Environmental protection type metal detergency liquid

A decontamination liquid and metal technology, applied in the field of cleaning agents, can solve the problems of environmental hazards, complex processes, high cost, and achieve strong degreasing effect and low corrosive effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

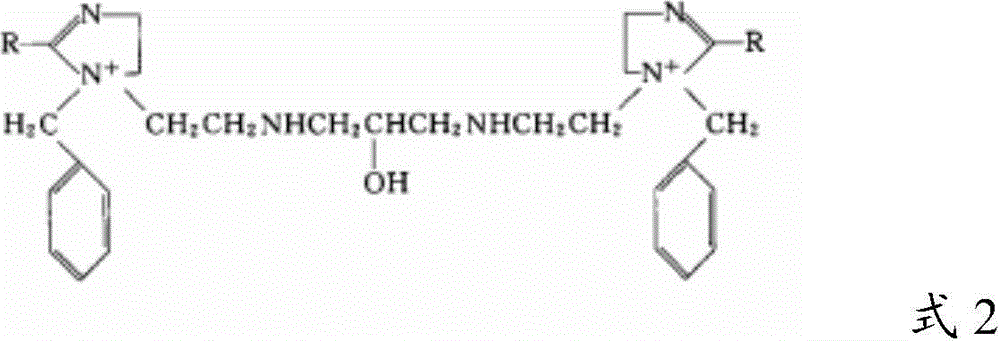

[0035] The preparation method of described gemini cation imidazoline quaternary ammonium salt is specifically:

[0036] The first step, get 34.8g oleic acid and 15.3g diethylenetriamine, 0.2g aluminum sesquioxide catalyst and put into the there-necked flask that thermometer, reflux condenser and water separator are housed, add water-carrying agent xylene simultaneously 40ml, using 140°C, 170°C, 220°C stepwise heating method, dehydration until no more water is formed, then reduce to 140°C for vacuum distillation, remove xylene, generate amide and cyclize to obtain imidazoline intermediate;

[0037] In the second step, add the imidazoline intermediate and benzyl chloride into a three-necked flask at a molar ratio of 1:1, install a condenser tube and a thermometer, stir and heat up to 90°C to 110°C for 4 hours, and then add 4ml of epichlorohydrin , keep the temperature constant, continue to react for 5h, cool to room temperature, get the crude product, recrystallize 5 times with ...

Embodiment 1

[0043] The preparation of embodiment 1 gemini cation imidazoline quaternary ammonium salt

[0044] Get 34.8g oleic acid and 15.3g diethylenetriamine, 0.2g aluminum sesquioxide catalyst and put into the three-necked flask that thermometer, reflux condenser and water separator are housed, add water-carrying agent xylene 40ml simultaneously, adopt 140 ℃, 170°C, 220°C stepwise heating method, dehydration until no more water is generated, reduce to 140°C for vacuum distillation, remove xylene, generate amides and cyclize to obtain imidazoline intermediates; imidazoline intermediates Add benzyl chloride to a three-necked flask at a molar ratio of 1:1, install a condenser tube and a thermometer, stir and raise the temperature to 90°C-110°C for 4 hours, then add 4ml of epichlorohydrin, keep the temperature constant, and continue the reaction for 5 hours , cooled to room temperature to obtain a crude product, which was recrystallized five times with acetone / isopropanol, and dried in va...

Embodiment 2

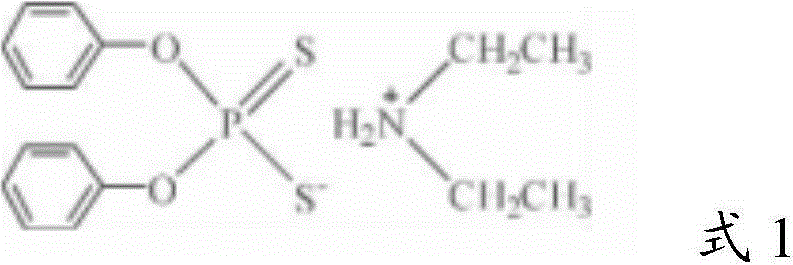

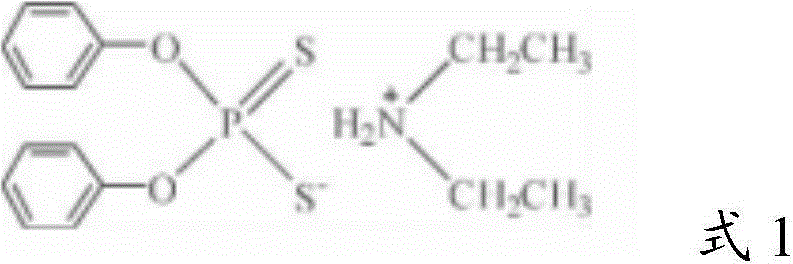

[0045] Embodiment 2O', the preparation of O'-diphenyldithiophosphoric acid-N,N-diethylamine

[0046] Add 22.2g of phosphorus pentasulfide (0.1mol) and 37.6g of phenol (0.4mol) into a 250mL three-necked flask, and add 70mL of toluene as a solvent; while stirring, gradually raise the temperature to about 100°C and react for 45min; then raise the temperature until reflux, reflux 3h, the solid gradually disappeared during the reaction; the solution was slightly cold, boiled with a small amount of activated carbon to decolorize, filtered while it was hot, and the filtrate was cooled to room temperature; the obtained filtrate was transferred to a beaker, cooled in a water bath, and 22 mL of diethylamine was added drop by drop under stirring (0.2mol), the reaction system emits a large amount of heat, and the color of the liquid gradually becomes orange-red. When stirred rapidly with a glass rod, precipitation occurs, and it is left standing overnight at room temperature; filtered unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com