Preparation method of graphene powder material

A technology of graphene powder and bulk material, applied in the field of graphene, can solve the problems of low concentration of graphene dispersion, limited application of graphene, incomplete reduction, etc., and achieve the effects of short cycle, mild reaction conditions and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

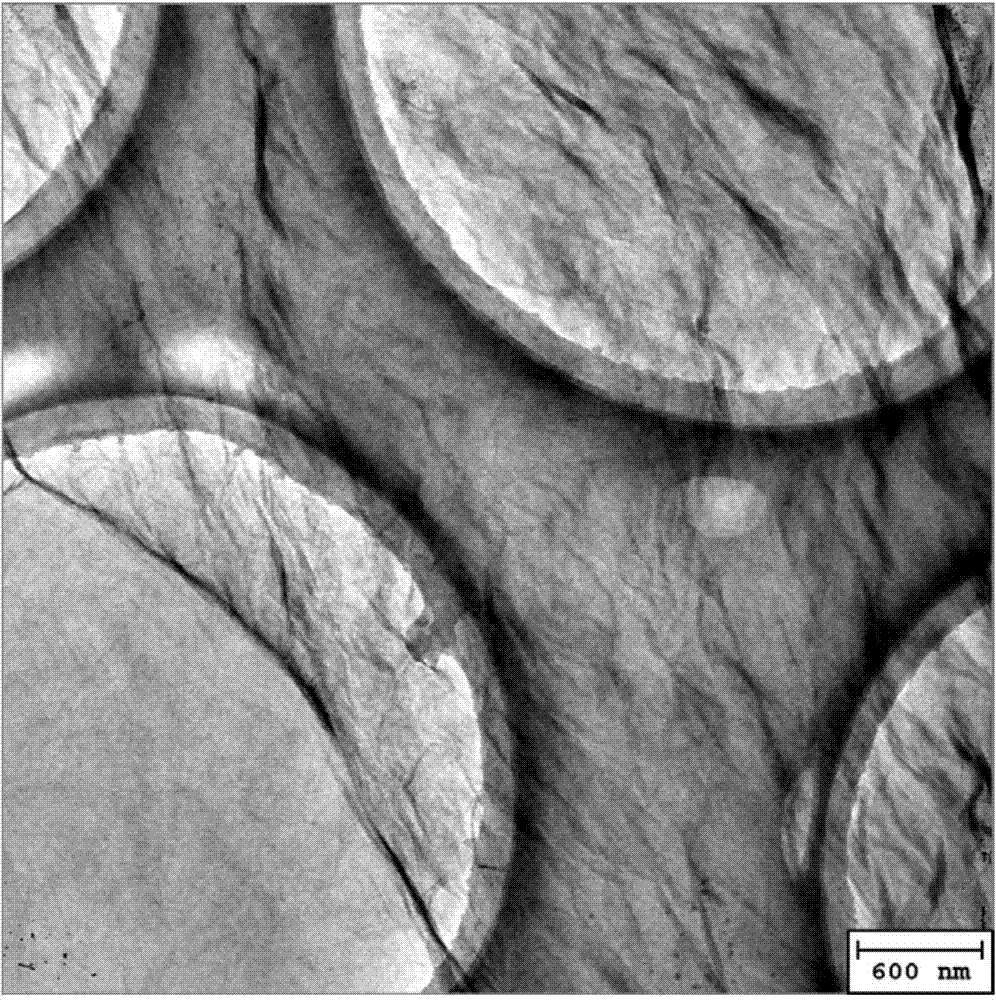

[0037] The preparation method of the graphene powder material of the present embodiment comprises the following steps:

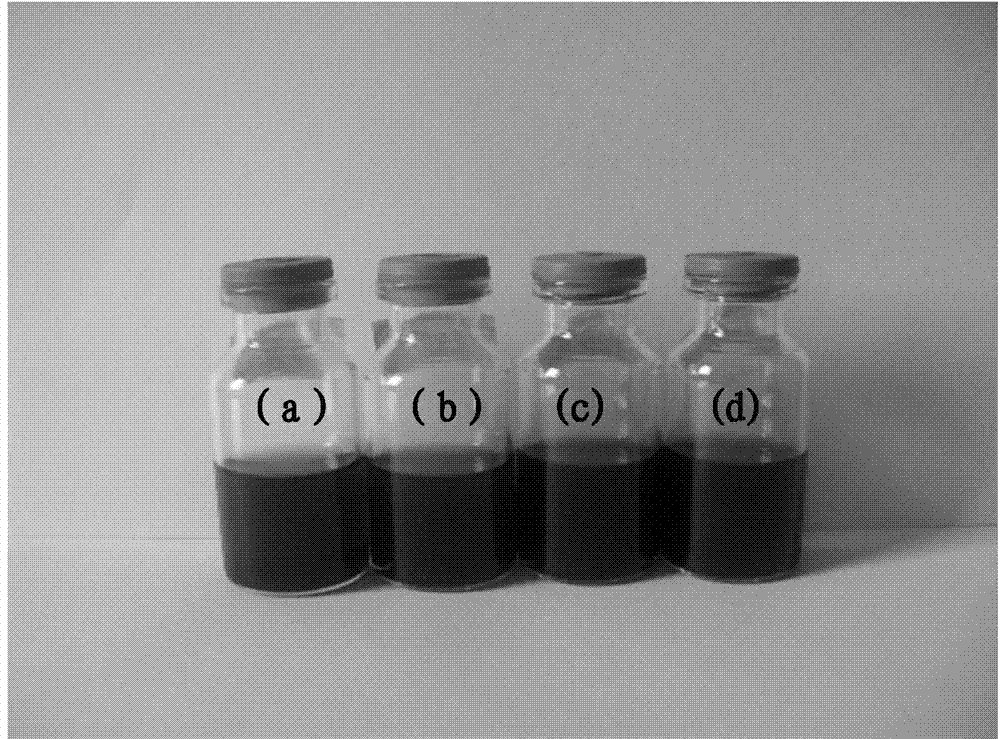

[0038] 1) Add 1g of graphite oxide into 50ml of tetramethylammonium hydroxide solution with a mass concentration of 10%, and disperse it by ultrasonic, with an ultrasonic power of 400W and an ultrasonic time of 60min, to obtain a graphene dispersion;

