Treatment process of agrochemical high-concentration salt-containing wastewater

A saline wastewater and treatment process technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, alkali metal chloride, etc., can solve problems such as high operating costs, complex salt mixing, and unfavorable treatment. Achieve the effects of saving time and cost, enriching water resources, and high biodegradability

Active Publication Date: 2014-08-20

JINGBO AGROCHEM TECH CO LTD

View PDF8 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0011] With the rapid development of my country's pesticide industry, the wastewater in the pesticide chemical industry has a high concentration and contains a lot of salt, but many enterprises have imperfect wastewater treatment facilities, or even no treatment facilities, and some enterprises have excessive investment in wastewater treatment settings and excessive operating costs. High, and unable to meet the standard stably

After traditional distillation of agrochemical high-concentration saline wastewater from many enterprises, the salt mixture is complicated and contains a large amount of impurities, which cannot meet the application standards of industrial salt. The distilled water still contains some salt, which is not good for subsequent processing

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0031] The present invention will be further described below with reference to the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention.

[0032] The wastewater is taken from agrochemical high-concentration salt-containing wastewater discharged by a pesticide company in Shandong. The water quality is as follows:

[0033]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

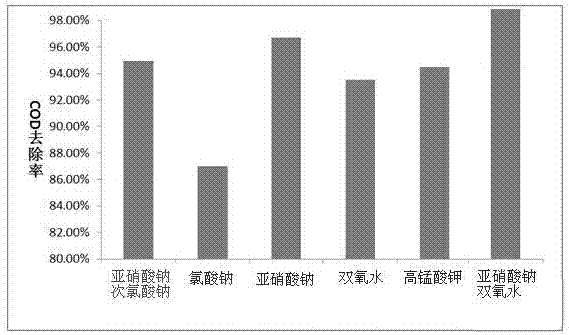

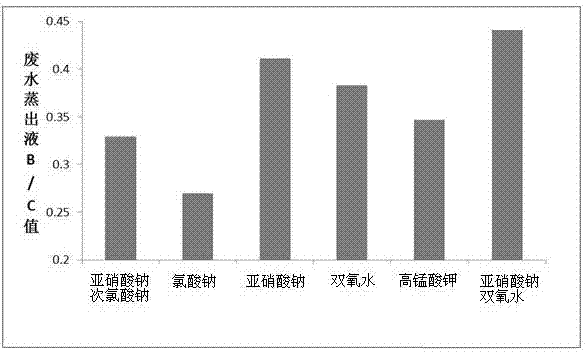

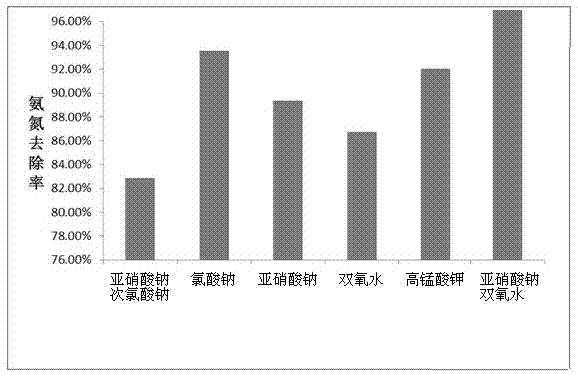

The invention relates to the field of wastewater treatment and specifically relates to a treatment process of agrochemical high-concentration salt-containing wastewater. The treatment process comprises the following steps: filtering the agrochemical high-concentration salt-containing wastewater, then regulating the pH to 7-8, and uniformly stirring; pumping the wastewater into an MVR (mechanical vapor recompression) evaporation, adding catalysts, namely sodium nitrite and hydrogen peroxide, introducing oxygen, and evaporating till saturation at the evaporation temperature of 90-100 DEG C; and transferring a saturated concentrated solution into a crystallization kettle for concentration and crystallization, separating out sodium chloride, then separating, and returning liquid after separation into the MVR evaporation for applying mechanically. The treatment process provided by the invention has the beneficial effects that the process adopts the special catalysts and equipment, the removal rate of COD (chemical oxygen demand) in the wastewater can be as high as 98%, the removal rate of ammonia nitrogen can be as high as 96%, the B / C value of the wastewater can achieve 0.40, the biochemical property of the wastewater is relatively high, the further treatment can be performed, water resources are enriched, and the content of sodium chloride in residues can be as high as 98.38% and is in line with the industrial salt standard; furthermore, by combining the MVR with the method, the MVR can only consume electric energy, 25-35 degrees of electricity can be consumed for evaporating 1 ton of wastewater, and the energy is further saved.

Description

technical field [0001] The invention relates to the field of wastewater treatment, in particular to an agrochemical high-concentration saline wastewater treatment process. Background technique [0002] After a lot of research, investigation and data review, it is found that the agrochemical high-concentration saline wastewater is gradually increasing in China. Moreover, various treatment technologies are affected by various factors, and the treatment pressure is also increasing. At present, my country has not yet truly suitable for the treatment of agrochemical high-concentration saline wastewater, and all processes are immature. The treatment scheme is basically the traditional or improved activated sludge method, electrochemistry, electrodialysis membrane method, traditional distillation method and other processes. These processes all have certain defects. The separated salt is mixed and contains a large amount of impurities, which cannot be used in industrial salt applica...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C02F9/10C01D3/06

Inventor 王宗赵伟刘泉民韦能春戴荣华曹同波房立彬苑敬林魏国强

Owner JINGBO AGROCHEM TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com