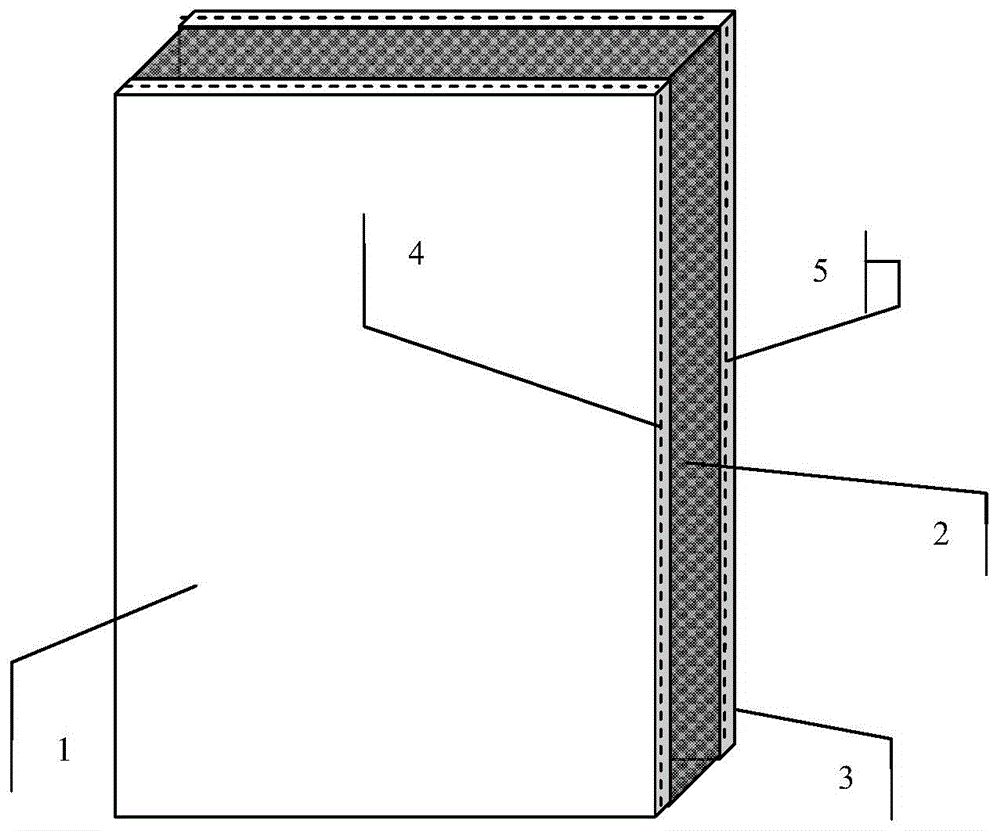

"Pomegranate-type" fireproof thermal insulation plate, preparation method thereof and composite thermal insulation plate

A fire-proof insulation board, pomegranate-style technology, applied in the direction of insulation, fire prevention, building components, etc., can solve the problems of construction difficulty, large capacity, high cost, etc., and achieve the effect of solving flammability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0045] The ordinary grade E-303 expandable polystyrene particles were pre-expanded for 30 minutes under a steam pressure of 0.05 MPa to obtain polystyrene beads with a particle diameter of 4-6 mm, counting as 50 parts.

[0046] Mix 40 parts of 40% concentration silica sol, 7 parts of 3000mPa·s phenolic resin, 3 parts of microencapsulated red phosphorus flame retardant, stir well with the additives, and pour them together with 50 parts of pre-released polystyrene beads Mix with a mixer and coat evenly, then put it in a 70°C oven for 20 minutes and take it out.

[0047] The cured film-coated beads were molded under 0.15MPa steam pressure for 10 minutes, and cut to obtain a "pomegranate" fireproof insulation board. The obtained insulation board did not drip when burned, and the limiting oxygen index was 24.8%.

example 2

[0049] The ordinary grade E-501 expandable polystyrene particles were pre-expanded for 18 minutes under the steam pressure of 0.2 MPa to obtain polystyrene beads with a particle diameter of 3-5 mm, counting as 65 parts.

[0050] Mix modulus 2.8, 10 parts of sodium silicate with a concentration of 15%, 20 parts of 2000mPa·s phenolic resin, 2 parts of aluminum hydroxide flame retardant, 3 parts of expandable graphite flame retardant, and mix well with additives, and mix with 65 Pour the pre-issued polystyrene beads into the mixer to mix and coat evenly, and then put them in an oven at 105°C for 7 minutes and take them out.

[0051] The cured film-coated beads were molded under 0.1MPa steam pressure for 20 minutes, and cut to obtain a "pomegranate" fireproof insulation board. The obtained insulation board did not drip when burned, and the limiting oxygen index was 26.2%.

example 3

[0053] The flame-retardant grade F-302 expandable polystyrene particles were pre-expanded under 0.35 MPa steam pressure for 8 minutes to obtain polystyrene beads with a particle size of 2-4 mm, which was counted as 45 parts.

[0054] Mix modulus 3.1, 20 parts of potassium silicate with a concentration of 25%, 20 parts of silica sol with a concentration of 30%, 5 parts of 1000mPa·s urea-formaldehyde resin, 5 parts of magnesium hydroxide flame retardant, 5 parts of phosphate ester flame retardant, and auxiliary After the agent is fully stirred evenly, pour it into the mixer together with 45 parts of pre-released polystyrene beads to mix and coat evenly, and then put it in a 90°C oven for 15 minutes and take it out.

[0055] The cured film-coated beads were molded under 0.35MPa steam pressure for 12 minutes, and then cut to obtain a "pomegranate" fireproof insulation board. The obtained insulation board did not drip when burned, and the limiting oxygen index was 22.7%.

[0056] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com