Stichopus japonicus feed and preparation method and application thereof

A sea cucumber and feed technology, applied in the application, animal feed, animal feed and other directions, can solve the problem of insufficient price and nutrients, and achieve the effect of ensuring nutritional needs, reducing use, reducing energy loss and vitality loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

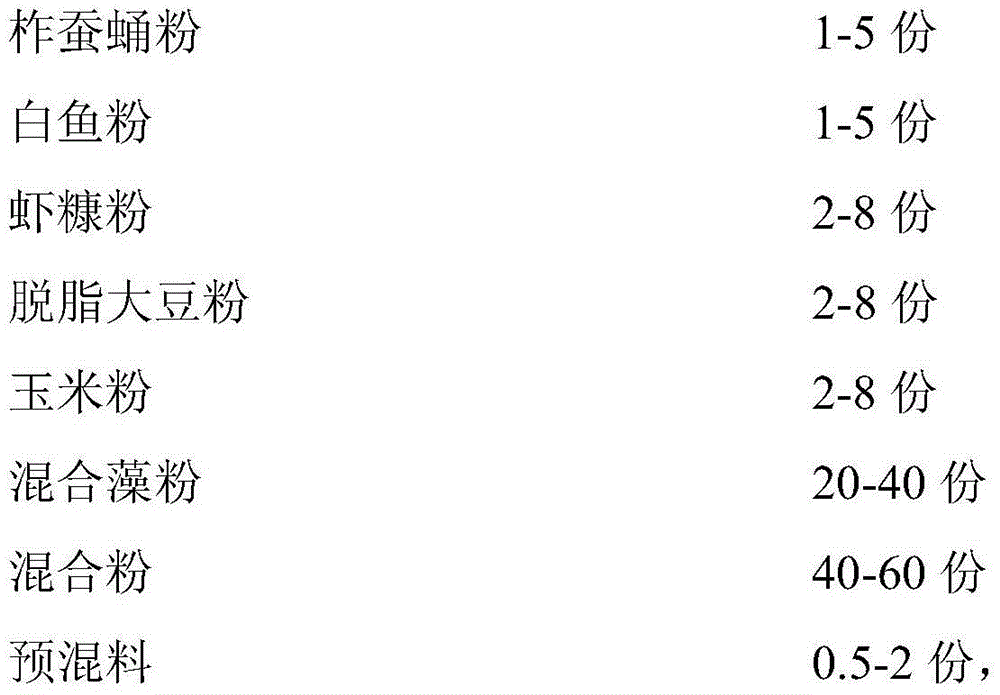

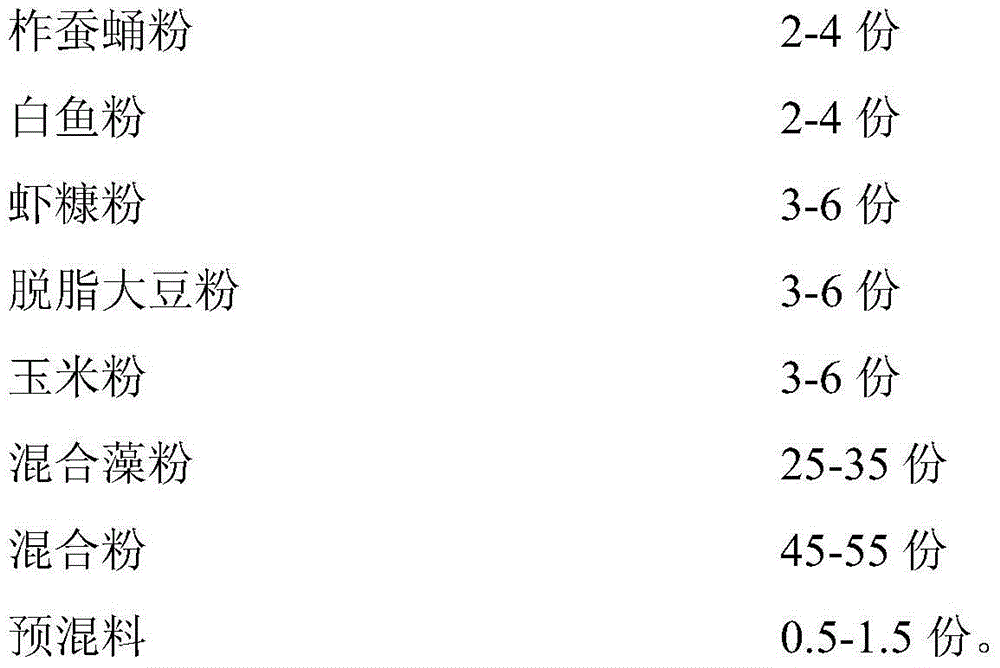

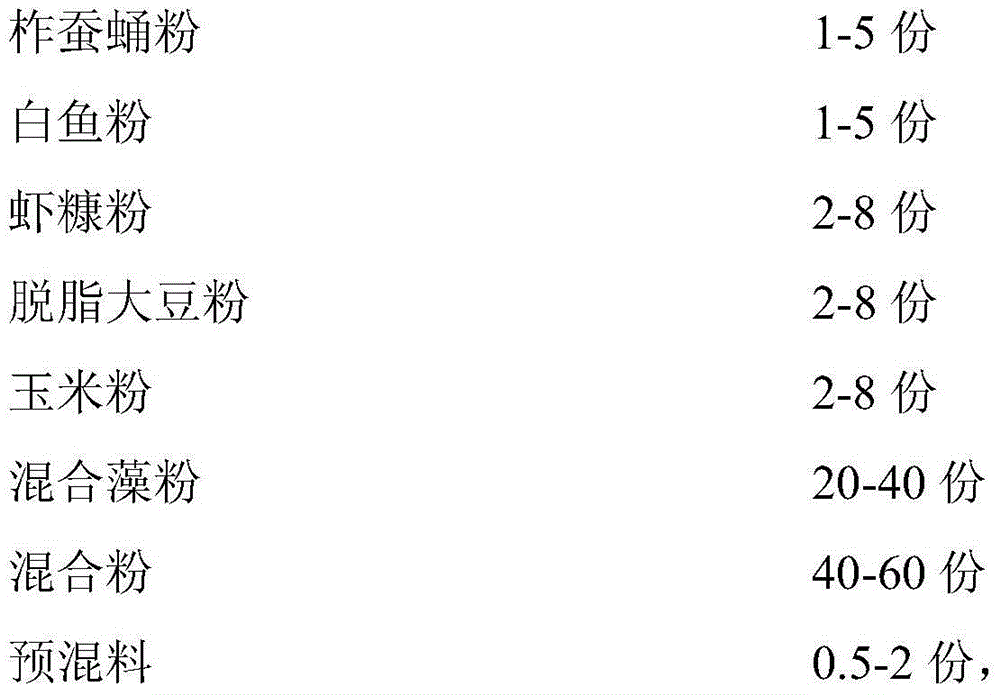

Method used

Image

Examples

Embodiment 1

[0025] ① Preparation of tussah silkworm chrysalis powder: Take 12 kg of tussah silkworm chrysalis, use Streptococcus tussah silkworm as the induction source, and adjust the bacterial concentration to 10 with sterile physiological saline. 7 1 / mL, injected into pupal body, inject 0.25 μL per silkworm pupae, culture at 22°C for 4-6 days, then break pupae body, centrifuge (room temperature, 5000rpm, 15min) to remove pupae shell and pupae body material, and then After spray drying, 2 kg of pupa powder can be obtained.

