Method for enhancing gold precipitation grade in gold electrorefining process

An electrolytic refining and crafting technology, which is applied in the field of gold electrolytic refining, can solve the problem of low gold precipitation and other problems, and achieve the effects of strong corrosion resistance to hydrochloric acid, stability assurance, and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

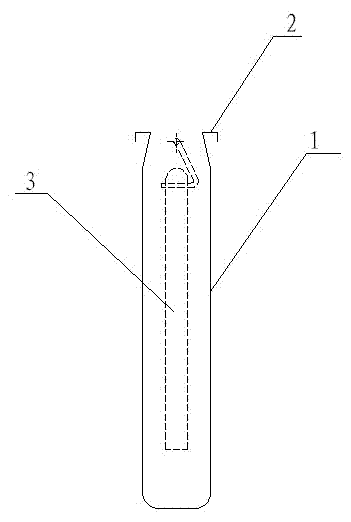

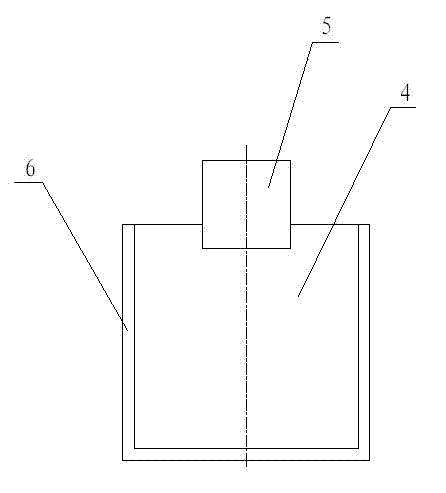

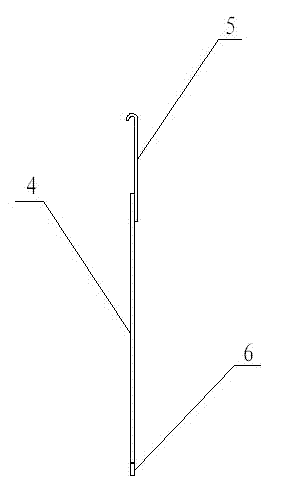

[0020] A method for improving the gold precipitation grade in a gold electrolytic refining process, using crude gold as an anode, pure gold as a cathode, and gold trichloride solution as an electrolyte for electrolytic refining; figure 1 As shown, wherein, the outside of the anode plate 3 made of coarse gold is covered with a pocket-shaped diaphragm 1 made of polypropylene, the mesh of the diaphragm 1 is 800-850 mesh, and the upper opening of the diaphragm 1 is provided with a hook 2 , for fixing the diaphragm 1.

[0021] The technical and economic indicators of the above-mentioned process method are as follows:

[0022] Crude gold grade (mass fraction): Au: 88%—95%

[0023] Cathode grade (mass fraction): Au≥99.996%

[0024] Anode specification: 180×140mm×10mm

[0025] Cathode specification: 180×140mm×0.2mm

[0026] Electrolyte composition: Au:250—350g / L, HCL:150—300 g / L

[0027] Current density: 280—350A / m??

[0028] Electrolyte temperature: 30-40°C

[0029] Electrolyz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com