Preparation method of laser protective film for identification card

A protective film and laser technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve problems affecting applicability and complicated manufacturing processes, and achieve the effects of simplified manufacturing processes, stable chemical properties, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

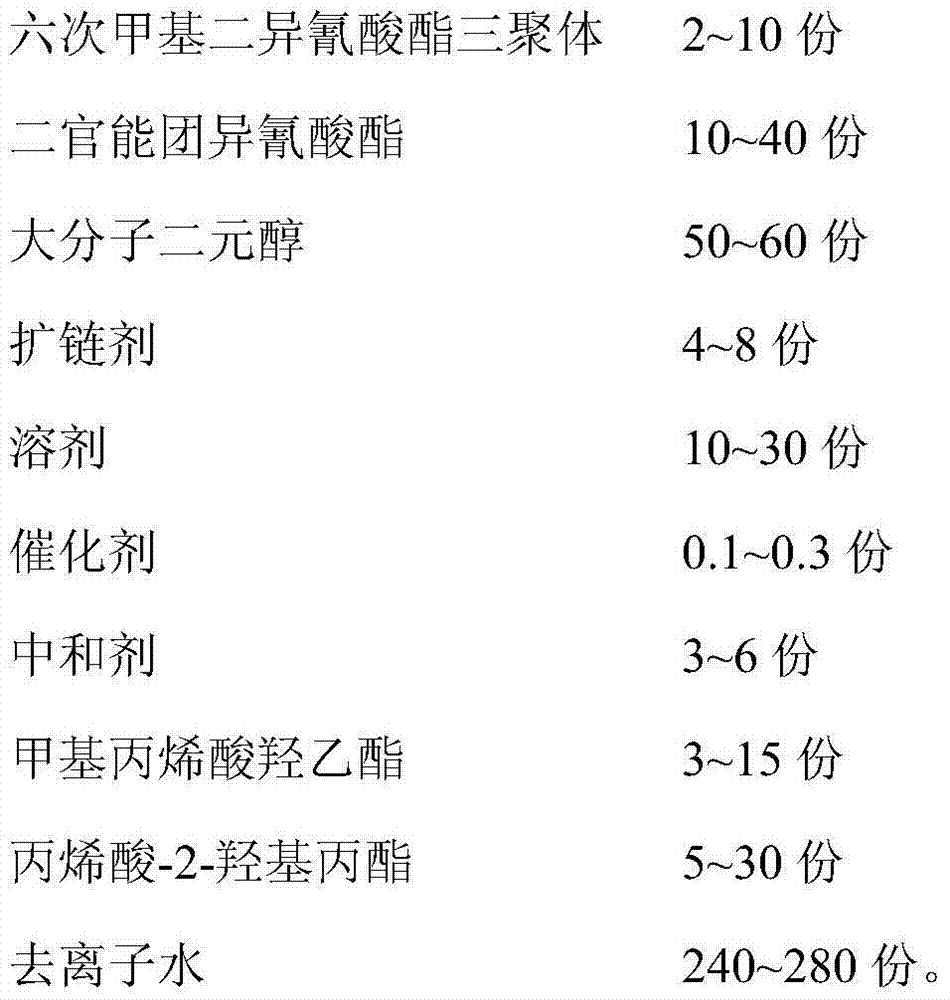

[0029] A kind of laser protection film for card, the laser protection film is composed of a base material and a laser coating, and the laser coating is partially or completely coated on the base material, wherein the base material is made of polyvinyl chloride, polyparaffin It is prepared from ethylene glycol phthalate, polycarbonate or polyethylene terephthalate-1,4-cyclohexanedimethanol, and the components and weights of the raw materials required for laser coating are respectively :

[0030]

[0031] The above-mentioned macromolecular diol is: poly-1,6-adipate-1,4-butylene glycol ester diol with a molecular weight of 4000-7000.

[0032] The preparation method step of above-mentioned laser coating is:

[0033] (1) Add trifunctional isocyanate, difunctional isocyanate, macromolecular diol, chain extender, solvent and catalyst into a reaction vessel equipped with a thermometer, agitator and reflux condenser, mix well, and control the temperature under an inert gas enviro...

