Groundwater organic pollutant restoration device and method

A technology for organic pollutants and groundwater, applied in the fields of adsorbed water/sewage treatment, reduced water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problems of high maintenance cost, difficult operation, long repair cycle, etc., and achieve easy management. Maintenance, operability, and the effect of reducing repair costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

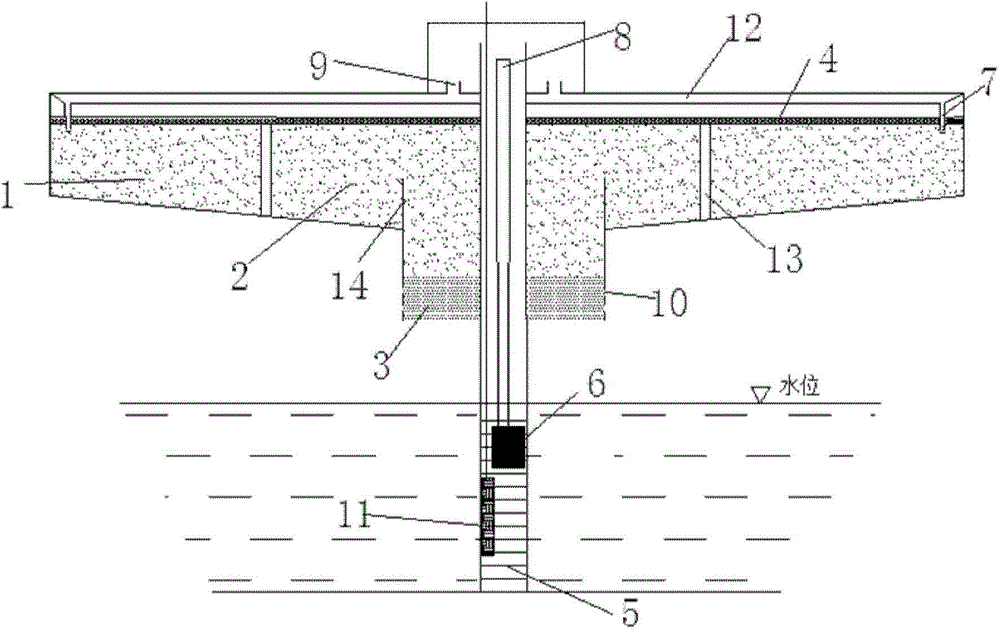

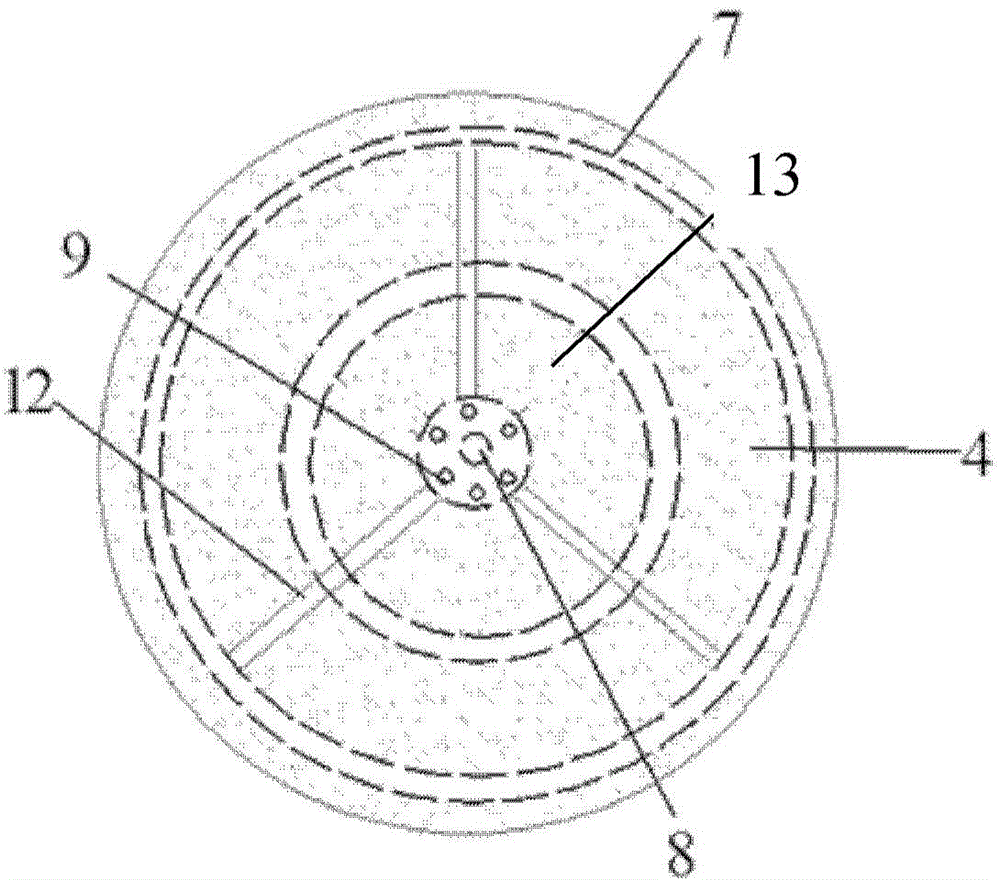

[0049] For the shallow groundwater polluted by nitrobenzene, the buried depth is 3.5m, the thickness of the aquifer is 3-4.5m, and the permeability coefficient is 4.5m / d through micro-water test.

[0050]To construct a groundwater pumping well, the depth of the screen pipe 5 is 4.5m, and its length is 1.5m. Excavate the outer circle with a radius of 3m and a depth of 1.5m; excavate a circle with a radius of 1m at the bottom of the circular pit with a depth of 0.5m. The bottom of the round pit is filled with 30cm of fine sand (particle size 1.6mm-2.2mm) as a fast seepage area, and part of the fine sand is filled with 20cm of small particle size zeolite (particle size 5mm-7mm) and persulfate slow-release material (particle size 6mm ), on this basis, the area with a radius of 1.5m and a height of 1.3m is filled with small particle size zeolite (particle size 5mm-7mm) and persulfate slow-release material (particle size 6mm), and the remaining annular area is filled Reducing mediu...

Embodiment 2

[0052] Choose an abandoned gas station polluted by vinyl chloride, the groundwater depth is about 9m, the aquifer thickness is nearly 6m, and its permeability coefficient is 5.1 / d.

[0053] To build a groundwater pumping well, the depth of the screen pipe is 11m and the length is 3m. Excavate a circular pit with a radius of 4m and a depth of 2m; excavate a circle with a radius of 1.5m and a depth of 4m at the bottom of the circular pit. Anti-seepage is adopted on the sides of the entire pit, and the bottom of the pit is filled with fine sand (particle size 2.0mm-2.8mm) with a height of 3.2m as the fast seepage area, and the upper part of the fast seepage area is filled with 80cm small particle size zeolite (particle size 7mm-9mm) and persulfate slow-release material (particle size 8mm), and then fill the circular area with a radius of 2.5m above the bottom circular pit with small particle size zeolite (particle size 5mm-7mm) and persulfate slow-release material (particle size...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Permeability coefficient | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com