Polyol-ester-modified silicone oil and preparation method thereof, carbon fiber oil solution

A technology of polyol ester and modified silicon, which is applied in the fields of carbon fiber, fiber treatment, textiles and papermaking, etc., can solve the problems of poor micro-compatibility and affecting the quality of carbon fiber, achieve good compatibility, avoid micro-phase separation, reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~25

[0035] Embodiment 1~25 is the preparation method example of polyol ester modified silicone oil

Embodiment 1

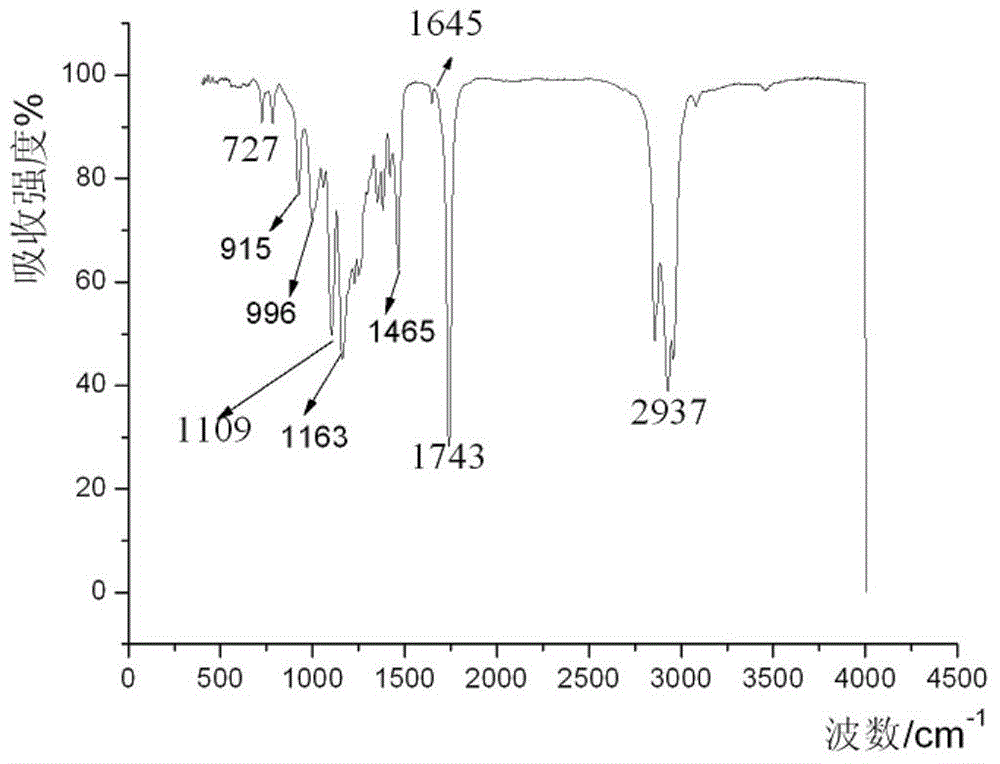

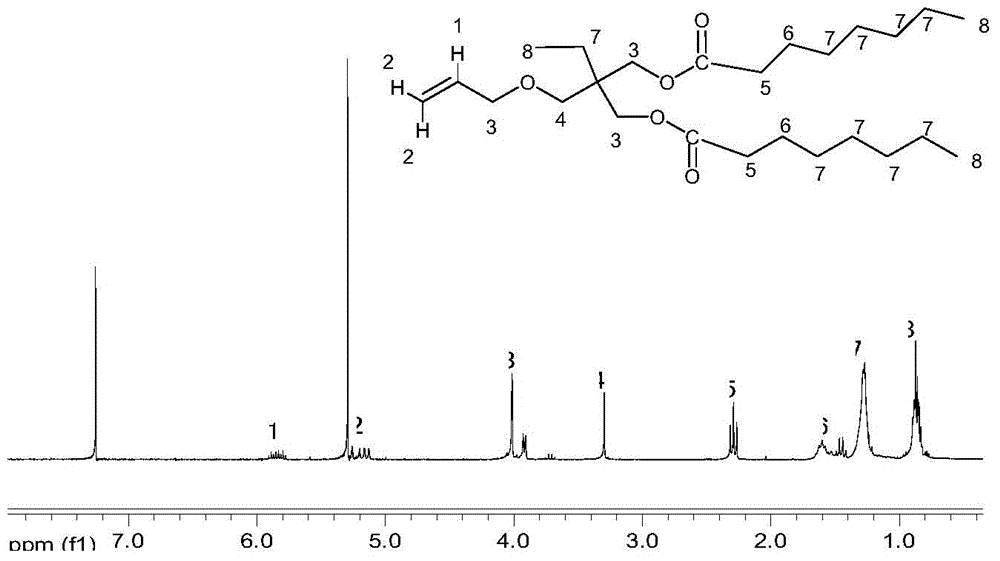

[0037] Add 26.1g of trimethylolpropane monoallyl ether, 60mL of toluene, and 52.5mL of triethylamine into a 250mL three-neck flask equipped with a condenser tube and a drying tube, stir and cool to 5°C under an ice-water bath, and slowly add 56.4mL of Octanoyl chloride, after the dropwise addition, continued to stir for 6h to complete the reaction. After the reaction finishes, filter off the triethylamine hydrochloride generated, and use 20mL of 10% NaHCO 3 Wash once with aqueous solution, wash with water until neutral, anhydrous Mg 2 SO 4 After drying, the solvent was distilled off under reduced pressure to obtain light yellow trimethylolpropane allyl ether dicaprylate with a yield of 94%.

