Method for extracting multiple functional components from wheat starch processing wastewater

A technology for processing waste water and wheat starch, which is applied to peptide preparation methods, chemical instruments and methods, water/sewage multi-stage treatment, etc. It can solve the problems that economic, social and ecological benefits are not fully reflected

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

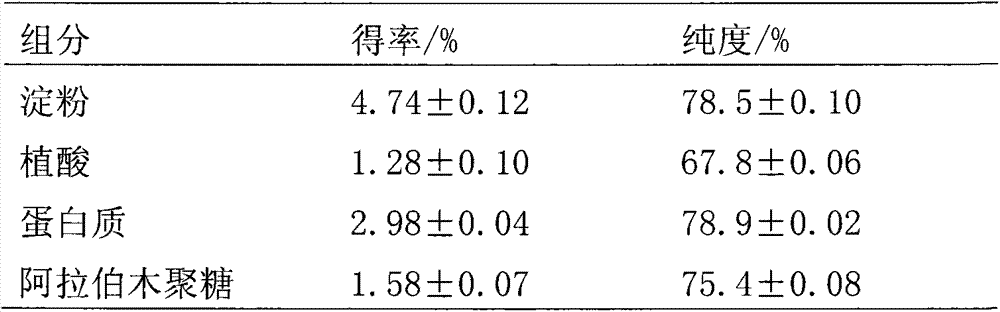

[0025] Example 1. Co-extracting various functional components from wheat starch processing wastewater

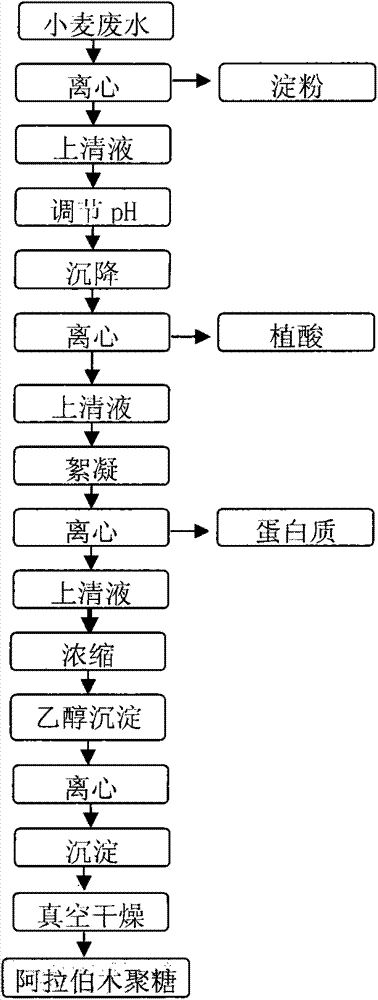

[0026] 1. Extraction process

[0028] Take 1000mL of wheat starch processing wastewater and centrifuge it in a desktop centrifuge with a centrifugal force of 3500g and a centrifugation time of 25min. Collect the centrifuged precipitate and supernatant respectively, and dry the precipitate by vacuum drying to obtain a starch product.

[0029] 2) Phytic acid extraction

[0030] Use 1.5M potassium hydroxide (KOH) to adjust and remove starch centrifugation supernatant to pH 7.5; let it settle for 1.5h; use a desktop centrifuge for centrifugation with a centrifugal force of 4000g and a centrifugation time of 35min; collect the centrifugal sediment and supernatant respectively, and precipitate Vacuum drying is adopted to obtain the phytic acid product.

[0031] 3) Protein extraction

[0032] In the centrifugation supernatant of phytic acid, add comp...

Embodiment 2

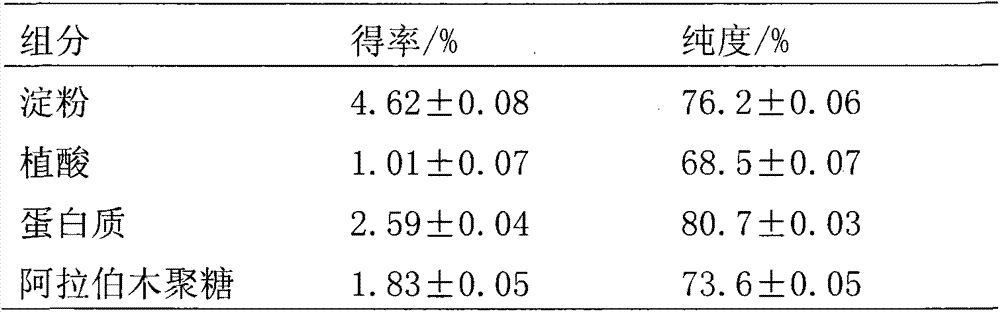

[0047] Example 2 Co-extraction of multiple functional components from wheat starch processing wastewater

[0048] 1. Extraction process

[0050] Take 10L of wheat starch processing wastewater and centrifuge with a three-legged centrifuge with a centrifugal force of 5000g and a centrifugation time of 20min to collect the centrifugal precipitate and supernatant respectively, and vacuum dry the precipitate to obtain a starch product.

[0051] 2) Phytic acid extraction

[0052] Use 1.0M Potassium Hydroxide (KOH) to adjust and remove the starch centrifugation supernatant to pH 7.0; let it settle for 1.0h; use a three-legged centrifuge for centrifugation with a centrifugal force of 6000g and a centrifugation time of 25min; collect the centrifugal sediment and supernatant respectively, The precipitate is dried by vacuum drying method to obtain phytic acid product.

[0053] 3) Protein extraction

[0054] In the centrifugation supernatant of phytic acid,...

Embodiment 3

[0069] Example 3 Co-extraction of multiple functional components from wheat starch processing wastewater

[0070] 1. Extraction process

[0072] Take 100L of wheat starch processing wastewater and centrifuge in a three-legged centrifuge with a centrifugal force of 4000g and a centrifugation time of 15min to collect the centrifuged precipitate and supernatant respectively, and vacuum dry the precipitate to obtain a starch product.

[0073] 2) Phytic acid extraction

[0074] Use 1.5M Potassium Hydroxide (KOH) to adjust and remove the starch centrifugation supernatant to pH 7.3; let it settle for 2.0h; use a three-legged centrifuge for centrifugation with a centrifugal force of 5000g and a centrifugation time of 30min; collect the centrifugal sediment and supernatant respectively, The precipitate is dried by vacuum drying method to obtain phytic acid product.

[0075] 3) Protein extraction

[0076] In the centrifugation supernatant of phytic acid, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com