Supermolecule corrosion inhibitor for copper and copper alloy and high-speed mixing preparation method thereof

A corrosion inhibitor and supramolecular technology, applied in the field of corrosion inhibitor of copper and its alloys and its high-speed stirring preparation, can solve the problem that the effect is not fully manifested, and achieve excellent anti-corrosion effect, strong universality, and water solubility. sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

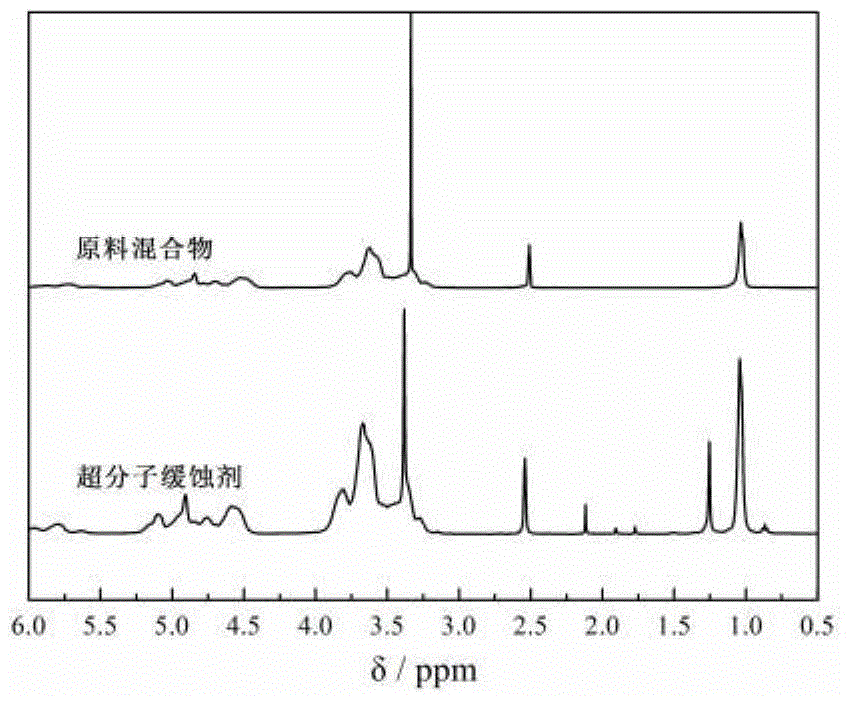

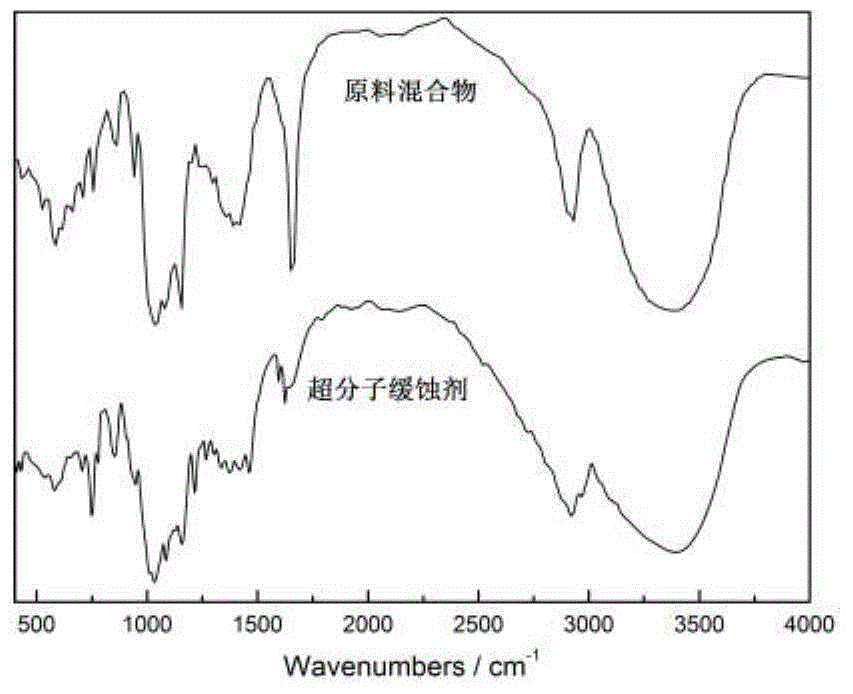

[0023] At a stirring rate of 300rpm, mix 15g of β-cyclodextrin and 48ml of water at 60°C. After completely dissolving, continue stirring for 30min; mix 3.8g of benzothiazole and 10mL of absolute ethanol, and then slowly pour into In the cyclodextrin solution, the temperature is then controlled at 40°C, and the stirring rate is adjusted to 1000rpm and stirred for 1 hour to obtain a homogeneous system, that is, to obtain a supramolecular corrosion inhibitor for copper and its alloys. The corrosion inhibitor is β with a hydrophobic cavity. -Cyclodextrin and benzothiazole are induced by absolute ethanol and bonded through weak intermolecular interactions to form clathrates with a supramolecular structure.

