Truffle microcapsule and preparation method and application thereof

A technology of microcapsules and chitosan microcapsules, which is applied in the field of edible fungus preservation biotechnology processing, can solve the problems of no research reports on truffle microcapsules, and achieve the effects of being beneficial to human body absorption, long storage period, and less loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

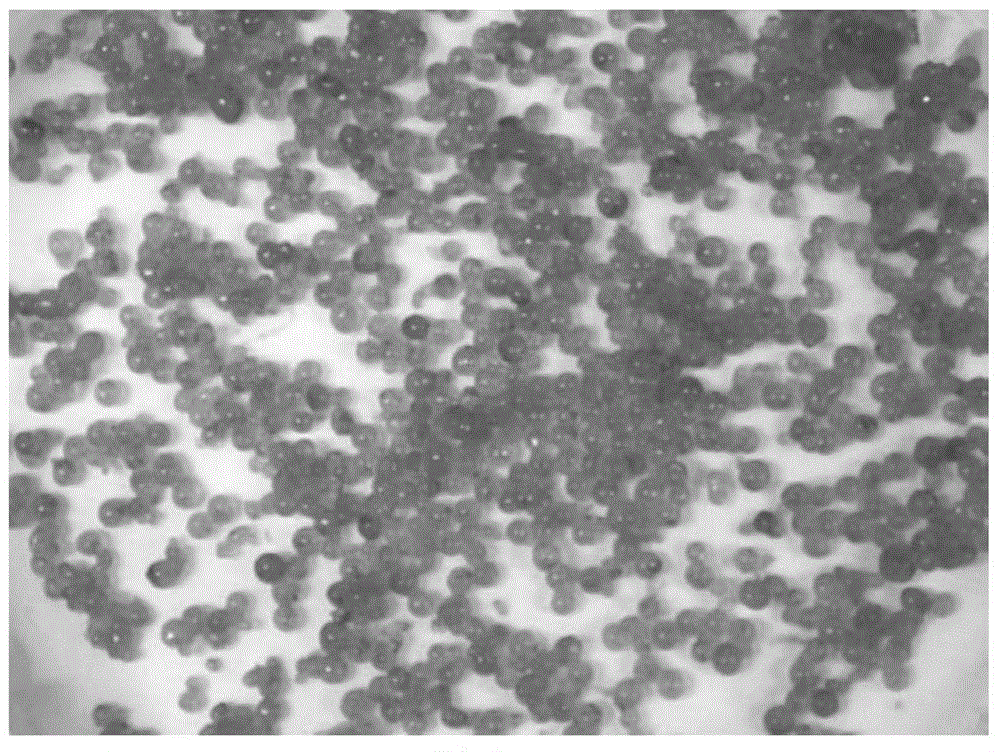

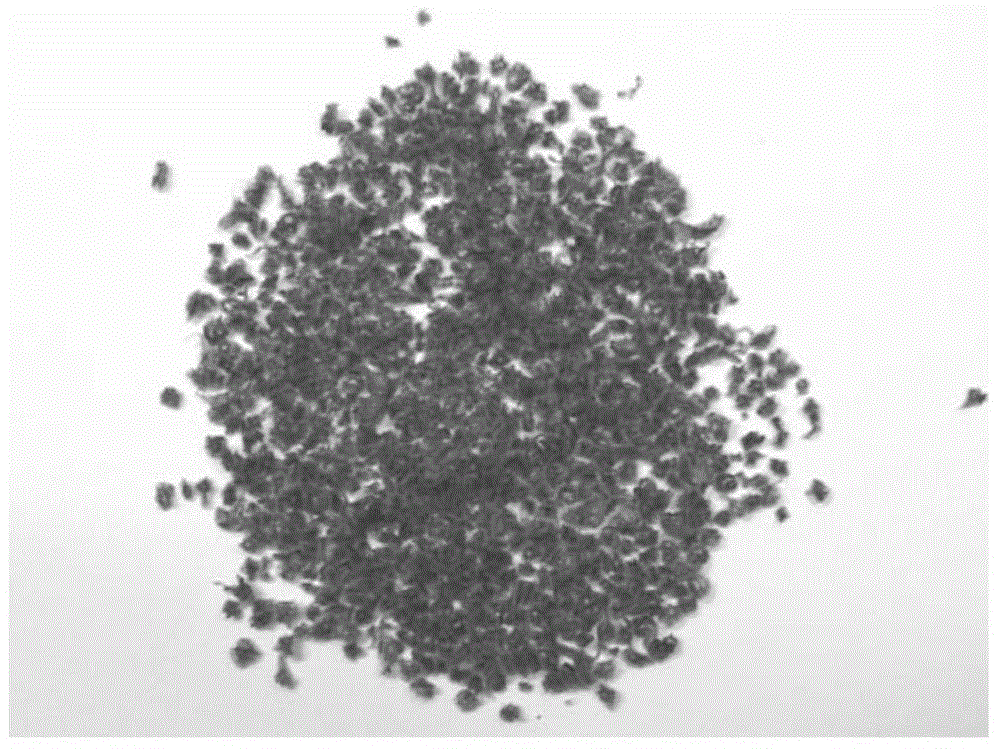

Image

Examples

preparation example Construction

[0021] The preparation method of truffle microcapsules of the present invention comprises the following steps:

[0022] (1) Preparation of solidification solution: Dissolve 1-5g of chitosan, 10-50g of calcium chloride and 1-5ml of acetic acid solution per 1000ml of water;

[0023] (2) Refining: According to the weight ratio, take 100 parts of fresh truffles, 200-400 parts of water, and use a colloid mill or tissue homogenizer to refine to obtain truffle pulp. The truffle core material particles in the truffle pulp are controlled at 2 -200um;

[0024] (3) Preparation of sodium alginate-truffle mixture: according to the weight ratio, take 10-30 parts of sodium alginate, slowly add 1000 parts of 90-100 ℃ water, after completely melting, cool to 50 ℃, add step (2 60-120 parts of truffle slurry prepared in ), mechanically stirred or high-pressure homogenized to obtain sodium alginate-truffle mixture;

[0025] (4) According to the volume ratio, take 400-600 parts (preferably 500 p...

Embodiment 1

[0035] (1) Dissolve 2 g of chitosan, 20 g of anhydrous calcium chloride, and 5 ml of acetic acid solution in 1000 ml of purified water to obtain a solidified microcapsule solution for use.

