Preparation method of highly dispersed nanoflake magnesium hydroxide

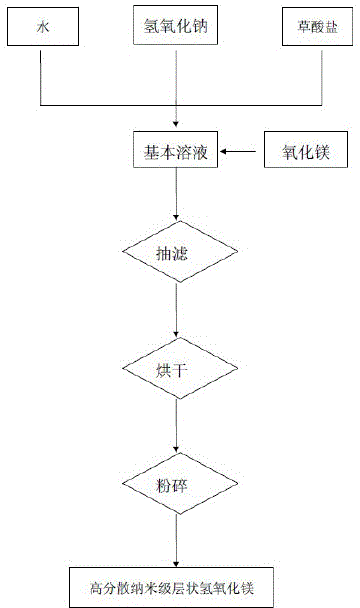

A magnesium hydroxide and nano-flaky technology, which is applied in the field of preparation of highly dispersed nano-flaky magnesium hydroxide, can solve the problems of high equipment requirements and energy consumption, obstacles to industrial production, and cumbersome operations, and achieve low equipment requirements and reduce The effect of production cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

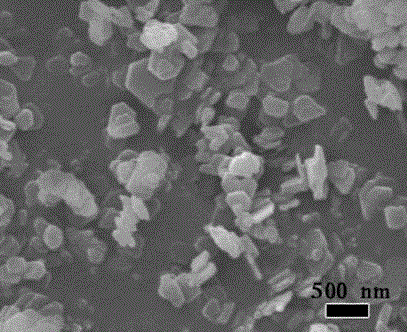

[0015] Weigh 50g of sodium hydroxide and dissolve it in 150g of water to make a sodium hydroxide solution with a mass fraction of 25%, then add 2g of potassium oxalate to dissolve it, stir evenly, transfer to a 500 mL three-necked flask, and heat in a water bath at 90°C After constant temperature, add 20g of magnesium oxide, react for 3h, filter with suction, dry and pulverize to obtain 300 nm particle size and highly dispersed flake magnesium hydroxide. The scanning electron microscope picture is as follows: figure 2 shown.

Embodiment 2

[0017] Weigh 40g of sodium hydroxide and dissolve it in 160g of water to make a sodium hydroxide solution with a mass fraction of 20%, then add 4g of potassium oxalate to dissolve it, stir evenly, transfer to a 500 mL three-necked flask, and heat in a water bath at 80°C , after constant temperature, add 20g of magnesium oxide, react for 3h, filter with suction, dry and pulverize to obtain 300nm particle size and highly dispersed flaky magnesium hydroxide.

Embodiment 3

[0019] Weigh 20g of sodium hydroxide and dissolve it in 180g of water to make a sodium hydroxide solution with a mass fraction of 10%, then add 5g of potassium oxalate to dissolve it, stir evenly, transfer to a 500 mL three-necked flask, and heat in a water bath at 70°C , after constant temperature, add 25g of magnesium oxide, react for 4h, filter with suction, dry and pulverize to obtain flaky magnesium hydroxide with a particle size of 300 nm and high dispersion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com