Aluminum alloy direct current plasma-tungsten electrode argon arc hybrid welding method based on pulse coordination control

A tungsten argon arc welding and tungsten argon arc technology, applied in the field of aluminum alloy welding, can solve the problems of low effective thermal power, affecting welding quality and efficiency, and rapid electrode burning, achieving good arc stability and ensuring welding seam. The effect of forming quality and low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

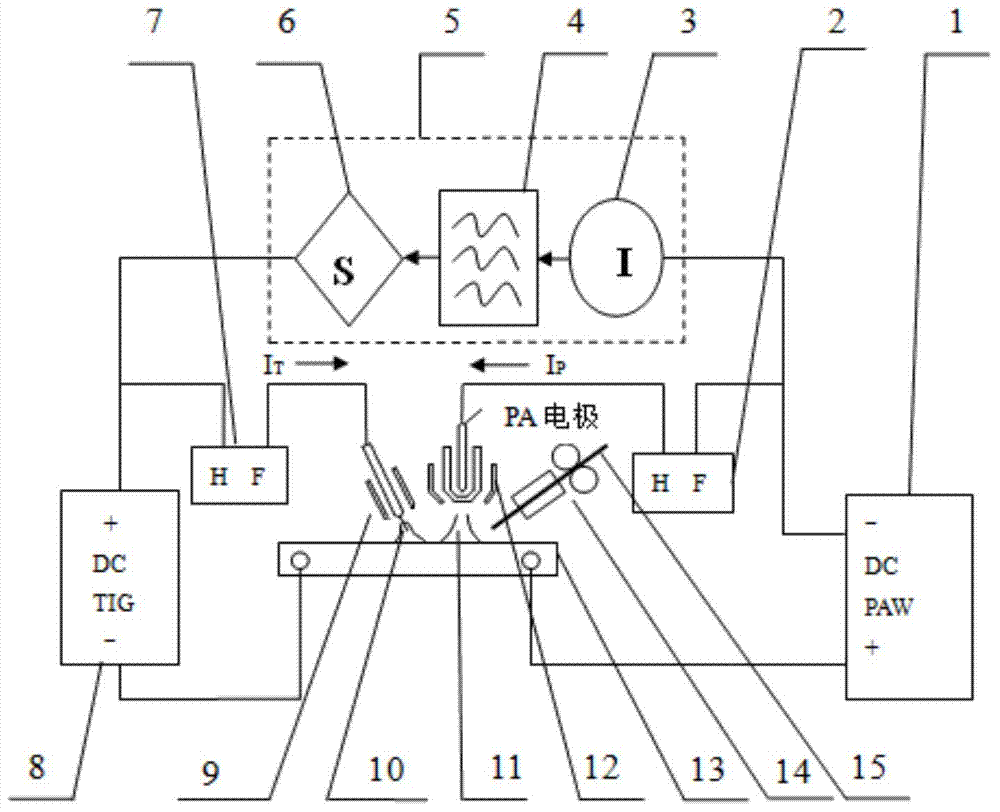

[0030] combine figure 1 , which is based on the implementation of pulse-coordinated aluminum alloy DC plasma-reverse connection argon tungsten arc composite welding device. , wire feeder 14, high-frequency arc starter 2 and 7, current signal detector 3, signal processor (PLC or single-chip microcomputer) 4, signal controller 6 and so on. During welding, the argon tungsten arc welding torch 9 and the filler wire 15 can be placed on both the front and rear sides of the plasma torch 12, and can also be placed on the left and right sides of the plasma torch 12 to form a combined plasma-argon tungsten arc welding joint. During the welding process, the current pulse flowing through the plasma arc is detected by the current signal detector 3, and the current pulse of the DC reverse connection tungsten argon arc welding is adjusted through the signal processor 4 and the controller 6, thereby adjusting the oxide film on the surface of the aluminum alloy. The degree of cleaning can be ...

specific Embodiment approach 2

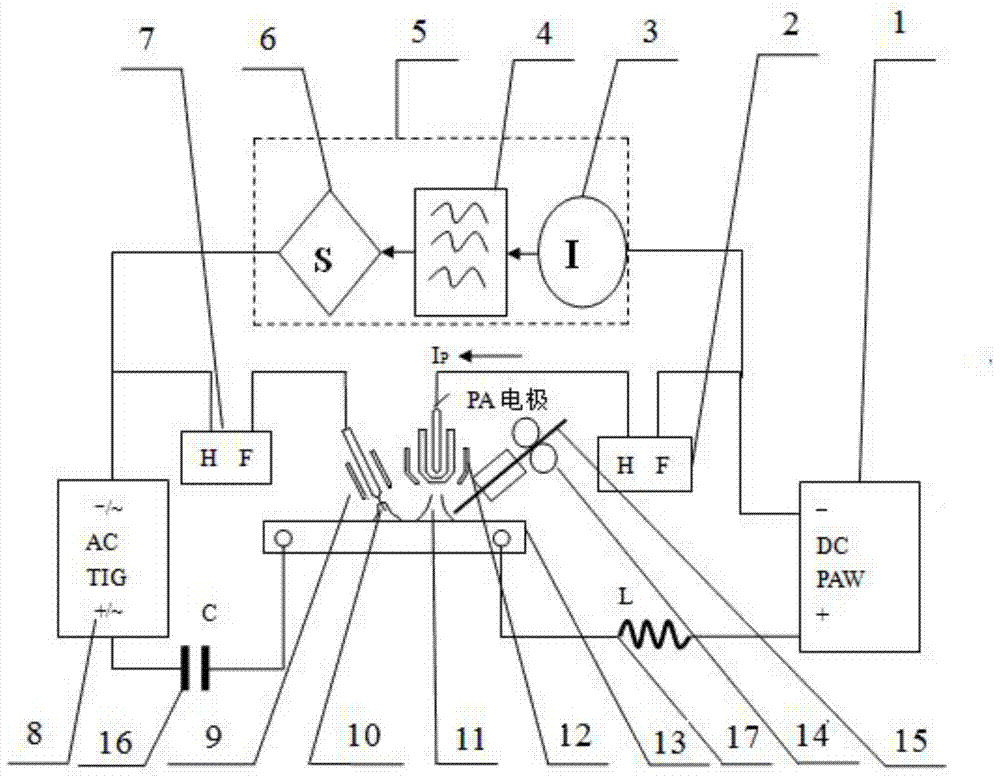

[0037] combine figure 2 , it is based on the implementation of the pulse-coordinated aluminum alloy DC plasma-AC tungsten arc composite welding device. Composed of high-frequency arc starters 2 and 7, current signal detector 3, signal processor 4 (PLC or single-chip microcomputer), signal controller 6, control system 5, capacitor 9, inductor 15, wire feeder 16, etc. During welding, the argon tungsten arc welding torch 10 and the filler wire 17 can be placed on both the front and rear sides of the plasma torch 13, and can also be placed on the left and right sides of the plasma torch 13 to form a plasma-tungsten argon arc composite welding joint. During the welding process, the current pulse flowing through the plasma arc is detected by the current signal detector 3, and the current pulse of the argon tungsten arc is adjusted through the signal processor 4 and the controller 6, thereby adjusting the oxide film cleaning degree of the argon tungsten arc , by changing the peak p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com