Equipment for preparing hydrogen from methanol and water

A hydrogen production equipment, methanol water technology, applied in the direction of hydrogen, inorganic chemistry, non-metallic elements, etc., can solve the problems of not easy to carry, increase the volume of equipment, burn people, etc., to reduce the cost of hydrogen production, reduce the volume of equipment, improve The effect of mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

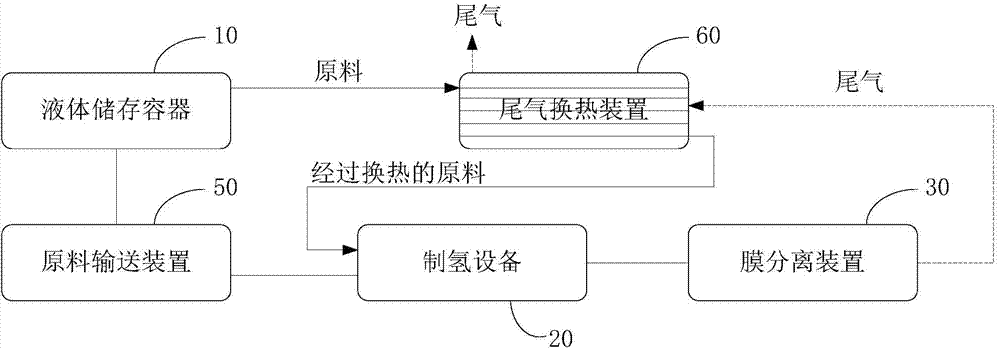

[0055] see figure 1 The present invention discloses a device for preparing hydrogen by using methanol water. The liquid storage container 10 is used to store liquid methanol and water, and the raw material transport device 50 transports the methanol and water raw materials in the liquid storage container 10 to the hydrogen production equipment 20 to prepare hydrogen, and the prepared hydrogen is transported to the membrane separation device. 30 to separate.

[0056] The exhaust heat exchange device 60 includes a second heat exchanger, and the second heat exchanger uses raw methanol and water as the cooling medium to cool the exhaust gas; the inlet of the heat exchange tube of the second heat exchanger is connected to the liquid storage container through a pipeline, and the first heat exchanger is connected to the liquid storage container. The outlet of the heat exchange tube of the second heat exchanger is connected to the hydrogen production equipment 20; the heat exchange o...

Embodiment 2

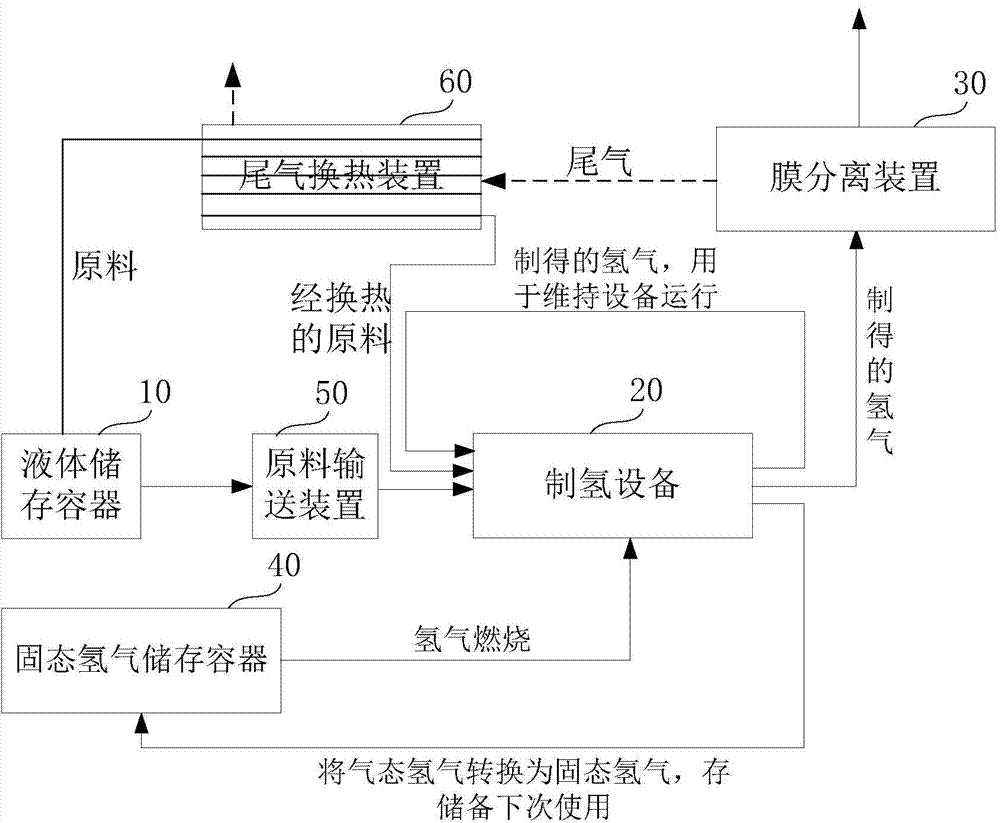

[0060] The difference between this embodiment and Embodiment 1 is that in this embodiment, please refer to image 3 The equipment for preparing hydrogen uses methanol water to prepare hydrogen, and the equipment for preparing hydrogen includes a solid hydrogen storage container 40, a liquid storage container 10, a raw material conveying device 50, a hydrogen production equipment 20, a membrane separation device 30, and a tail gas heat exchange device. 60. The exhaust heat exchange device 60 is similar to that of the first embodiment.

[0061] The solid hydrogen storage container 40 and the liquid storage container 10 are respectively connected to the hydrogen production equipment 20; the liquid storage container 10 stores liquid methanol and water, and the solid hydrogen storage container 40 stores solid hydrogen.

[0062] When the hydrogen production system is started, the solid hydrogen in the solid hydrogen storage container 40 is converted into gaseous hydrogen by the gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com