A high-performance PE cling film for automatic packaging machines

An automatic packaging machine, high-performance technology, applied in packaging, wrapping paper, transportation and packaging, etc., can solve the problem of PE cling film flexibility, shrinkage adhesiveness, transparency, poor surface gloss, uneven film surface, The film body is easy to break and other problems, to achieve the effect of improving fresh-keeping effect, improving gloss, and excellent flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

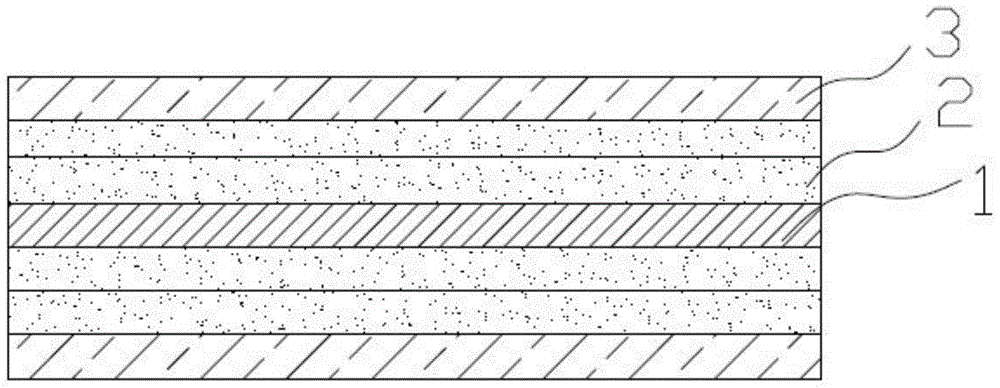

[0024] Such as figure 1 A PE fresh-keeping film for an automatic packaging machine is shown, which includes a core layer 1 with a thickness of 10 μm. The upper and lower surfaces of the core layer 1 are respectively provided with two intermediate layers 2 each with a thickness of 10 μm, which are located on the core layer 1. The upper surface of the uppermost middle layer 2 and the lower surface of the lowermost middle layer 2 located on the lower surface of the core layer 1 are provided with a surface layer 3 with a thickness of 2 μm, the core layer 1 and the middle layer 2, the middle layer 2 and the middle layer 2 , The middle layer 2 and the surface layer 3 are extruded by a single-screw extruder and then cast into an integrated film structure, wherein the core layer 1 is composed of LLDPE and mLLDP (mass ratio 1:4), POE, Anti-fogging agent, stearic acid and cellulose are mixed. The middle layer 2 is made of LLDPE and mLLDPE (mass ratio 1:1), POE, anti-fogging agent and ce...