[0036] (2) Break 100g of fresh and mature Indian truffles into small particles with a common meat grinder, add 200g of pure water, first adjust the gap between the stator and rotor of the colloid mill to 200um, add the truffle raw material to the colloidal mill for 3 minutes, and then adjust the gap between the stator and rotor 20um, continue rubber milling for 5min to obtain truffle slurry.

[0037] (3) Take 10g of sodium alginate and slowly add it to 1000ml of boiled pure water. After it is completely dissolved, cool it down to 50°C, add 90g of the truffle slurry prepared in step (2), and stir quickly to obtain sodium alginate- Truffle mixture.

[0038] (4) Take 500ml of the sodium alginate-truffle mixture solution and add it dropwise to 1000ml of the solidified solution with a 0.6mm sy...

Embodiment 2

[0041] (1) Dissolve 5 g of chitosan, 40 g of anhydrous calcium chloride, and 1 ml of acetic acid solution in 1000 ml of purified water to obtain a solidified microcapsule liquid for use.

[0042] (2) Break 100g of fresh and mature summer truffles into small particles with an ordinary meat grinder, add 300g of pure water, first adjust the gap between the stator and rotor of the colloid mill to 1mm, add the truffle raw material to the colloidal mill for 3 minutes, and then adjust the gap between the stator and rotor 200um, continue rubber milling for 3 minutes to obtain truffle slurry.

[0043] (3) Take 20g of sodium alginate and slowly add it to 1000ml of boiled pure water. After it is completely dissolved, cool it down to 50°C, add 120g of the truffle slurry prepared in step (2), and stir quickly to obtain sodium alginate- Truffle mixture.

[0044] (4) Take 300ml of the sodium alginate-truffle mixture solution and add it dropwise to 1000ml of the solidification solution with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com