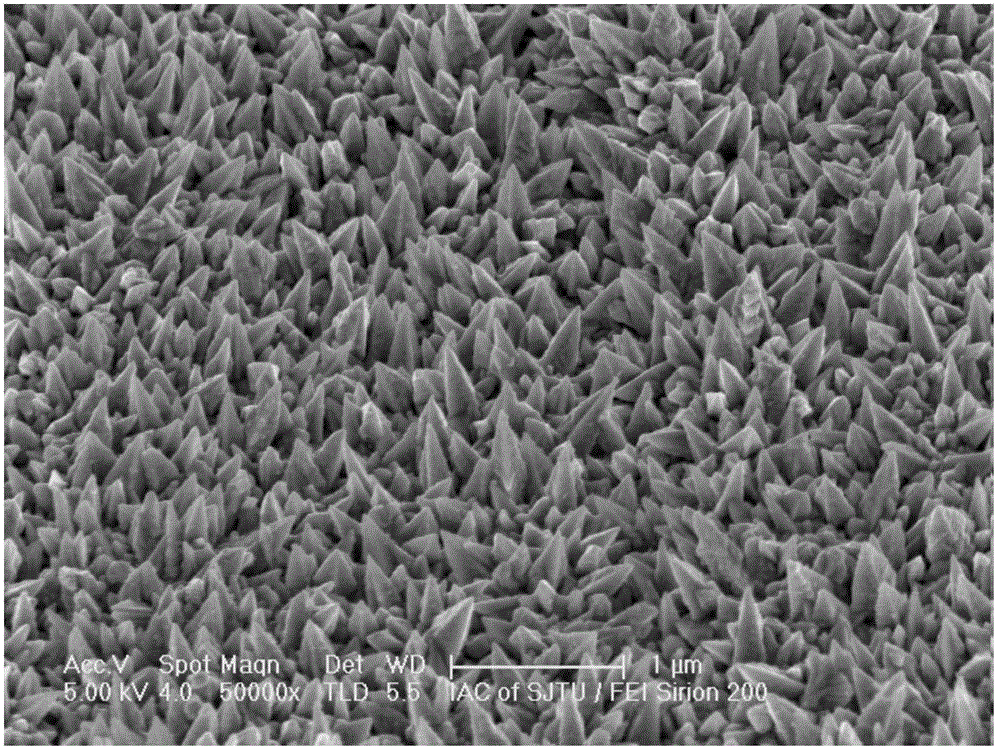

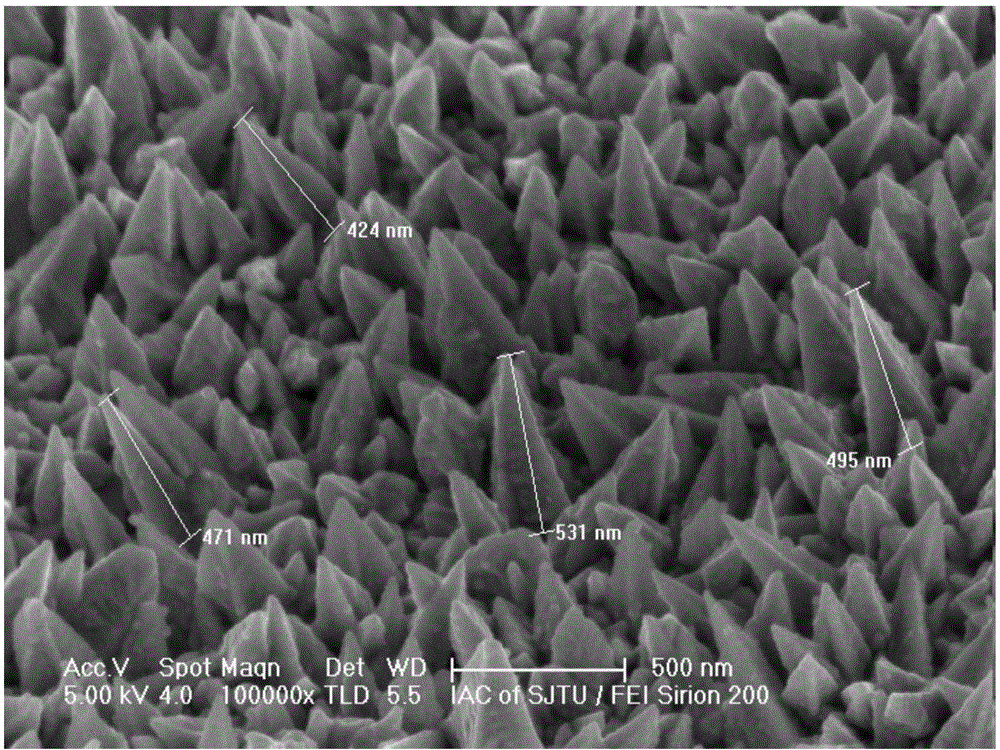

Method for preparing micro-nano needle conical structure for copper interconnection by electrochemical deposition

A copper interconnection and micro-nano technology, which is applied in the cross field of micro-nano and electrochemistry, can solve the problems of expensive production, high process cost, and difficulty in large-scale industrial production, and achieve the effect of low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This embodiment relates to a method for preparing a micro-nano needle-cone structure for copper interconnection by electrochemical deposition, and the specific steps are as follows:

[0028] (1) Degrease and derust the copper plate substrate whose surface needs to form a micro-nano needle crystal array structure. The degreasing refers to the removal of organic substances such as oil stains adhering to the surface of the substrate; the derusting refers to the removal of inorganic substances such as the oxide layer on the surface of the substrate.

[0029] (2) Place the base material pre-treated in step (1) in the following electroplating solution, and use the base material as the cathode, and use the copper plate or the insoluble pole plate as the anode, and make the base material, the copper plate (or the insoluble plate) plate) and the electroplating power supply form a loop.

[0030] The electroplating solution used in the present embodiment consists of: copper metha...

Embodiment 2

[0034] This embodiment relates to a method for preparing a micro-nano needle-cone structure for copper interconnection by electrochemical deposition, and the specific steps are as follows:

[0035] (1) Degrease and derust the copper plate substrate whose surface needs to form a micro-nano needle crystal array structure.