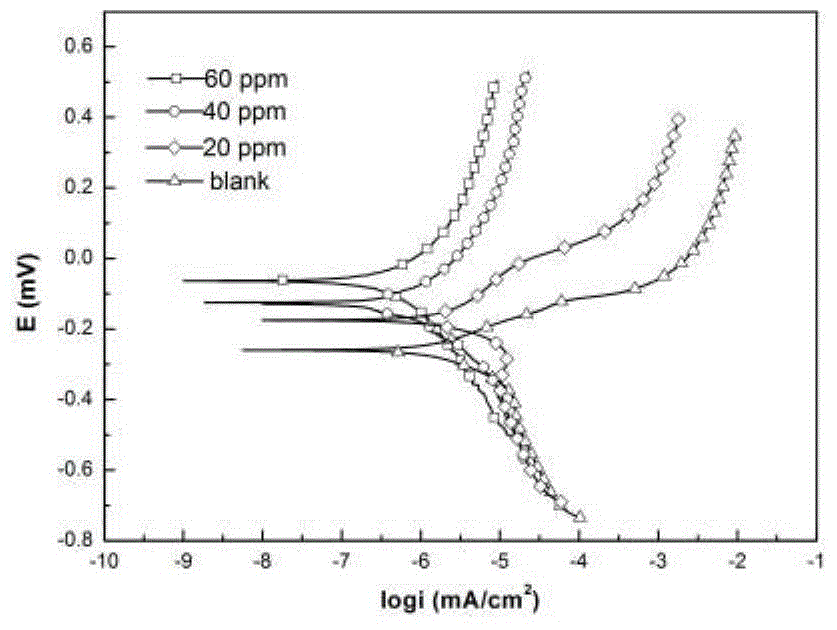

[0024] Put the above-mentioned supramolecular corrosion inhibitors of copper and its alloys into industrial condensed water in amounts of 20, 40, and 60 mg / L respectively, and the electrochemical polarization curve of the copper electrode is as follows: image 3 shown. Put the...

Embodiment 2

[0026] At a stirring rate of 500rpm, mix 18g of methyl-β-cyclodextrin and 40ml of water at 50°C, and continue stirring for 10min after completely dissolving; mix 5.6g of benzimidazole and 7mL of ethylene glycol, and then slowly Pour into the methyl-β-cyclodextrin solution, then control the temperature at 60°C, and adjust the stirring speed to 800rpm and stir for 2 hours to obtain a homogeneous system, that is, to obtain a supramolecular corrosion inhibitor for copper and its alloys, the corrosion inhibitor It is an inclusion compound with a supramolecular structure formed by methyl-β-cyclodextrin with a hydrophobic cavity and benzimidazole induced by ethylene glycol and combined through weak intermolecular interactions.

[0027] The supramolecular corrosion inhibitor of copper and its alloys prepared above is put into industrial condensate water and circulating cooling water in an amount of 20mg / L, and the corrosion rate of copper and its alloys is less than 0.005mm / a.

Embodiment 3

[0029] At a stirring rate of 450rpm, mix 10g of hydroxypropyl-β-cyclodextrin and 23mL of water at 45°C, and continue stirring for 30min after completely dissolving; mix 2.8g of benzotriazole with 3.8mL of glycerin Uniform, then slowly added to the hydroxypropyl-β-cyclodextrin solution, then the temperature was controlled at 55°C, and the stirring rate was adjusted to 1200rpm and stirred for 0.5h to obtain a homogeneous system, that is, supramolecular corrosion inhibition of copper and its alloys agent, the corrosion inhibitor is hydroxypropyl-β-cyclodextrin with a hydrophobic cavity and benzotriazole induced by glycerol and combined with a weak interaction between molecules to form a supramolecular structure clathrate.

[0030] The supramolecular corrosion inhibitor of copper and its alloys prepared above is put into industrial condensate water and circulating cooling water in an amount of 30mg / L, and the corrosion rate of copper and its alloys is less than 0.005mm / a.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com