[0026] ② Mixing of raw materials: 2 kg of immune tussah silkworm chrysalis powder, 2 kg of white fish meal, 4 kg of shrimp bran powder, 4 kg of defatted soybean powder, 4 kg of corn flour, sargassum powder and sargassum powder prepared in the above step ① according to the quality 24 kg of mixed algae powder with a ratio of 3:1, sea mud powder and oyster powder are fully mixed with 39.2 kg of mixed powder and 0.8 kg of premix in a ratio of 1:1 by mass. The mixing pro...

Embodiment 2

[0029] ① Mixing of raw materials: 4 kg of white fish meal, 4 kg of shrimp bran powder, 4 kg of defatted soybean meal, 4 kg of corn meal, 24 kg of mixed algae powder with a mass ratio of 3:1 , sea mud powder and oyster powder are fully mixed with 39.2 kg of mixed powder and 0.8 kg of premix according to the mass ratio of 1:1. The mixing process is carried out in batches in the KCH-10V mixer.

[0030] ②Granulation of raw materials: The mixture in the above step ① is made into granules with a granulator.

Embodiment 3

[0032]Choose 10 kilograms of feed prepared in Example 1 to directly feed sea cucumbers, and the feeding time is 60 days. The volume of the culture tank is 1 cubic water body, the stocking density is 1 jin / cubic water body, and the pond is poured once every 7 days. The weight ratio of sea cucumber is 7:100.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com