Pd/SiO2 catalyst and preparation method and application thereof

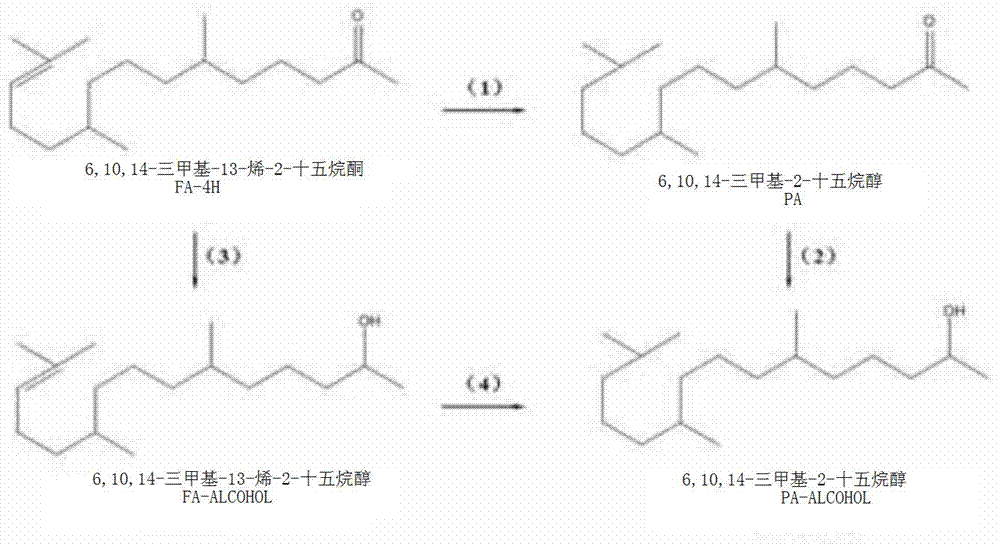

A catalyst and co-catalyst technology, applied in the direction of physical/chemical process catalysts, carbon-based compound preparation, chemical instruments and methods, etc., can solve problems such as difficult to obtain, high reactivity, etc., to reduce residence time, improve selectivity, Overcoming the effect of intermittent liquid phase hydrogenation process production operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

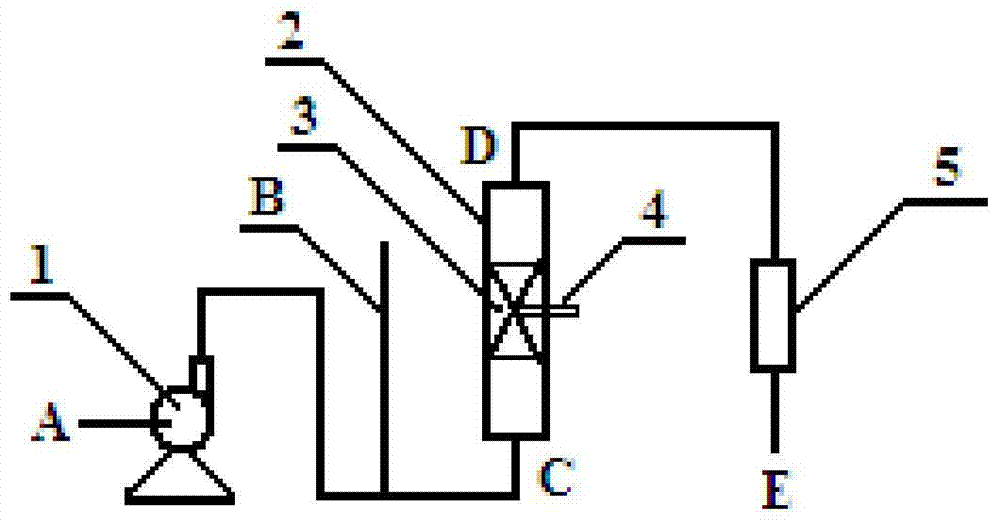

Method used

Image

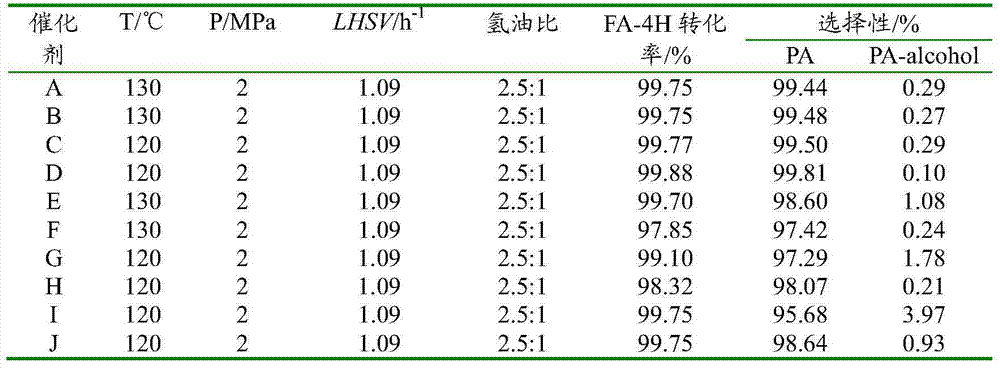

Examples

Embodiment 1

[0040] Add 0.52ml of palladium chloride-hydrochloric acid solution (palladium chloride concentration of 0.08g / ml) to 50ml of deionized water, then add 1.5g of citric acid, wait for it to dissolve, and mix with the palladium chloride-hydrochloric acid solution. Pour 25g of 6-8 mesh spherical silica gel particles into it and soak for 2 hours. The above mixture was dried on a rotary evaporator at 50°C and 0.09MPa for 3 hours, and then at 80°C and 0.09MPa for 2 hours. The dried catalyst was calcined in a muffle furnace at 400° C. for 3 hours to obtain catalyst A. The weight content of metal Pd is 0.1%, and the rest is silica gel support; the obtained catalyst is spherical particles of 6-8 mesh, the average particle strength is 8.3Kg / particle; its specific surface area is 213.5m 2 / g, the most probable pore diameter is 19.6nm, and the pore volume is 1.01ml / g.

Embodiment 2

[0042] The preparation method of catalyst B is the same as that of Example 1, but the carrier used is 6-8 mesh block silica gel particles. The weight content of the metal Pd is 0.1%, and the rest is silica gel support; the obtained catalyst is 6-8 mesh block particles, the average particle strength is 3.1Kg / particle; its specific surface area is 166.2m 2 / g, the most probable pore size is 23.4nm, and the pore volume is 0.98ml / g.

Embodiment 3

[0044] Add 1.56ml of palladium chloride-hydrochloric acid solution (palladium chloride concentration of 0.08g / ml) to 50ml of deionized water, then add 1.5g of ethylenediamine, wait for it to dissolve, and mix with the palladium chloride-hydrochloric acid solution, Pour 25g of 6-8 mesh lumpy silica gel particles into it and soak for 2 hours. The above mixture was dried on a rotary evaporator at 50°C and 0.09MPa for 1 hour, and then at 80°C and 0.09MPa for 2 hours. The dried catalyst was calcined in a muffle furnace at 400°C for 3 hours to obtain catalyst C. The weight content of metal Pd is 0.5%, and the rest is silica gel support; the obtained catalyst is spherical particles of 6-8 mesh, the average particle strength is 4.0Kg / particle; its specific surface area is 220.1m 2 / g, the most probable pore diameter is 18.6nm, and the pore volume is 0.97ml / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Most probable aperture | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com