Embodiment 2

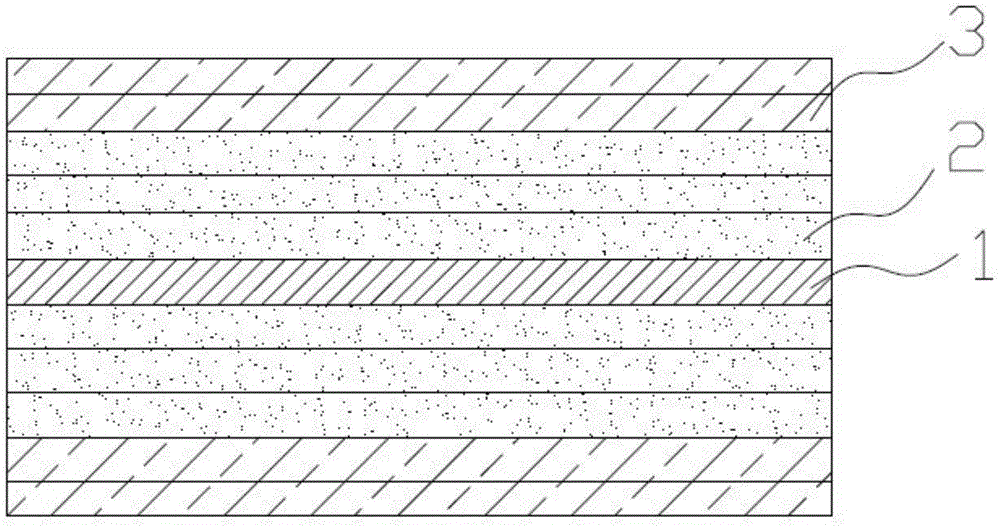

[0026] Such as figure 1 A PE fresh-keeping film for an automatic packaging machine as shown, including a core layer 1 with a thickness of 2 μm, the upper and lower surfaces of the core layer 1 are respectively provided with two intermediate layers 2 each with a thickness of 2 μm, located on the core layer 1 The upper surface of the uppermost middle layer 2 and the lower surface of the lowermost middle layer 2 located on the lower surface of the core layer 1 are provided with a surface layer 3 with a thickness of 2 μm, the core layer 1 and the middle layer 2, the middle layer 2 and the middle layer 2 , The middle layer 2 and the surface layer 3 are extruded by a single-screw extruder and then cast into an integrated film structure, wherein the core layer 1 is composed of mLLDPE, POE, anti-fogging agent, stearic acid and fiber The middle layer 2 is made by mixing mLLDPE, POE, anti-fogging agent and cellulose according to the mass percentage, and the surface layer 3 is composed o...

Embodiment 3

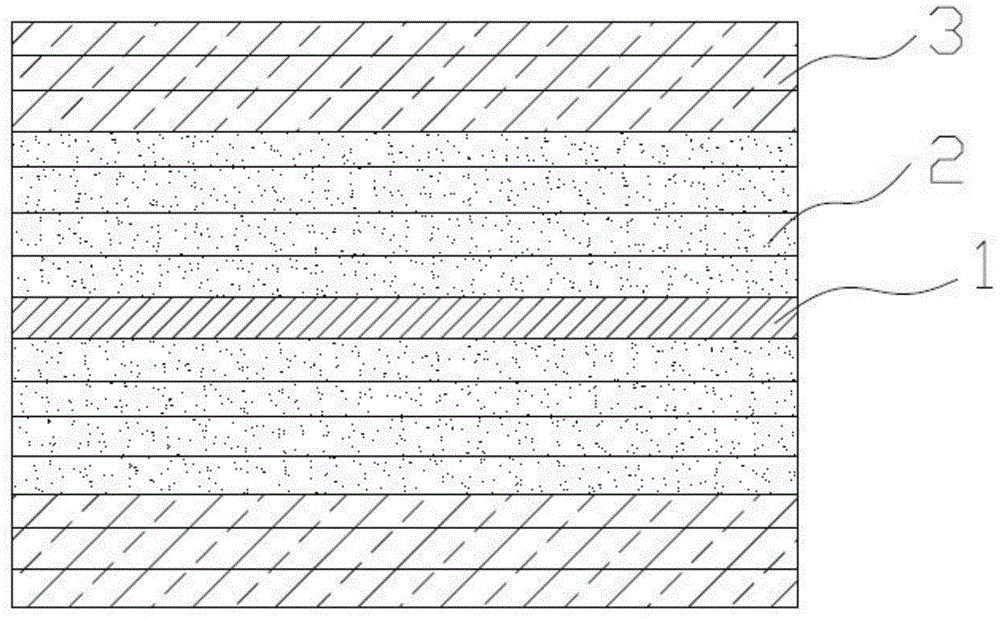

[0028] Such as image 3 A PE fresh-keeping film for an automatic packaging machine as shown, including a core layer 1 with a thickness of 2 μm, the upper and lower surfaces of the core layer 1 are respectively provided with two intermediate layers 2 each with a thickness of 2 μm, located on the core layer 1 The upper surface of the uppermost middle layer 2 and the lower surface of the lowermost middle layer 2 located on the lower surface of the core layer 1 are provided with a surface layer 3 with a thickness of 2 μm, the core layer 1 and the middle layer 2, the middle layer 2 and the middle layer 2 , The middle layer 2 and the surface layer 3 are extruded by a single-screw extruder and then cast into an integrated film structure, wherein the core layer 1 is composed of mLLDPE, POE, anti-fogging agent, stearic acid and fiber The middle layer 2 is made by mixing LLDPE, POE, anti-fogging agent and cellulose according to the mass percentage, and the surface layer 3 is composed of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com