Embodiment 2

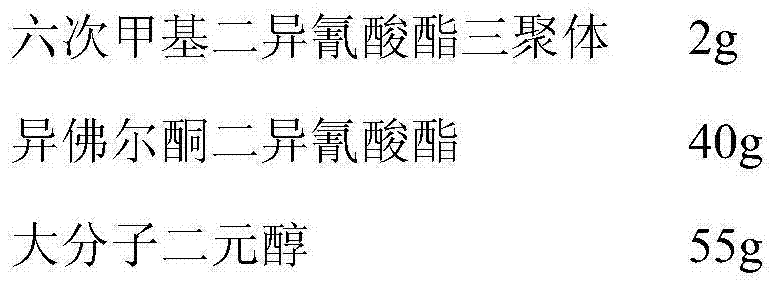

[0043] A kind of laser protection film for card, the laser protection film is composed of a base material and a laser coating, and the laser coating is partially or completely coated on the base material, wherein the base material is made of polyvinyl chloride, polyparaffin It is prepared from ethylene glycol phthalate, polycarbonate or polyethylene terephthalate-1,4-cyclohexanedimethanol, and the components and weights of the raw materials required for laser coating are respectively :

[0044] The above-mentioned macromolecular diol is: polycaprolactone diol with a molecular weight of 4000-7000.

[0045] The steps of the preparation method of the above-mentioned laser coating are the same as those in Example 1, and the thickness of the card protection film is 0.03mm.

[0046] The preparation method of the above-mentioned laser protection film is the same as that in Example 1.

[0047] The lamination method of the above-mentioned laser protection film and the card core lay...

Embodiment 3

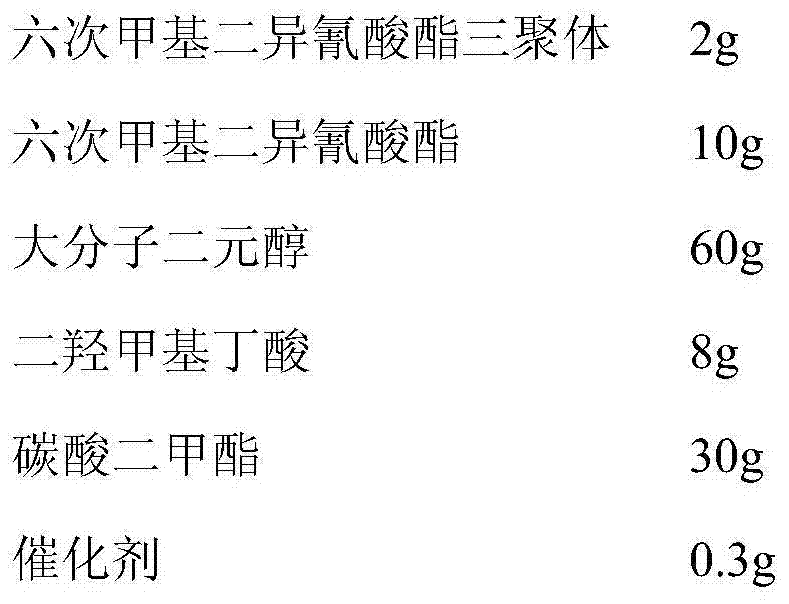

[0049]A kind of laser protection film for card, the laser protection film is composed of a base material and a laser coating, and the laser coating is partially or completely coated on the base material, wherein the base material is made of polyvinyl chloride, polyparaffin It is prepared from ethylene glycol phthalate, polycarbonate or polyethylene terephthalate-1,4-cyclohexanedimethanol, and the components and weights of the raw materials required for laser coating are respectively :

[0050]

[0051] The above-mentioned macromolecular diol is: poly-1,6-hexanediol ester diol with a molecular weight of 4000-7000.

[0052] The steps of the preparation method of the above-mentioned laser coating are the same as those in Example 1, and the thickness of the card protection film is 0.1 mm.

[0053] The preparation method of the above-mentioned laser protection film is the same as that in Example 1.

[0054] The lamination method of the above-mentioned laser protection film a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com