Anode material for lithium-air battery and preparation method thereof

A lithium-air battery and cathode material technology, which is applied in battery electrodes, fuel cell-type half-cells and secondary battery-type half-cells, circuits, etc. Graphene preparation process is complicated and other problems, to achieve the effect of low price, high specific capacity and abundant sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

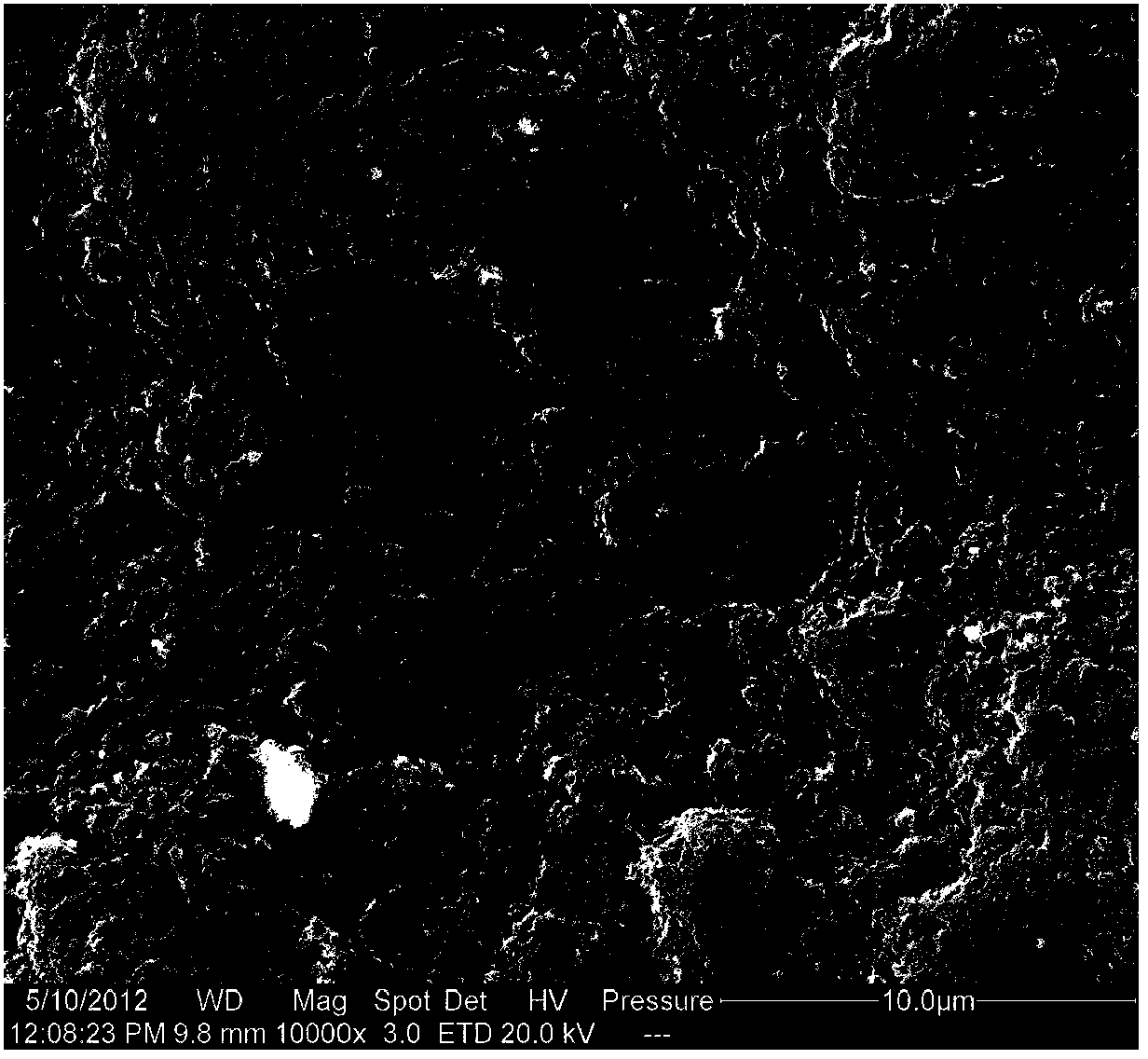

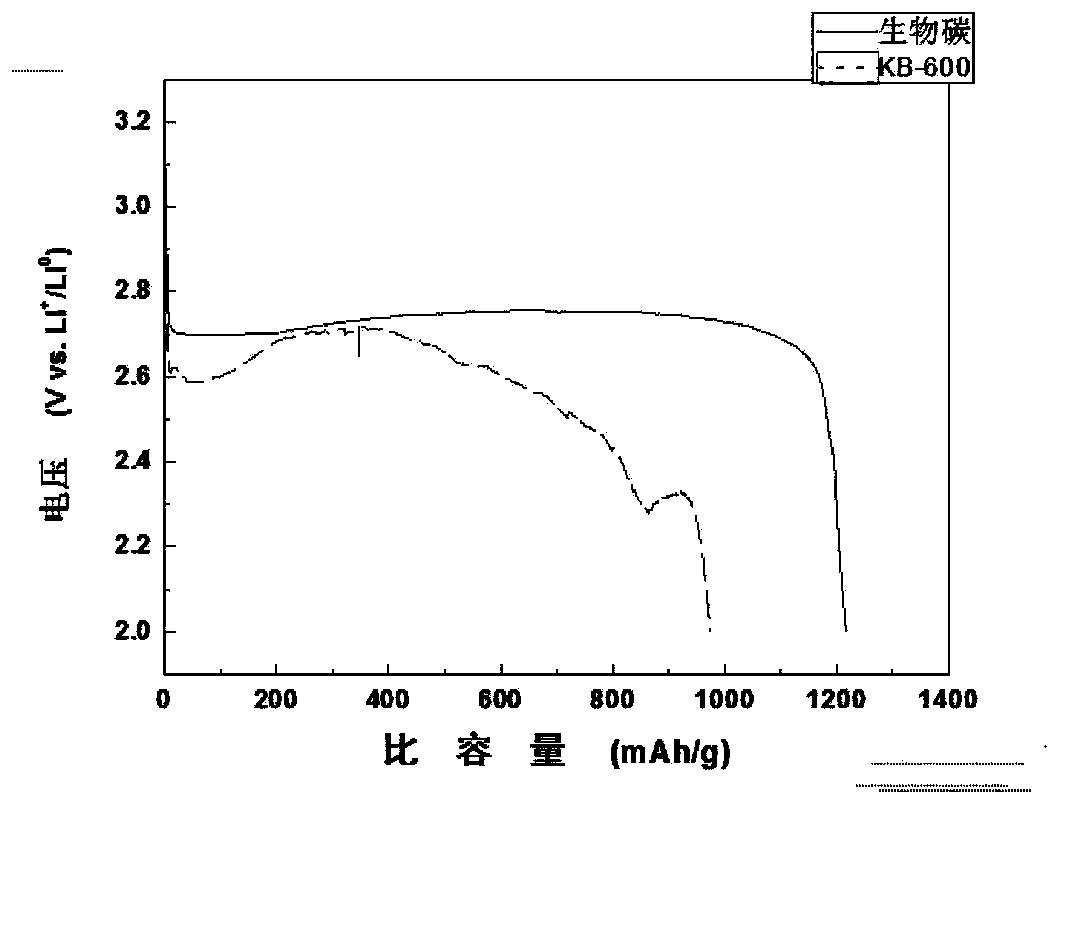

[0030] Wash, dry and pulverize the biomass raw material Chinese fir sawdust and pass it through a 50-mesh sieve, and take the part under the sieve. The fir sawdust was soaked in 10wt% KOH solution for 24 hours according to the alkali-carbon ratio of 4:1, and dried at 60°C to remove water. Put the impregnated Chinese fir sawdust in the crucible furnace, under N 2 Sinter at 800°C for 2h in the atmosphere, wash with water, and dry at 60°C; take 10g of the carbonized sample and dip it in 100mL of 2% ferric nitrate solution for 24h, dry it and place it in a tube furnace under N 2 The temperature was raised to 900°C under the atmosphere, and CO 2 Gas activation 1h, CO 2 The gas flow rate is 50mL.min -1 . Such as figure 1 The shown biochar cathode has a certain pore structure that can