[0036] (2) Place the base material pre-treated in step (1) in the following electroplating solution, and use the base material as the cathode, and use the copper plate or the insoluble pole plate as the anode, and make the base material, the copper plate (or the insoluble plate) plate) and the electroplating power supply form a loop.

[0037] The electroplating solution used in this embodiment consists of: copper methanesulfonate 1.5mol / L, copper pyrophosphate 0.5mol / L, ethylenediamine 2mol / L, boric acid 0.3mol / L, additives SPS15ppm, PEG1600ppm, JGB40ppm, solution temperature It is 20°C and the pH value is 5.0.

[0038] (3) Apply direct current to the subst...

Embodiment 3

[0041] This embodiment relates to a method for preparing a micro-nano needle-cone structure for copper interconnection by electrochemical deposition, and the specific steps are as follows:

[0042] (1) Degrease and derust the copper plate substrate whose surface needs to form a micro-nano needle crystal array structure.

[0043] (2) Place the base material pre-treated in step (1) in the following electroplating solution, and use the base material as the cathode, and use the copper plate or the insoluble pole plate as the anode, and make the base material, the copper plate (or the insoluble plate) plate) and the electroplating power supply form a loop.

[0044]The electroplating solution used in this embodiment consists of: copper methanesulfonate 1.5mol / L, copper nitrate 0.25mol / L, ethylenediamine 1mol / L, boric acid 0.3mol / L, additive SPS100ppm, PEG500ppm, JGB1400ppm, solution temperature is 30°C, pH value is 2.5.

[0045] (3) Apply direct current to the substrate through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com