Embodiment 2~5

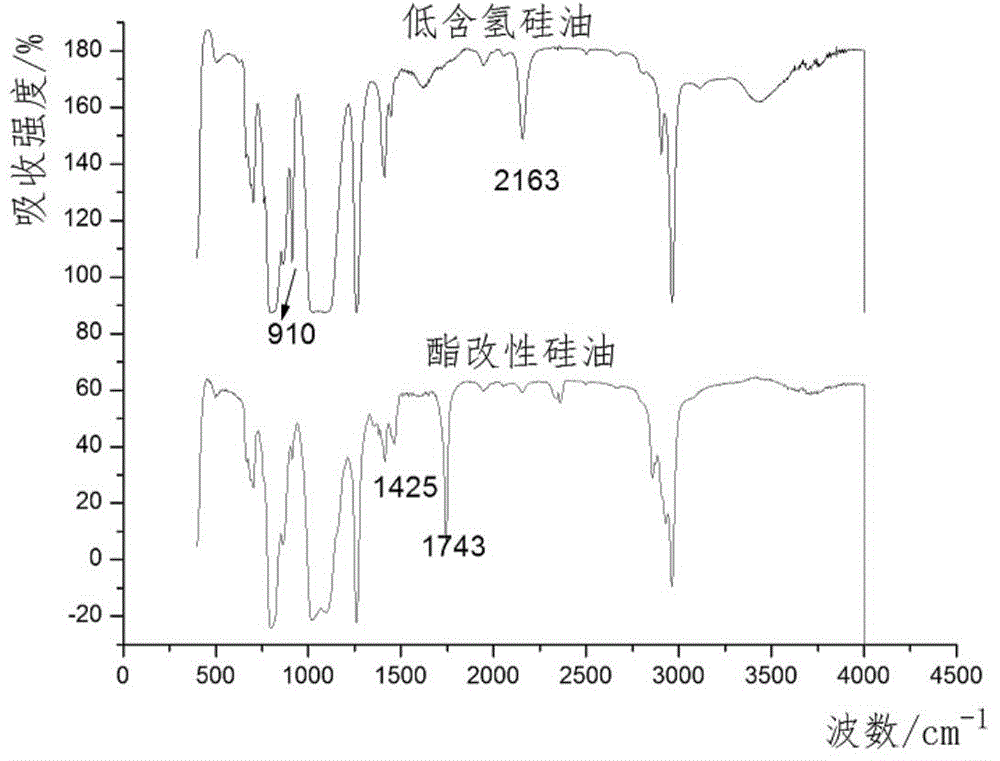

[0039] According to a certain ratio, the trimethylolpropane allyl ether dicaprylate, toluene and catalyst (5% by mass percentage of chloroplatinic acid isopropanol solution) synthesized in Example 1 were added into the In the three-necked 500mL flask of the tube and the constant pressure dropping funnel, put 90g of low-hydrogen silicone oil (hydrogen content is 0.09, viscosity is about 700mPa·s, self-made according to the literature, the literature is: Ma Fengguo, Liu Chunxia, Shen Wenling, high hydrogen-containing silicone oil Research on the preparation of low-hydrogen silicone oil by telomerization method, Silicone Materials, 2010, 24, 356-359) was diluted with toluene to a solution with a mass percentage of 60%, and then added to a constant pressure dropping funnel, started the stirrer, and Under protection, the temperature was raised to 90-100°C, and the diluted low-hydrogen-containing silicone oil was added dropwise to the reaction bottle within 1-1.5 hours, and then re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com