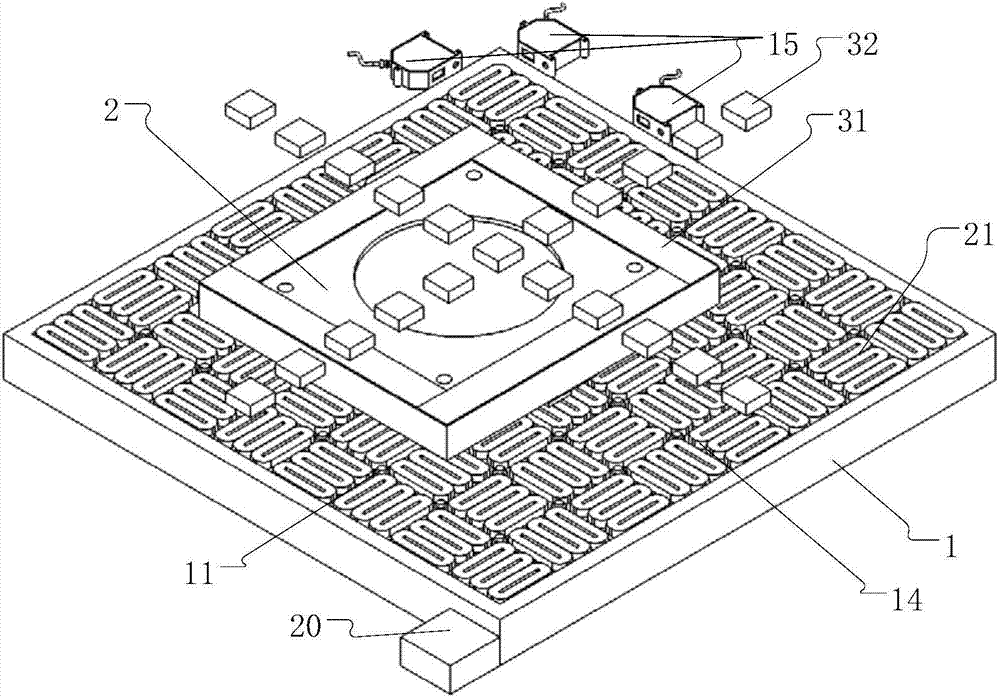

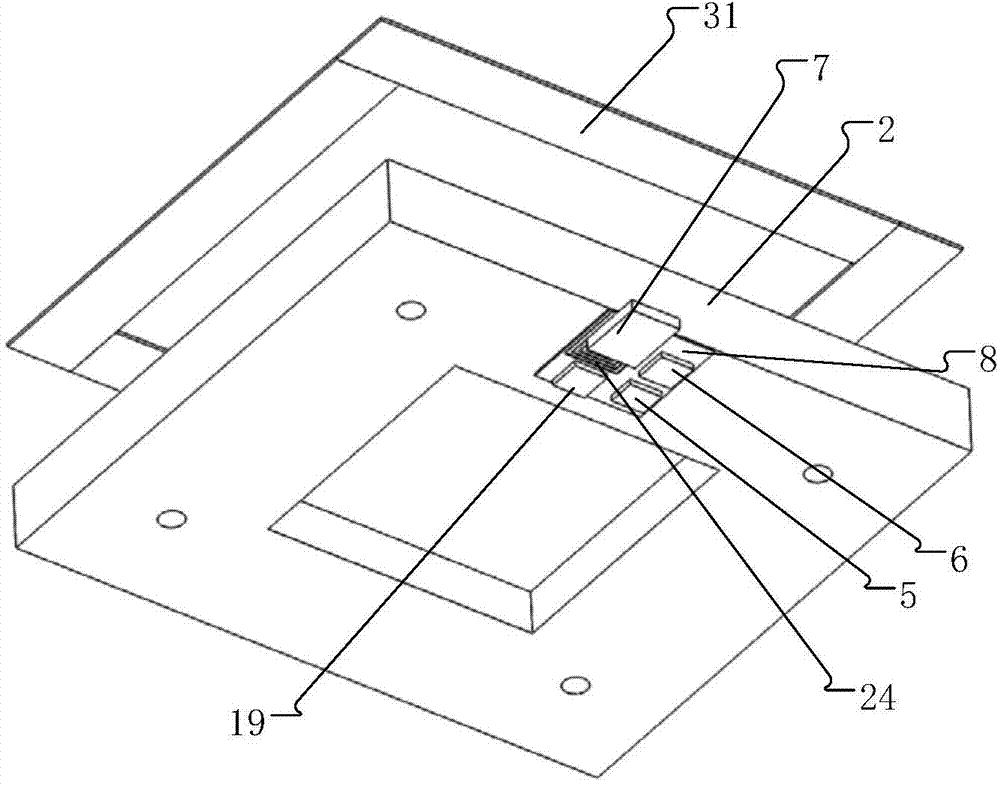

[0023] figure 1 Schematic diagram of the structure of a moving iron cable-free six-degree-of-freedom maglev motion platform with a vacuum cover provided by the present invention, figure 2 A three-dimensional exploded structure diagram for removing the vacuum cavity of the mover and the vacuum cavity of the stator; the maglev motion platform includes a base 1, a stator, a mover, a slide table 2 and a measurement system, and the mover contains a Halbach permanent magnet array 13 and The magnetic steel backboard 4; the stator is a coil array 14 formed by a plurality of groups of coil units 9; the measurement system includes a plane grating ruler measurement system 12, an eddy current sensor 11 and a laser triangulation sensor 15; A three-axis gyroscope 5, a three-axis accelerometer 6, a power module 7 and a wireless signal output module 19 are also provided between the moving element and the slide table 2; the three-axis gyroscope 5, the three-axis acceleration The meter 6, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com