Conductive film and method for producing same, and sputtering target used for same

A technology of a conductive film and a manufacturing method, which is applied in the field of sputtering targets, can solve the problems of the decline in the production yield of organic EL panels, the inability to obtain sufficient heat resistance, and the small surface roughness, so as to suppress defects and prevent the decline of the yield. , the effect of maintaining reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

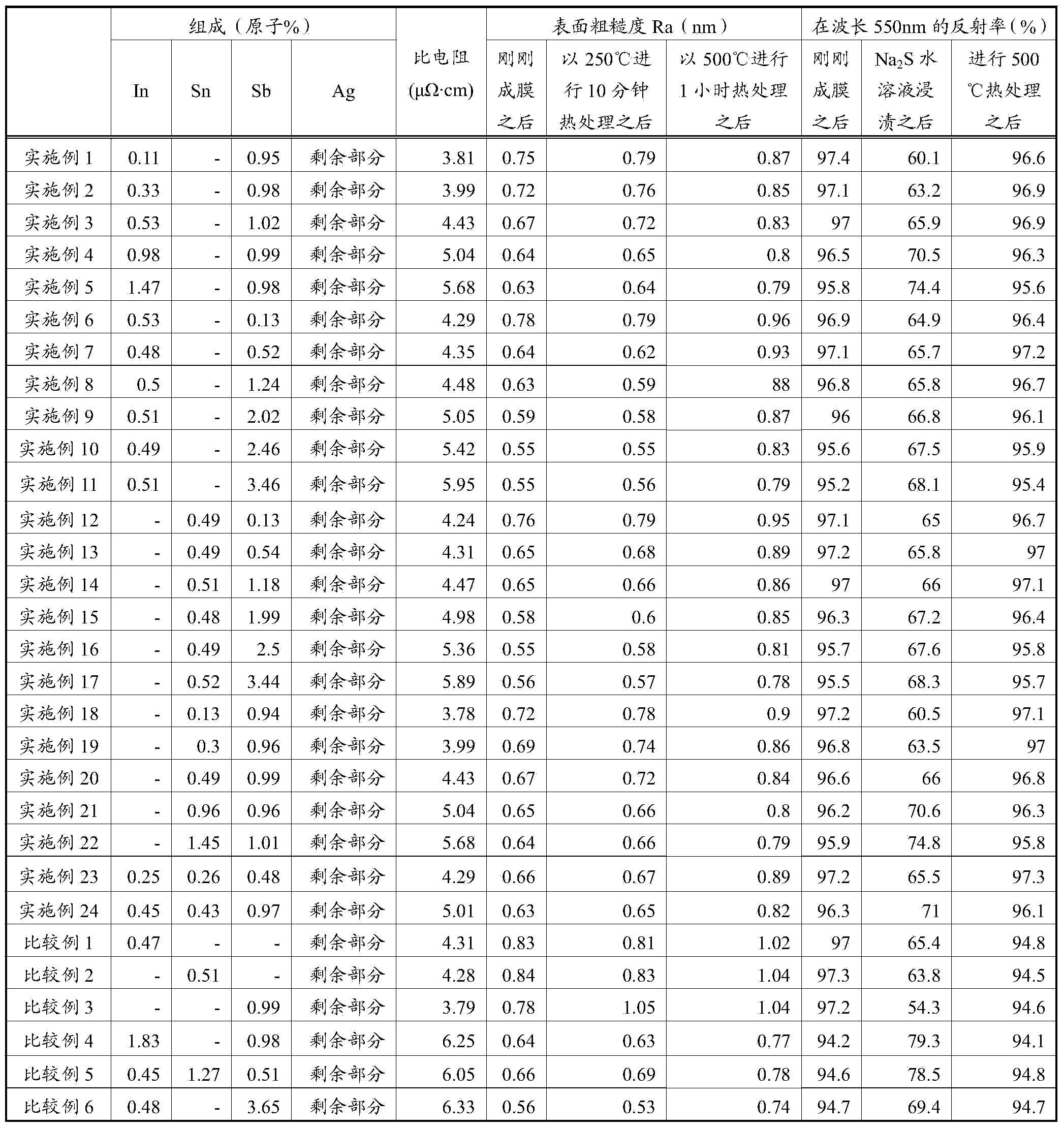

[0043] Hereinafter, the evaluation results of examples of the conductive film formed according to the above-mentioned embodiment will be described. First, in order to produce a sputtering target for a conductive film, Ag with a purity of 99.9% by mass or more, at least one of In and Sn with a purity of 99.9% by mass or more, and Sb are used as raw material powders so that they have a predetermined composition. weighing. Next, Ag is melted in a high vacuum or an inert gas atmosphere, and at least any one of In and Sn and Sb are added to the obtained molten metal in predetermined contents. Thereafter, melting is carried out in a vacuum or an inert gas atmosphere to manufacture a smelted ingot of an Ag alloy composed of the following components: the silver alloy contains 0.1 to 1.5 atomic % of at least one of In and Sn, and contains 0.1 to 3.5 The atomic % is Sb, and the rest is composed of Ag and unavoidable impurities.

[0044] Among them, the melting of Ag is carried out in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com