Method for preparing Dawson heteropolyphosphatotungstate

A technology of phosphotungstoheteropolysalt and tungstate, which is applied in the direction of phosphorus oxyacid, can solve problems such as waste of raw materials, unresolved use problems, and equipment corrosion, so as to reduce equipment corrosion and reduce environmental pollution and safety hazards, yield and purity improvements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

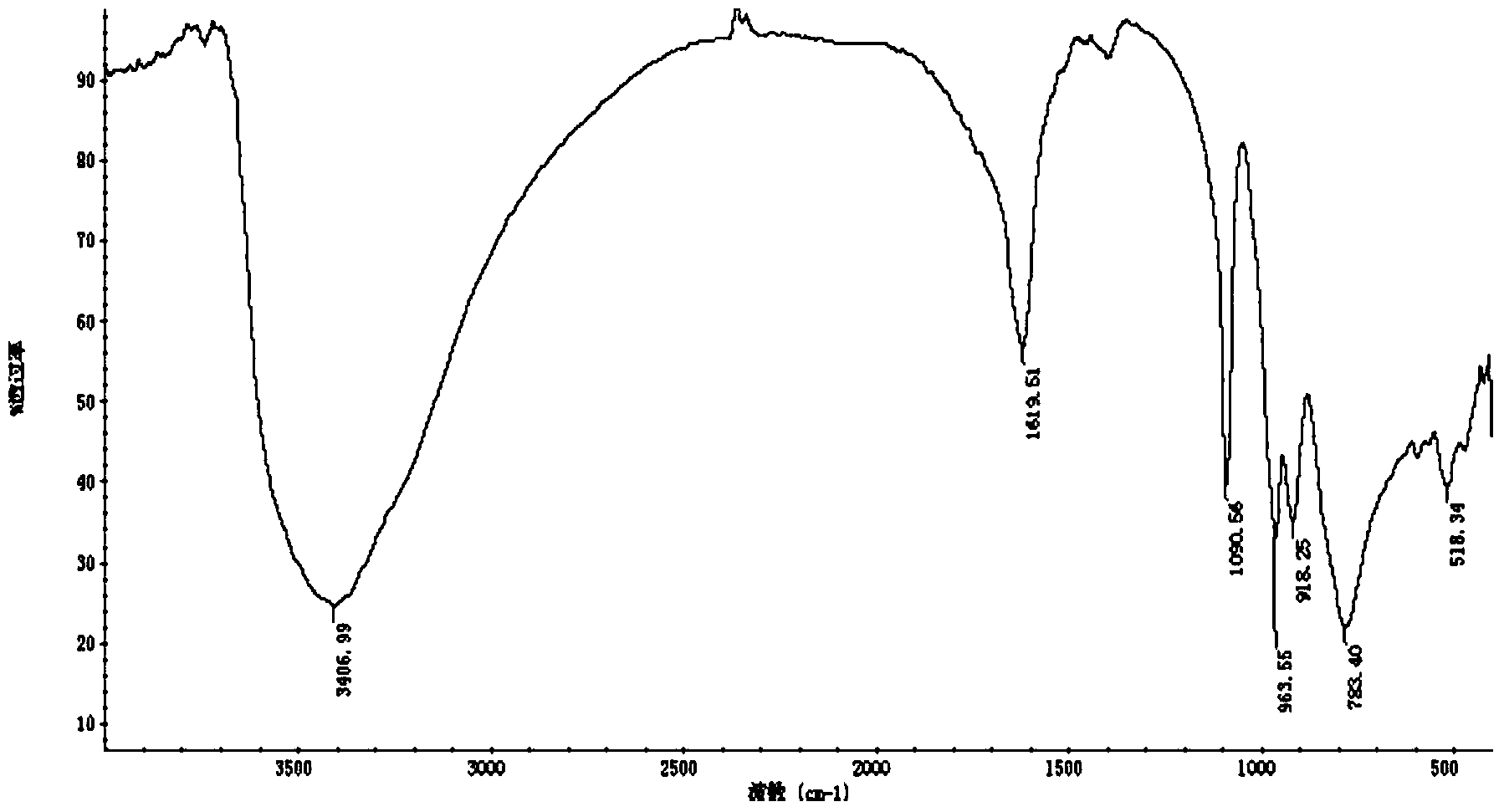

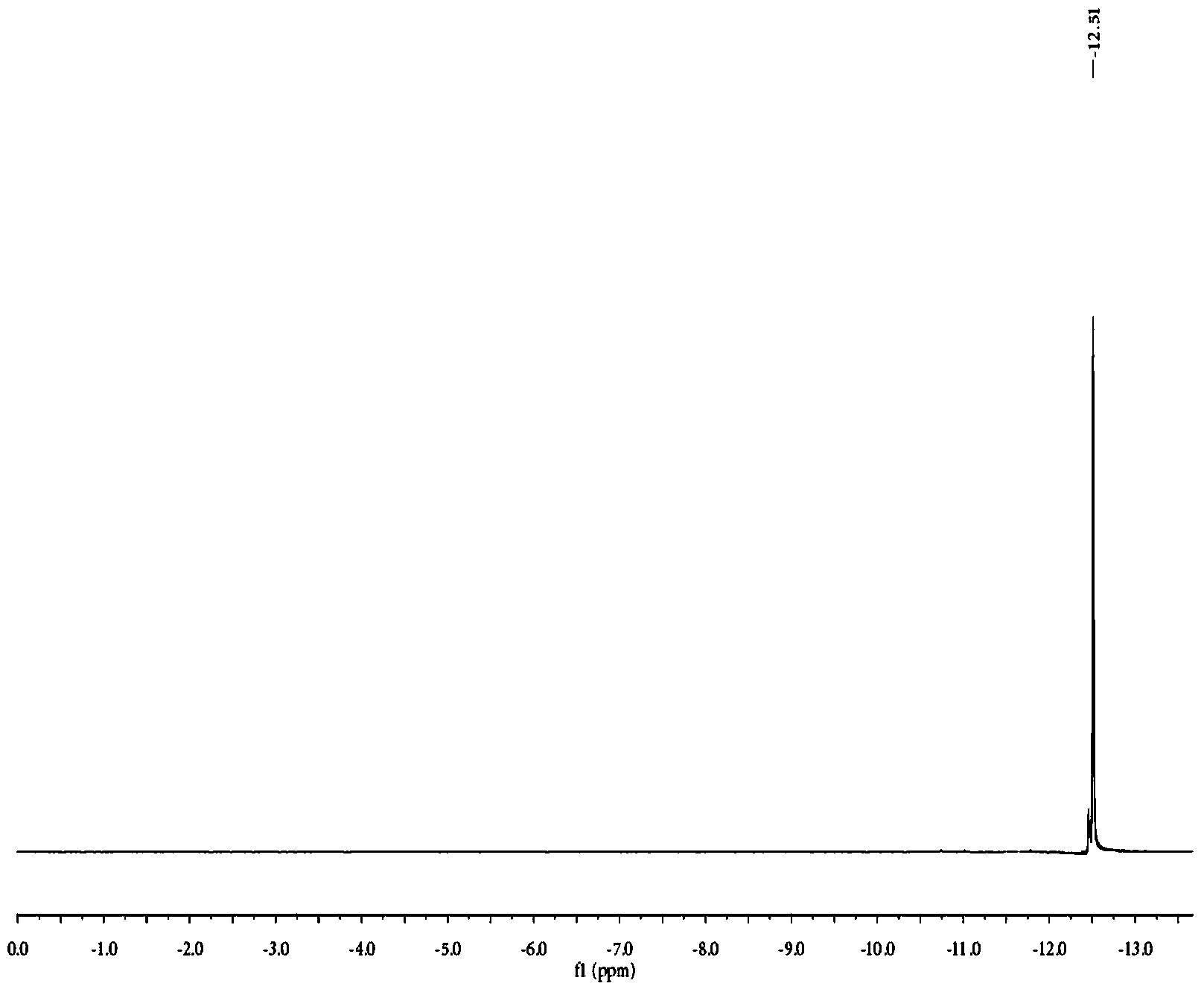

[0040] Weigh 30 grams of sodium tungstate dihydrate, add 50ml of deionized water, and stir until the sodium tungstate is completely dissolved; adjust the pH of the solution to 7.0 with 1mol / L hydrochloric acid; continue to adjust the solution to pH 1.0 with 1.5mol / L phosphoric acid After stirring for 1 hour, transfer to a 100ml autoclave with PTFE lining and heat at 100°C for 10 hours; after natural cooling, transfer the solution to a beaker, add potassium chloride to nearly saturation, and stir for 1 hour; Purify, filter and dry to constant weight to obtain 23.1 g of light yellow product, press K 6 [P 2 W 18 O 62 ]·14H 2 Based on O, the yield is about 94.3%. See the FT-IR spectrum of the product figure 1 , It can be seen that the product is at 1090cm -1 , 963cm -1 918cm -1 783cm -1 There is an obvious absorption peak, which is completely consistent with the FT-IR spectrum of the Dawson-type potassium phosphotungstate standard; 31 P-NMR nuclear magnetic resonance spectrum see f...

Embodiment 2

