Long glass fiber composite polyoxymethylene composite material and preparation method thereof

A technology of polyoxymethylene and composite materials, which is applied in the field of long glass fiber composite polyoxymethylene composite materials and its preparation, can solve the problems of narrow processing range, poor thermal stability, and poor dispersion of glass fibers, etc., and achieve Wide processing range, improved mechanical properties, and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

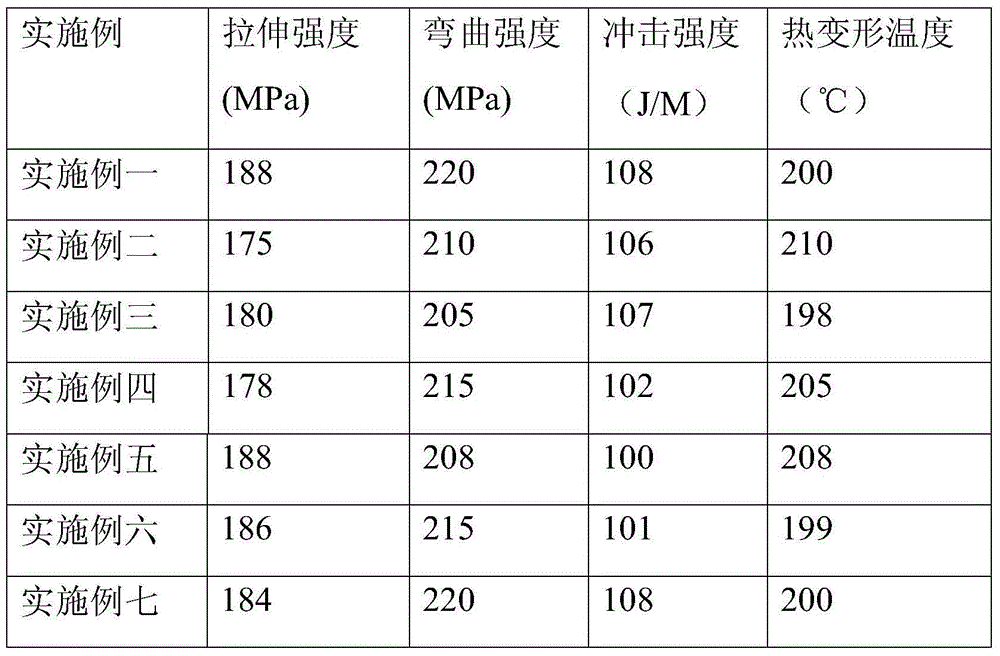

Examples

Embodiment 1

[0021] In the composite material of long glass fiber compounded with polyoxymethylene in this embodiment, the raw materials of the composite material are composed of the following components in parts by weight: 100 parts of polyoxymethylene, 0.4 part of stabilizer, 0.6 part of absorbent, and toughening agent 3 parts, 2 parts of compatibilizer, 0.3 parts of lubricant, 8 parts of filler, 20 parts of high-strength long glass fiber;

[0022] The absorbent is a polyoxymethylene absorbent, and its raw materials include, by weight, 25 parts of glycerol, 0.1 part of phosphoric acid, and 50 parts of hydroxyethyl cellulose.

[0023] In this embodiment, the polyoxymethylene is extrusion-grade copolymerized polyoxymethylene.

[0024] In this embodiment, the stabilizer is potassium iodide. In this embodiment, potassium iodide is replaced by copper bromide, sodium bromide, aromatic amines in organic antioxidant stabilizers, and phenolic antioxidants in equal parts by weight. one, or replac...

Embodiment 2

[0036] The composite material of long glass fiber compounded with polyoxymethylene in this embodiment, the raw material of the composite material consists of the following components in parts by weight: 100 parts of polyoxymethylene, 0.3 part of stabilizer, 0.4 part of absorbent, toughening agent 1 part, 1 part of compatibilizer, 0.1 part of lubricant, 5 parts of filler, 10 parts of high-strength long glass fiber;

[0037] The absorbent is a polyoxymethylene absorbent, and its raw materials include, by weight, 20 parts of glycerol, 0.08 parts of phosphoric acid, and 40 parts of hydroxyethyl cellulose.

[0038] In this embodiment, the polyoxymethylene is extrusion-grade copolymerized polyoxymethylene.

[0039] In this embodiment, the stabilizer is copper bromide. In this embodiment, copper bromide is replaced by potassium iodide, sodium bromide, aromatic amines in organic antioxidant stabilizers, phenolic antioxidant One of the additives, or replace it with a mixture of copper...

Embodiment 3

[0051] The composite material of long glass fiber compounded with polyoxymethylene in this embodiment, the raw material of the composite material is composed of the following components in parts by weight: 100 parts of polyoxymethylene, 0.5 part of stabilizer, 0.8 part of absorbent, and toughening agent 5 parts, 3 parts of compatibilizer, 0.5 parts of lubricant, 10 parts of filler, 30 parts of high-strength long glass fiber;

[0052] The absorbent is a polyoxymethylene absorbent, and its raw materials include, by weight, 30 parts of glycerol, 0.12 parts of phosphoric acid, and 60 parts of hydroxyethyl cellulose.

[0053] In this embodiment, the polyoxymethylene is extrusion-grade copolymerized polyoxymethylene.

[0054] In this embodiment, the stabilizer is sodium bromide. In this embodiment, sodium bromide is replaced by copper bromide, potassium iodide, aromatic amines and phenolic antioxidants in organic antioxidant stabilizers according to the same weight. One of the addi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com