accommodate insoluble lithium peroxide generated during discharge. figure 2 The lithium-air battery assembled with the positive electrode material of the present invention exhibits a large specif...

Embodiment 2

[0032] Ginkgo biloba shells are washed, dried, crushed and passed through a 50-mesh sieve. Ginkgo shells were soaked in 15wt% NaOH solution for 24 hours according to the alkali-carbon ratio of 2:1, and then filtered and dried. Carbonize the impregnated ginkgo shells in a crucible furnace at 800°C for 2h under Ar atmosphere, weigh 10g of carbonized material, dip in 100ml of 3% iridium nitrate solution for 36h, filter and dry, activate in a tube furnace at 800°C 2h, the activation gas is water vapor, the gas flow rate is 50mL.min -1 .

Embodiment 3

[0034] The corncobs are washed, dried and crushed and passed through a 50-mesh sieve. Immerse corncobs in 10wt% KOH solution for 24 hours according to the alkali-carbon ratio of 4:1, filter and dry them, place them in a crucible furnace, and carbonize them at 700°C for 2 hours under an Ar atmosphere. Immerse in nickel solution for 48 hours, filter and dry, then place in a tube furnace at 900°C CO 2 Activated for 1h under the condition of activated gas, CO 2 The flow rate is 70mL.min -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com