[0042] Weigh 30 grams of sodium tungstate dihydrate, add 25ml of deionized water, and stir until the sodium tungstate is completely dissolved; adjust the pH of the solution to 6.5 with 1mol / L hydrochloric acid; continue to adjust the solution to pH 1.0 with 5mol / L of phosphoric acid; After stirring for 1 hour, transfer to a 100ml autoclave with PTFE lining and heat at 120°C for 10 hours; after natural cooling, transfer the solution to a beaker, add potassium chloride to nearly saturation, and stir for 1 hour; purification , Filter and dry to constant weight to obtain 22.6 grams of light yellow product, press K 6 [P 2 W 18 O 62 ]·14H 2 Based on O, the yield is about 92.2%. The FT-IR spectrum of the sample phosphotungstic acid and 31 P-NMR nuclear magnetic resonance spectra are respectively figure 1 , figure 2 similar.

Embodiment 3

[0044] Weigh 30 grams of sodium tungstate dihydrate, add 50ml of deionized water, and stir until the sodium tungstate is completely dissolved; adjust the pH of the solution to 7.0 with 1mol / L hydrochloric acid; continue to adjust the solution to pH 0.5 with 10mol / L phosphoric acid; After stirring for 1 hour, transfer to a 100ml autoclave lined with polytetrafluoroethylene, and heat at 120°C for 4 hours; after natural cooling, transfer the solution to a beaker, add potassium chloride to nearly saturation, and stir for 1 hour; purification , Filter and dry to constant weight to obtain 21.9 grams of light yellow product, press K 6 [P 2 W 18 O 62 ]·14H 2 Based on O, the yield is about 89.4%. The FT-IR spectrum of the sample phosphotungstic acid and 31 P-NMR nuclear magnetic resonance spectra are respectively figure 1 , figure 2 similar.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com