[0039] 2) Add 5ml of tetramethylammonium borohydride to the graphene dispersion obtained in step 1), stir for 3 hours at room temperature, filter through a 0.45 μm microporous membrane, and freeze-dry at -20°C. The drying time is 10 hours, and the graphene powder material is obtained.

Embodiment 2

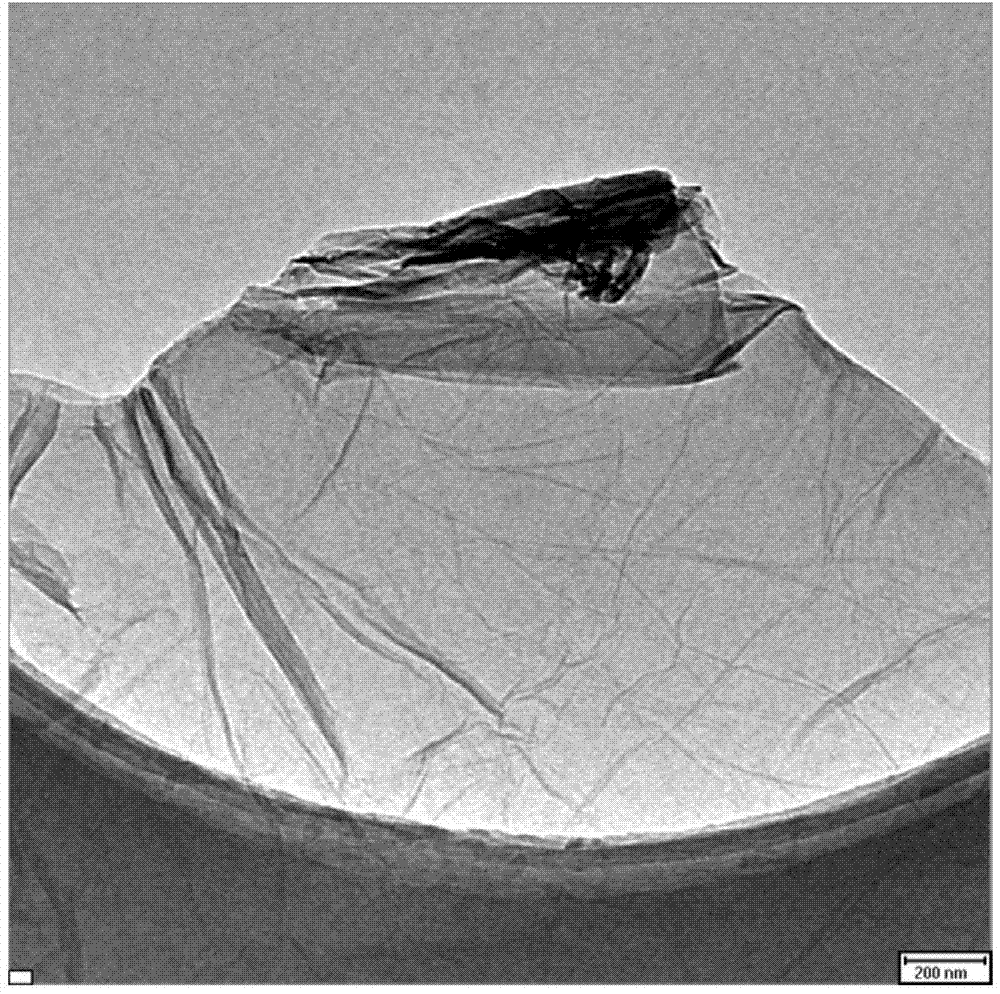

[0041] The preparation method of the graphene powder material of the present embodiment comprises the following steps:

[0042] 1) Add 1g of graphite oxide into 50ml of tetraethylammonium hydroxide solution with a mass concentration of 20%, and disperse it by ultrasonic, with an ultrasonic power of 300W and an ultrasonic time of 60min, to obtain a graphene dispersion;

[0043] 2) Add 5ml of tetraethylammonium borohydride to the graphene dispersion obtained in step 1), stir for 3 hours at room temperature, filter through a 0.1 μm microporous membrane, and freeze-dry at -10°C. The drying time is 24 hours, and the graphene powder material is obtained.

Embodiment 3

[0045] The preparation method of the graphene powder material of the present embodiment comprises the following steps:

[0046] 1) Add 1g of graphite oxide into 50ml of tetrapropylammonium hydroxide solution with a mass concentration of 30%, and ultrasonically disperse it with an ultrasonic power of 200W and an ultrasonic time of 60min to obtain a graphene dispersion;

[0047] 2) Add 5ml of tetrapropylammonium borohydride to the graphene dispersion obtained in step 1), stir for 3 hours at room temperature, filter through a 0.22 μm microporous membrane, and freeze-dry at -5°C. The drying time is 48h, and the graphene powder material is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com