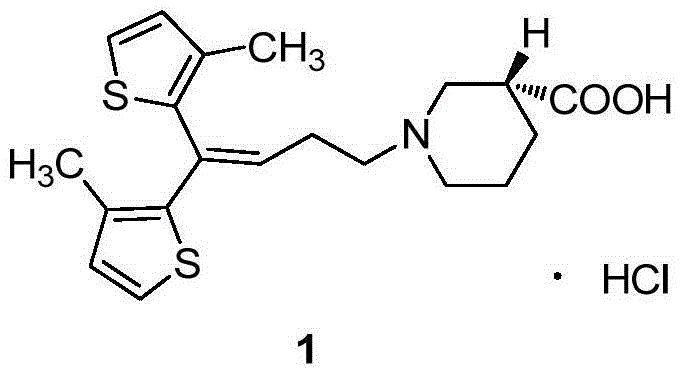

Tiagabine ethyl ester hydrochloride and preparation method thereof

A technology of tiagabine ethyl ester and hydrochloride, which is applied in the field of tiagabine ethyl ester hydrochloride and its preparation, can solve the problems of difficult separation and purification, and achieve the effect of easy control of impurity content and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

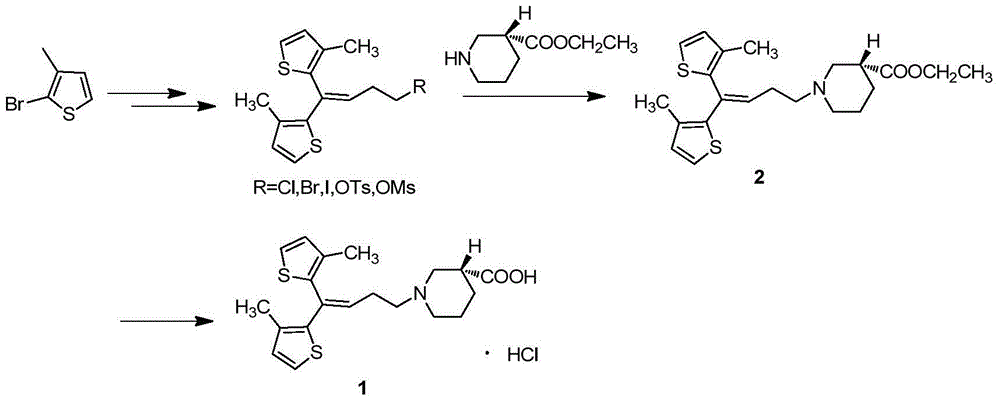

Method used

Image

Examples

Embodiment 1

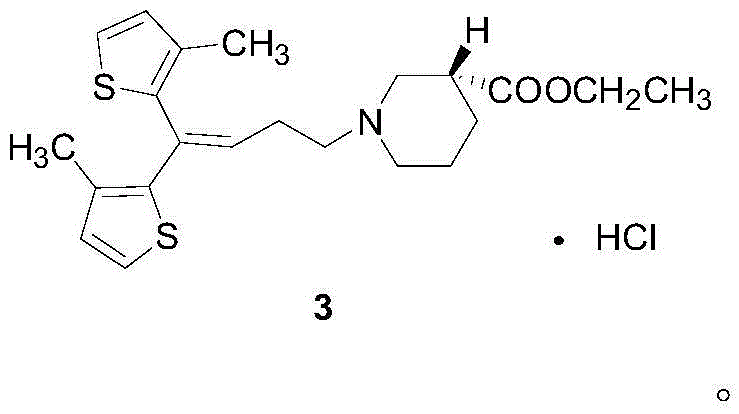

[0031] The preparation method of embodiment 1 tiagabine ethyl ester hydrochloride

[0032] Dissolve 10g of tiagabine hydrochloride finished product in 50mL of ethanol, add 6mL of concentrated hydrochloric acid dropwise, heat the reaction at 50°C, and monitor the end point of the reaction by HPLC (high performance liquid chromatography). After the reaction was completed, the reaction system was cooled to room temperature, concentrated to dryness under reduced pressure, then dissolved in 100 mL of water, adjusted to the aqueous solution with hydrochloric acid and maintained at an acidic environment with pH<7, then extracted with ethyl acetate, and collected the organic layer, concentrated to dryness to obtain 8.2 g of crude product.

[0033] The crude product was purified by silica gel column (eluent: dichloromethane / methanol = 15:1), traced by TLC, collected product points, and concentrated to dryness to obtain an oily substance. Add 10 mL of acetone and 50 mL of diethyl ether...

Embodiment 2

[0039] The preparation method of embodiment 2 tiagabine ethyl ester hydrochloride

[0040] Dissolve 10g of tiagabine hydrochloride finished product in 50mL of ethanol, add 6mL of concentrated hydrochloric acid dropwise, heat the reaction at 70°C, and monitor the end point of the reaction by HPLC (high performance liquid chromatography). After the reaction was completed, the reaction system was cooled to room temperature, concentrated to dryness under reduced pressure, then dissolved in 100 mL of water, adjusted to the aqueous solution with hydrochloric acid and maintained at an acidic environment with pH<7, then extracted with ethyl acetate, and collected the organic layer, concentrated to dryness to obtain 8.3 g of crude product.

[0041] The crude product was purified by silica gel column (eluent: dichloromethane / methanol = 15:1), traced by TLC, collected product points, and concentrated to dryness to obtain an oily substance. Add 30 mL of ethanol to the obtained oil, heat ...

Embodiment 3

[0042] The preparation method of embodiment 3 tiagabine ethyl ester hydrochloride

[0043] Dissolve 10g of tiagabine hydrochloride finished product in 100mL of ethanol, add 15mL of concentrated hydrochloric acid dropwise, heat the reaction at 70°C, and monitor the end point of the reaction by HPLC (high performance liquid chromatography). After the reaction was completed, the reaction system was cooled to room temperature, concentrated to dryness under reduced pressure, then dissolved in 100 mL of water, adjusted to the aqueous solution with hydrochloric acid and maintained at an acidic environment with pH<7, then extracted with ethyl acetate, and collected the organic layer, washed with 30 mL of saturated NaCl×3, dried over anhydrous sodium sulfate, filtered, and concentrated to dryness to obtain 8.3 g of crude product.

[0044] The crude product was purified by a silica gel column (eluent: dichloromethane / methanol = 10:1), traced by thin layer, collected product points, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com